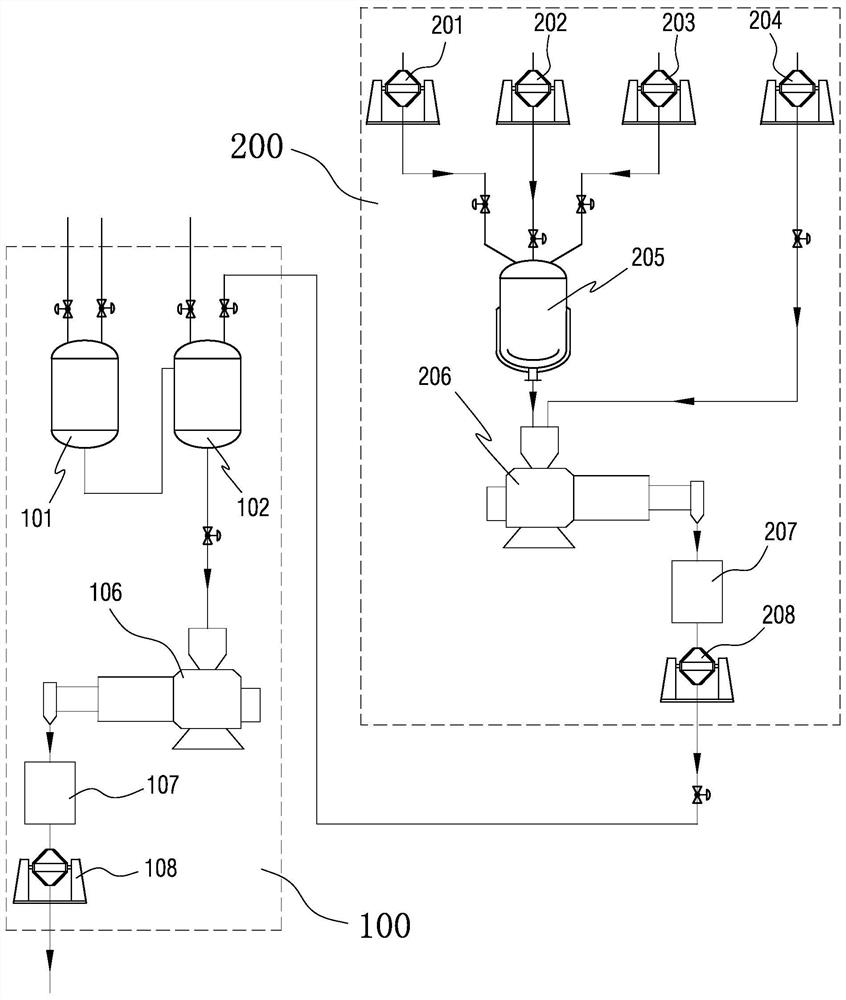

A functional masterbatch production system for polyester film

A technology of functional masterbatch and production system, which is applied in the field of functional masterbatch production system for polyester film, can solve the problems of great influence on the quality of polyester film, achieve excellent transparency, strength and excellent flame retardant performance, Even shrinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation of the polyester carrier of the present application, taking PET as an example, preferably produces bishydroxyethyl terephthalate through esterification or transesterification of terephthalic acid or dimethyl terephthalate and ethylene glycol, by It is industrially produced by a polycondensation method in which a catalyst is used for polycondensation under high temperature and vacuum. In a specific embodiment, terephthalic acid, ethylene glycol, cyclohexanedimethanol, catalyst and heat stabilizer can be used as raw materials for esterification; or terephthalic acid, ethylene glycol, isophthalic acid , catalyst and heat stabilizer as raw materials for esterification. In another specific embodiment, the catalyst is any compound of Ti / Si non-heavy metal catalyst and antimony trioxide, and the added amount thereof is 0.01-0.09% of the weight of the polyester. In another specific embodiment, the heat stabilizer is a phosphoric acid compound, and its addition ...

Embodiment 1

[0046] Dry 60 parts by weight of airgel particles with a particle size of 0.5 μm at 120 ° C for 4 hours; dry 10 parts by weight of polylactic acid particles with a particle size of 0.5 mm or less at 110 ° C for 4 hours; Polystyrene particles below mm and 5 parts by weight of polyethylene particles below 0.5 mm were dried at 110° C. for 4 hours. The above-mentioned dried particles are put into 30 parts by weight of liquid polydimethylsiloxane at room temperature and stirred at high speed for 2 hours to obtain a paste material, and the stirring speed is 1000-1500 rpm. 20 parts by weight of polystyrene granules and 5 parts by weight of polyethylene granules dried at 110°C for 4 hours (you don't need to pulverize here, just dry them in the form of purchased granules), and put them into extrusion with the above paste. In the mixing area of the machine, after uniform mixing, melt extrusion, pelletizing, and drying to obtain functional material slices.

[0047] Add terephthalic ac...

Embodiment 2

[0050] Dry 70 parts by weight of airgel particles with a particle diameter of 10 μm at 120 ° C for 4 hours; dry 15 parts by weight of polylactic acid particles with a particle size of 0.5 mm or less at 110 ° C for 4 hours; The following polystyrene pellets were dried at 110°C for 4 hours. The above-mentioned dried particles are put into 40 parts by weight of liquid polydimethylsiloxane at room temperature and stirred at high speed for 2 hours to obtain a paste material at a stirring speed of 1000-1500 rpm. Put 45 parts by weight of polystyrene granules dried at 110°C for 4 hours (here, you don’t need to pulverize them, just dry them in the form of purchased granules), and put them into the mixing area of the extruder with the above-mentioned paste material, and evenly After mixing, it is melt-extruded, pelletized, and dried to obtain slices of functional materials.

[0051] Add terephthalic acid, ethylene glycol, and germanium dioxide into the esterification reaction kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com