Nano filler and epoxy composite insulating material and preparation method thereof, and epoxy composite insulating component

A nano-filler and composite insulation technology, applied in the field of nano-materials, can solve the problems of poor vacuum surface flashover performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The embodiment of the present application provides Al 2 o 3 / TiO 2 The nano-filler with core-shell structure, epoxy composite insulating material and epoxy composite insulating part, the specific preparation method is as follows:

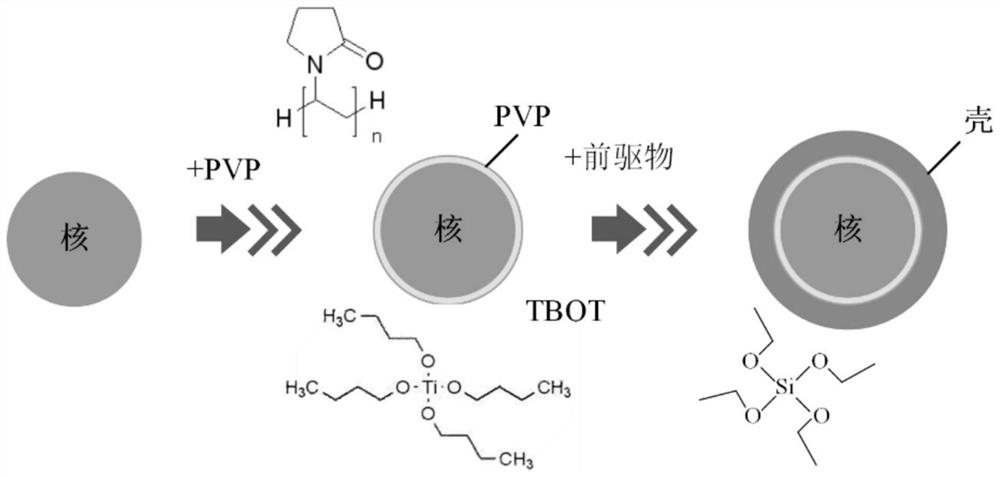

[0069] 1. Preparation of Al 2 o 3 / TiO 2 Nanofillers with core-shell structure: nano-Al with α-phase 2 o 3 As the core, butyl titanate (TBOT, C 16 h 36 o 4 Ti) is a precursor, absolute ethanol is a solvent, and glacial acetic acid is a chelating agent to generate TiO 2 Shell. Al 2 o 3 / TiO 2 The schematic diagram of the preparation structure of the core-shell nanofiller is as follows: figure 1 shown. The specific steps are:

[0070] 1) Weigh 1g of α-phase nano-Al with a diameter of 30nm 2 o 3 , through a three-roll mill three times. Add 25 mL of absolute ethanol. 2 g of polyvinylpyrrolidone (PVP) was added to the solution as a binder, and stirred evenly with a glass rod; 1 ml of butyl titanate was added, and stirred slowly...

Embodiment 2

[0087] The embodiment of this application provides the test and dispersion test of the vacuum DC surface flashover voltage of the epoxy composite insulating part, and the specific preparation method is as follows:

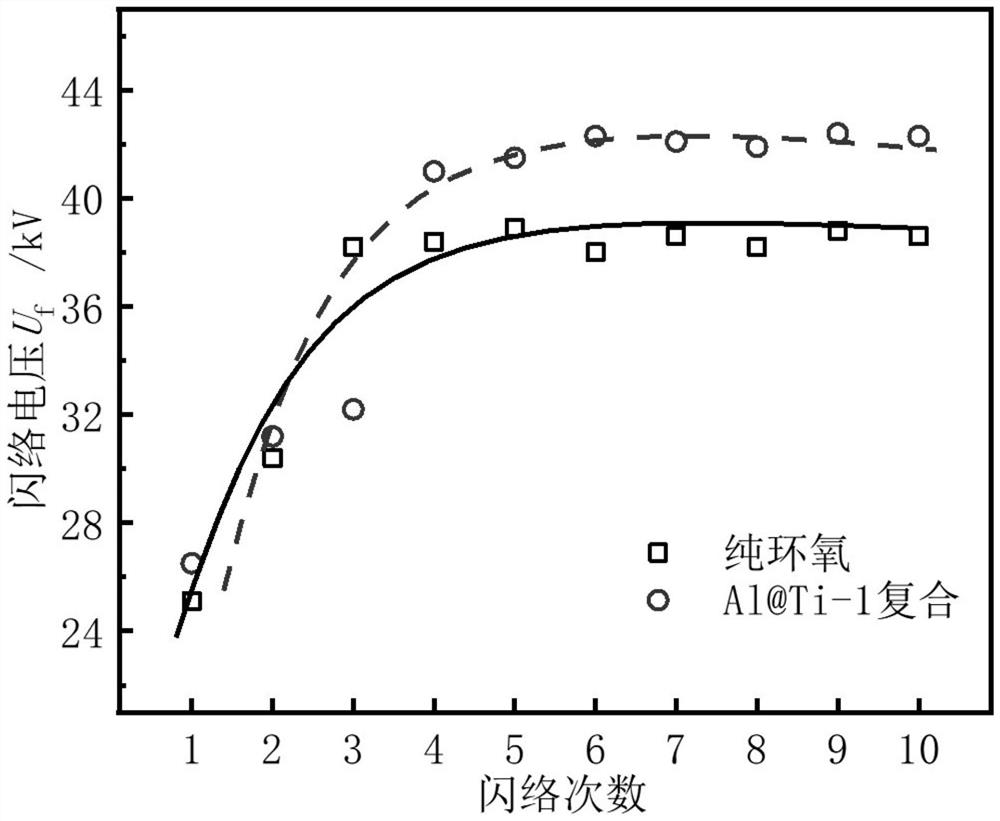

[0088] Doped with 1wt% Al in Example 1 2 o 3 / TiO 2 Epoxy composite insulating parts with core-shell structure nanofillers (core Al 2 o 3 , shell TiO 2 ) and bisphenol A type WSR618 E-51 liquid epoxy resin according to the sample that embodiment 1 makes carries out the direct current along the surface flashover voltage test under the vacuum respectively, every kind of sample carries out ten flashovers to observe the surface flashover voltage The law of change. The result is as image 3 As shown, it can be seen that after the initial flash phenomenon, the average surface flashover voltage (41.9kV) of the composite sample (marked as Al@Ti-1 composite in the figure) is higher than that of the pure epoxy sample (marked as pure Epoxy) (38.6kV), that is, the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com