A water supply tank with self-cleaning function

A water supply tank and self-cleaning technology, applied in the water supply main pipeline, water supply pipeline system, cleaning hollow objects, etc., can solve the problems of high water consumption, inconvenient replacement of filter element and filter plate, affecting experience, etc., to improve cleaning and maintenance. Efficiency and the effect of reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

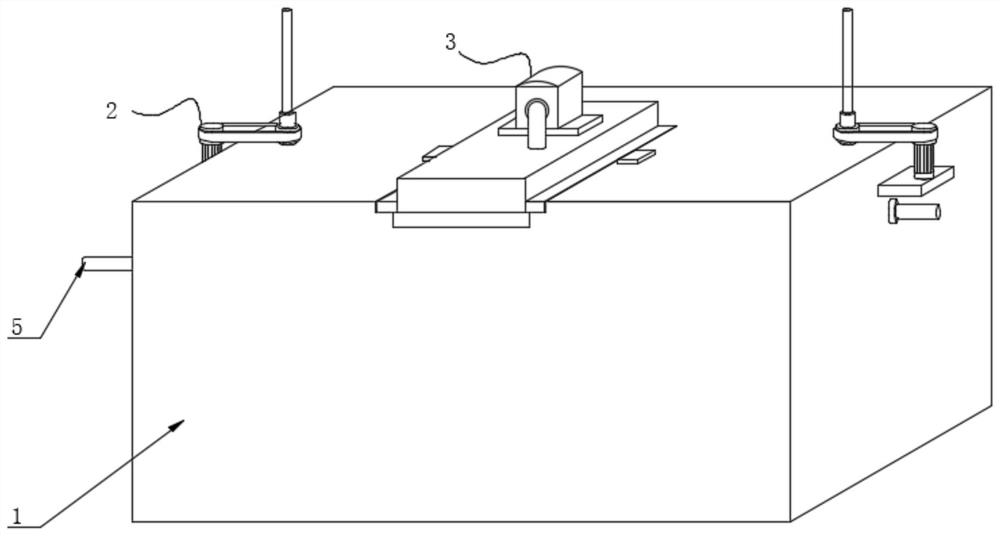

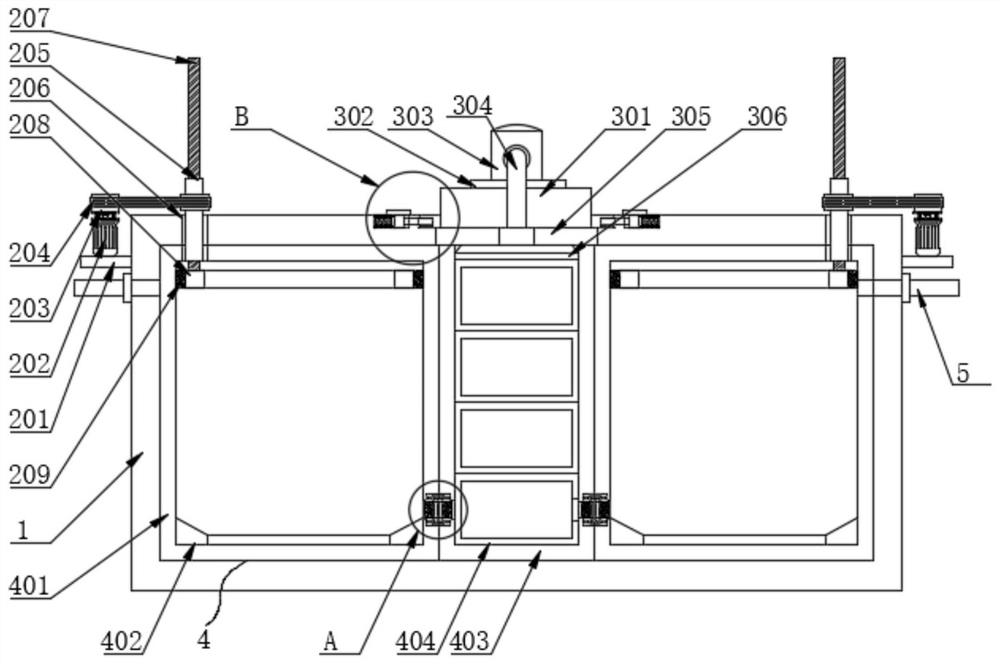

[0026] see Figure 1-6 , the present invention provides a technical solution: a water supply tank with self-cleaning function, including a water tank body 1, a filter mechanism 3 slidingly connected to the top of the water tank body 1, a water storage mechanism 4 in the inner cavity of the water tank body 1, and a water tank body 1 There are cleaning mechanisms 2 on both sides of the body;

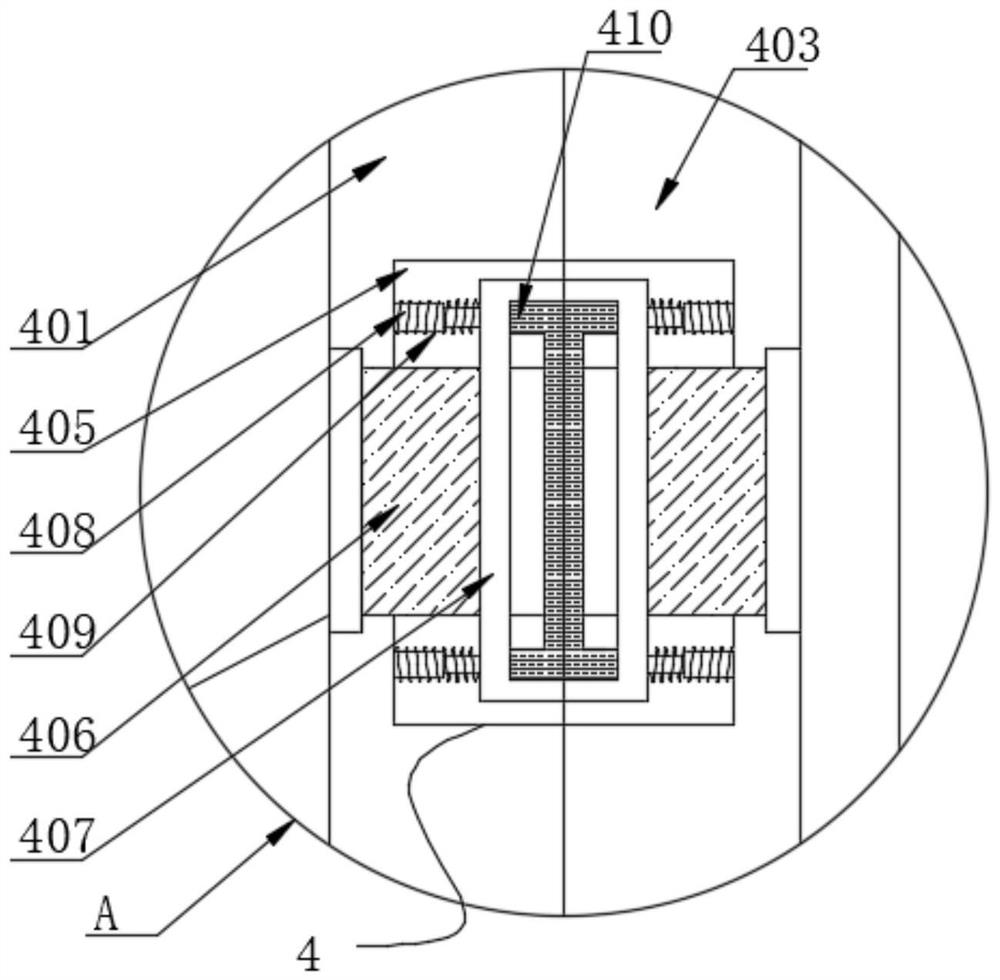

[0027] The water storage mechanism 4 includes two water diversion tanks 401 and a movable seat 403, the two sides of the movable seat 403 are respectively attached to the opposite surfaces of the two water diversion tanks 401, the inner cavity of the movable seat 403 is placed with a filter holder 404, and the inner cavity of the movable seat 403 Both sides and one side of the water diversion tank 401 are connected with a telescopic tube 406, and the other end of the telescopic tube 406 is connected with a limit seat 407, and the limit seat 407 is located in the groove 405 provided on both...

Embodiment 2

[0030] refer to Figure 7-8, the filter mechanism 3 includes a water pump 303, the bottom of the water pump 303 is fixedly connected with a mounting plate 302, the bottom of the mounting plate 302 is fixedly connected with a mounting seat 301, both sides of the mounting seat 301 are fixedly connected with a block 307, and one side of the block 307 is provided with a card The hole 308 is connected with a sliding rod 309 in the clamping hole 308, the outer wall of the sliding rod 309 is slidably connected with a sliding sleeve 310, one end of the sliding rod 309 is fixedly connected with a slider 311, and the corresponding positions on both sides of the top of the water tank body 1 are provided with chute 312, the slider 311 is slidably connected in the chute 312, the sliding sleeve 310 is embedded on one side of the slider 311, the side of the slider 311 is fixedly connected with the first spring 312, and the other end of the first spring 312 is connected to the inner cavity of ...

Embodiment 3

[0033] On the basis of Embodiment 1, the cleaning mechanism 2 includes a scraper 208, the scraper 208 is slidably connected to the inner cavity of the water separator 401, the top side of the scraper 208 is fixedly connected with a threaded post 207, and the outer wall of the threaded post 207 is threaded with a Threaded cylinder 205, the outer wall of the threaded cylinder 205 is provided with a bearing 206, and the bearing 206 is embedded in the water tank body 1 and the side of the water diversion tank 401, the outer wall of the threaded cylinder 205 is provided with a driven wheel, and the driven wheel is driven by a belt 204 Connected with a drive wheel 203, the bottom of the drive wheel 203 is fixedly connected with a motor 202, and the motor 202 is arranged on one side of the water tank body 1, and the outer wall of the scraper 208 is fixedly connected with a brushing brush 209, and the brushing brush 209 is connected with the water tank The inner cavities of 401 are fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com