Burr cleaning method for chamfering position of plastic bottle forming die

A technology for forming molds and cleaning methods, which is applied in the direction of manufacturing tools, accessories of toolholders, and tools for lathes, etc., can solve problems such as manual deburring, achieve the effects of reducing labor intensity, ensuring cleaning effects, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Install the chamfering knife and forming mold on the CNC machine tool, so that the forming mold is located directly below the chamfering knife;

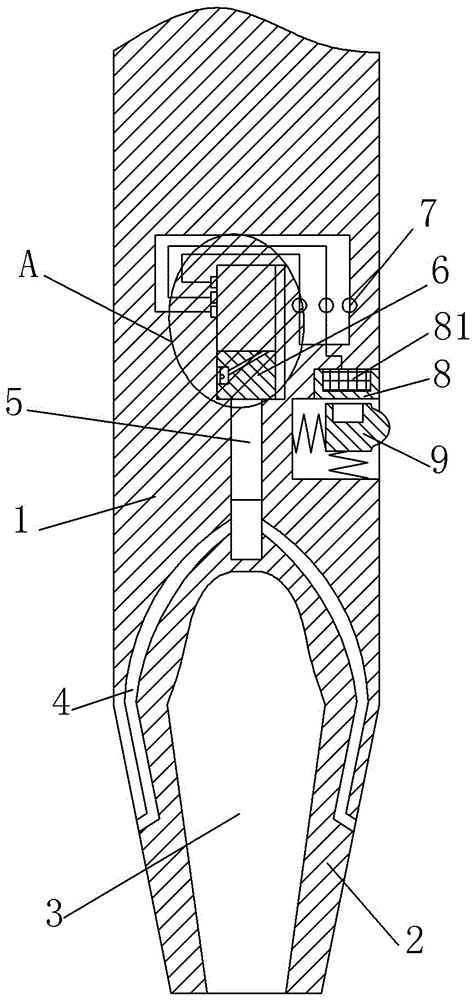

[0029] (2) Start the CNC machine tool. While driving the chamfering knife to rotate at a speed of 200r / min, the CNC machine tool drives the chamfering knife to move downward at a speed of 0.5cm / s. The chamfering knife moves downward while rotating to form The mold is chamfered. At this time, a large amount of heat will be generated on the cutting edge 2. The heat enters the air inlet hole and enters the piston cavity along the vent hole 4. The heat entering the piston cavity will act on the piston tail 5, the piston The tail part 5 will move upwards along the piston cavity under the action of the heat, and the piston tail part 5 will drive the piston head 6 to move upwards along the working chamber while moving upwards along the piston cavity;

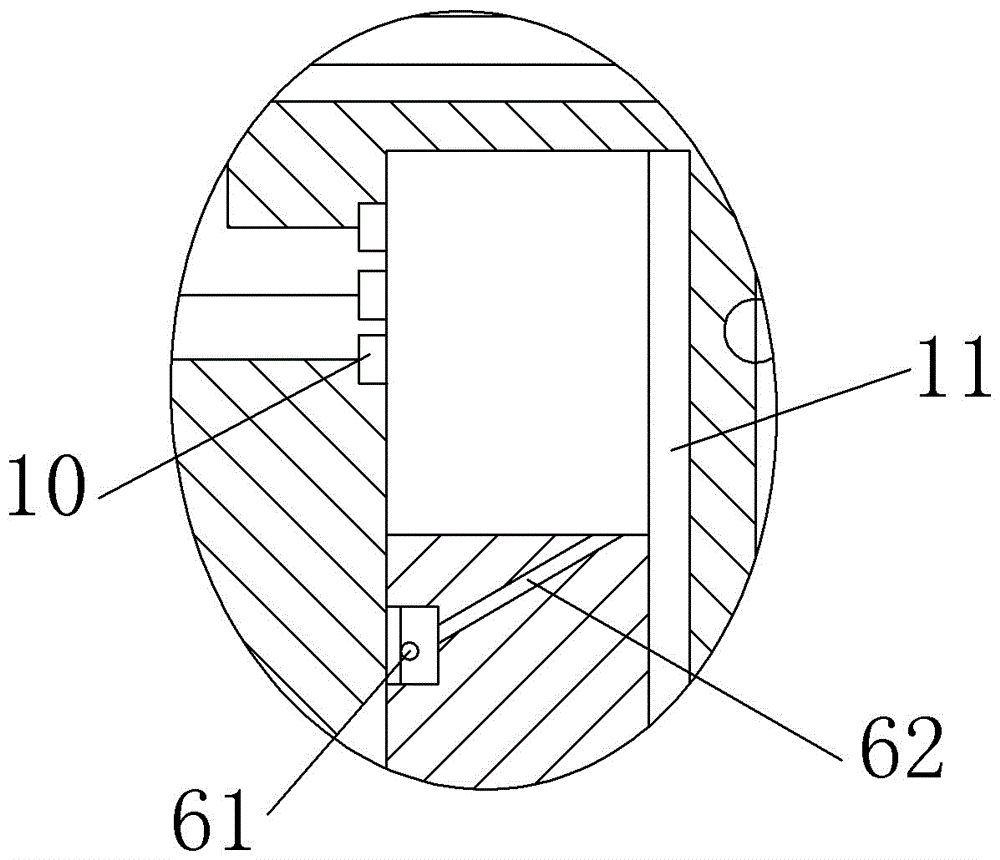

[0030] (4) Turn on the light source 61 at the installation hole. When the chamfe...

Embodiment 2

[0032] The difference between embodiment 2 and embodiment 1 is that in step (2), the rotating speed of the chamfering knife is 250r / min, and the speed of the downward movement of the chamfering knife is 1.5cm / s.

Embodiment 3

[0034] The difference between embodiment 3 and embodiment 1 is that in step (2), the rotating speed of the chamfering knife is 300r / min, and the downward moving speed of the chamfering knife is 3cm / s.

[0035] The chamfering knife used in each of the above-mentioned embodiments includes a chamfering knife body 1, on which two mounting parts are arranged, each mounting part is provided with a cutting edge 2, and a cutting edge 2 is arranged on each mounting part, A flute 3 is provided between the blades 2 .

[0036] Each cutting edge 2 is provided with an air intake hole, a piston chamber is provided on the upper side of the chip removal groove 3, and a vent hole 4 is respectively opened on both sides of the piston chamber, and one side of the vent hole 4 communicates with the piston chamber , the other side of the ventilation hole 4 communicates with the carrying hole, and a working chamber is also arranged on the upper side of the piston chamber, and a lens 11 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com