Novel steel ball slide rail type sliding door with damping structure

A steel ball slide rail type, sliding door technology, applied in the mechanical field, to achieve the effect of reducing blocking feeling, reasonable design, smooth and fast movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

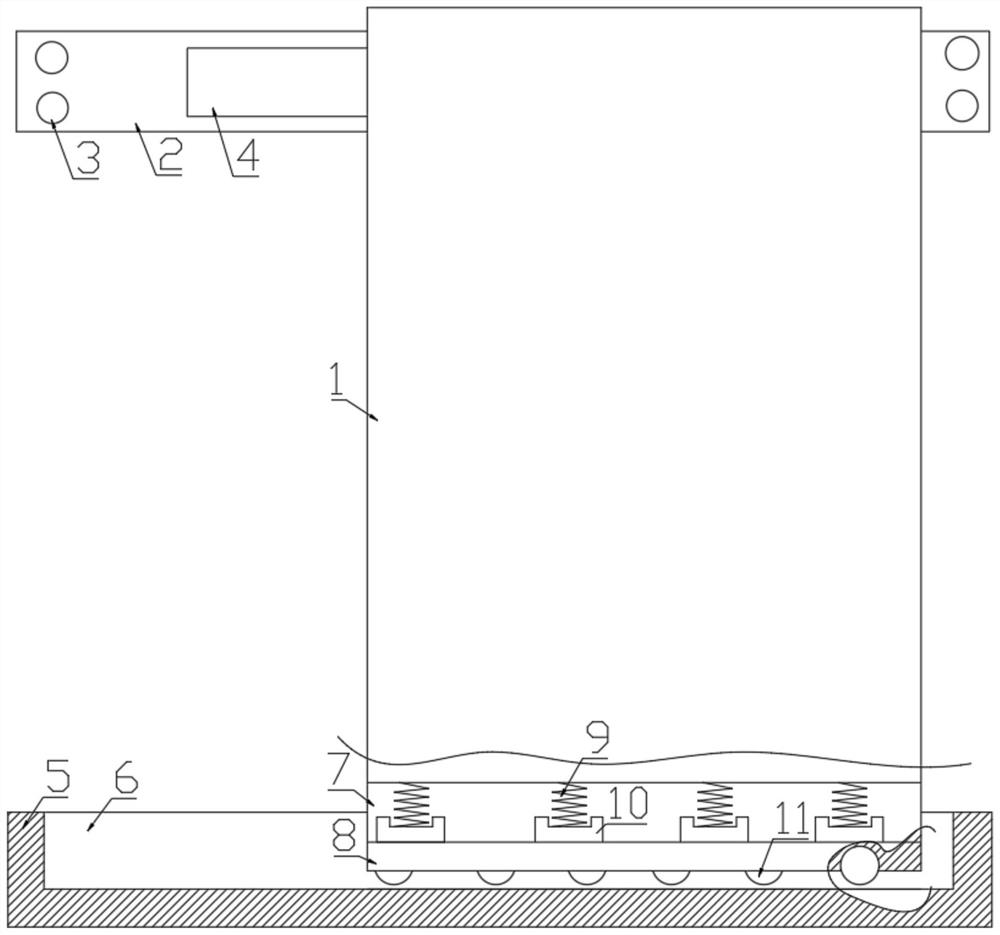

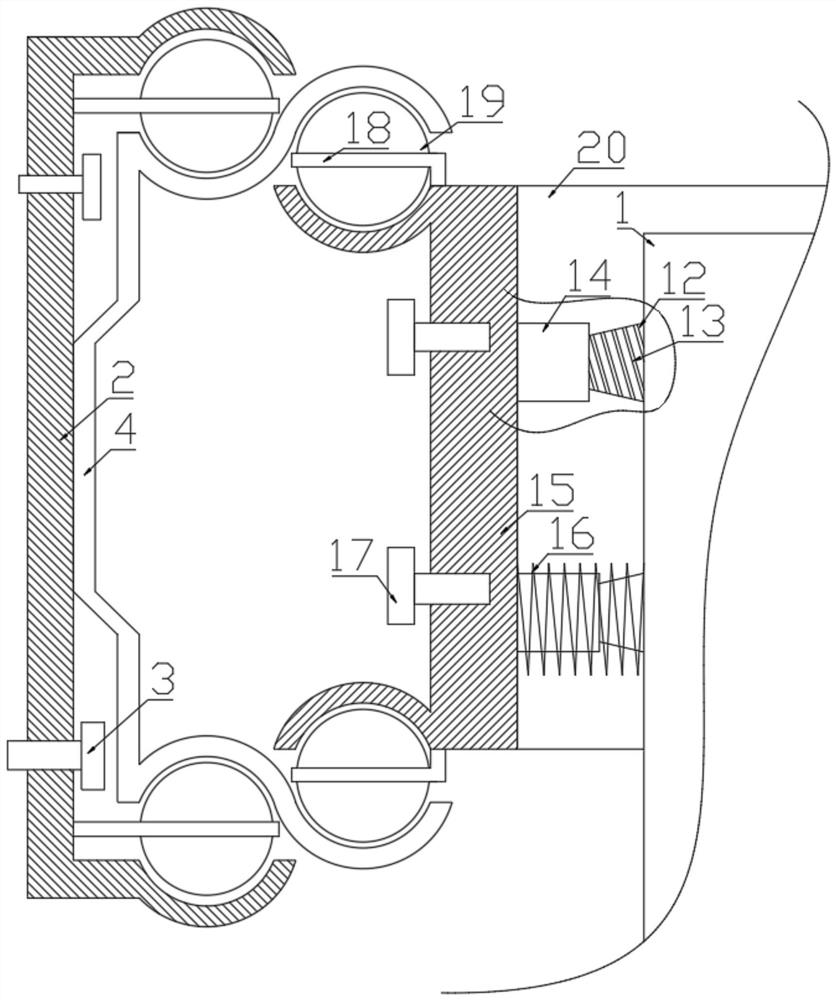

[0020] Example 1: Please refer to Figure 1~3 , in the embodiment of the present invention, a new type of steel ball slide rail type sliding door with a shock absorbing structure, including a door panel 1, a device plate 20 is provided on the upper end of the door panel 1 and a mounting block 14 is provided inside the device plate 20, and the mounting block 14 is internally fitted A tapered rod 12 is installed and the other end of the tapered rod 12 is slidably mounted on the door panel 1, an inner fixed rail 15 is arranged on the outside of the device plate 20 and an intermediate fixed rail 4 is arranged on the outside of the inner fixed rail 15, and an intermediate fixed rail 4 is arranged on the outside of the intermediate fixed rail 4. The outer fixed rail 2 and the outer fixed rail 2 and the middle fixed rail 4 and the middle fixed rail 4 and the inner fixed rail 15 are equipped with steel balls 19, and the lower side of the door panel 1 is equipped with a buffer plate 8 a...

Embodiment 2

[0021] Embodiment 2: The invention also provides another embodiment, which is improved on the basis of the above-mentioned embodiment. A buffer cavity 7 is provided on the underside of the door panel 1 and a fixed bottom of the buffer cavity 7 is fixed. Seat 10, the upper side of fixed seat 10 is provided with spring a9 and the upper end of spring a9 is connected to door panel 1, and when door panel 1 is vibrated, the vibration is buffered by buffer plate 8 and then transmitted to spring a9 to buffer and stabilize, so that door panel 1 remains Move smoothly.

[0022] The working principle of the present invention: install and fix the outer fixing rail 2 barrel lid screw a3 on the fixed object, then install and fix the inner fixing rail 15 barrel lid screw b17 on the device plate 20, and install the steel ball 19 and the middle fixing rail 4 together Between the inner fixed rail 15 and the outer fixed rail 2, when the door panel 1 needs to be pushed, the door panel 1 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com