Metal tube bending fatigue test device and method capable of controlling stress on line

A technology for controlling stress and testing equipment, which is applied in the direction of measuring equipment, using repeated force/pulsation force to test the strength of materials, instruments, etc., which can solve the problems of unable to automatically implement constant stress value and high equipment life, so as to reduce bending stress , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

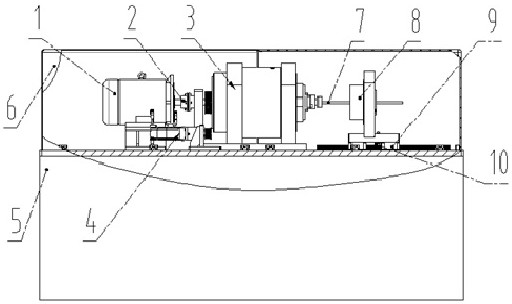

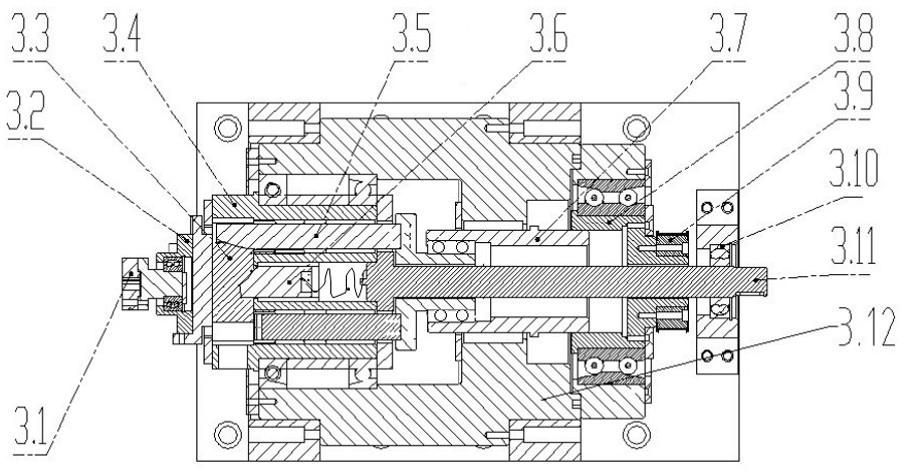

[0024] Combine below figure 1 and figure 2 The specific implementation of the metal pipe bending fatigue test device capable of controlling the magnitude of stress on-line according to the present invention will be further described.

[0025] Such as figure 1 and figure 2 Shown is the invented metal pipe bending fatigue test device that can control the stress on-line. The drive motor 1 is fixedly installed on the left side of the platform plate on the frame 5, and the output shaft end is connected with the drive shaft 3.11 through the coupling 2; the drive shaft 3.11 The middle part is supported by an auxiliary support seat 3.10, and the end is connected with the internal rotating head 3.4 of the drive eccentric part 3, so that the output end mechanism can perform high-speed rotational movement with the motor 1; a servo motor 4 is placed laterally on the central axis, and is installed and fixed on 5 on the frame platform plate is synchronously connected with the synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com