Temperature-regulating cigarette filter tip and preparation method thereof

A cigarette and filter technology, which is applied in the field of cigarette filters, can solve problems such as low smoking feeling, uneven core material release, and inability to further realize the taste of smoking smoke, so as to achieve the effect of improving the smoking taste and good smoking experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation step A of the water-carrying capsule, preparing the water-containing capsule core and putting a certain amount of deionized water into the dropper;

[0034] The deionized water in step B and step A is added dropwise to the molten wall material at 80°C, and the temperature is lowered to obtain a water-carrying capsule (referred to as A).

Embodiment 2

[0036] Preparation steps of water-carrying capsules 1. Put the capsule wall material into the glue tank, heat to 60-90°C, stir until the material is fully dissolved, keep warm and degas to form glue;

[0037] Step 2: Using a co-extrusion device with a coaxial multi-layer dropper, the glue and capsule core material are dropped into the condensation medium through the coaxial multi-layer dropper to form a spherical capsule. The dripping temperature of the glue solution is 85°C. The temperature of the condensing medium is 10° C. to obtain a water-carrying capsule (marked as B).

Embodiment 3

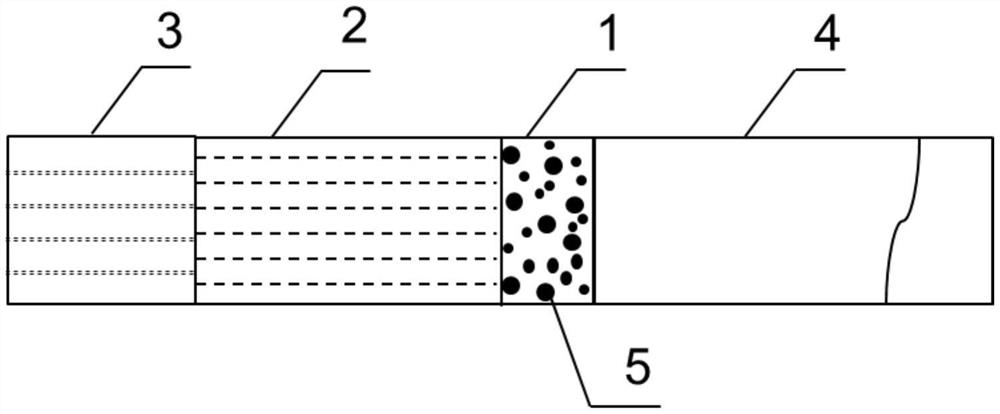

[0039] Preparation of temperature-regulated cigarette filter

[0040] Get the water-carrying capsule that obtains among the embodiment 1-2, fill in the temperature-regulating cigarette filter tip, filter tip is divided into three sections, and middle section is filter section, utilizes acetate fiber to make; Capsule section, the filling quantity of water-carrying capsule is 5mg (under the same filling quantity, embodiment 1, 2 are respectively marked as A1, B1), 10mg (under the same filling quantity, embodiment 1, 2 are respectively marked as A2, B2) ; The other end of the filter section is a water-absorbing fiber, and the water-absorbing fiber is made of a water-absorbing resin commonly used in this field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com