Tobacco sheet and tobacco product

A tobacco sheet, tobacco technology, applied in the direction of tobacco, processing tobacco, manufacturing cigars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 90g of 50% edible alcohol was added to 10g of ripe tobacco safflower fruit extract in Yunnan for dilution, and the obtained dilution was evenly sprayed on 2 kg of tobacco flakes. It is sealed and placed at room temperature for 24 hours, put into an oven, and dried at 40° C. until the moisture content of the sheet is 13%, and rolled into cigarettes by conventional methods. The cigarettes were conditioned for 48 hours in an environment with a temperature of (22±1)°C and a relative humidity of (60±2)%, and were taken out and smoked by a cigarette evaluation group.

Embodiment 2

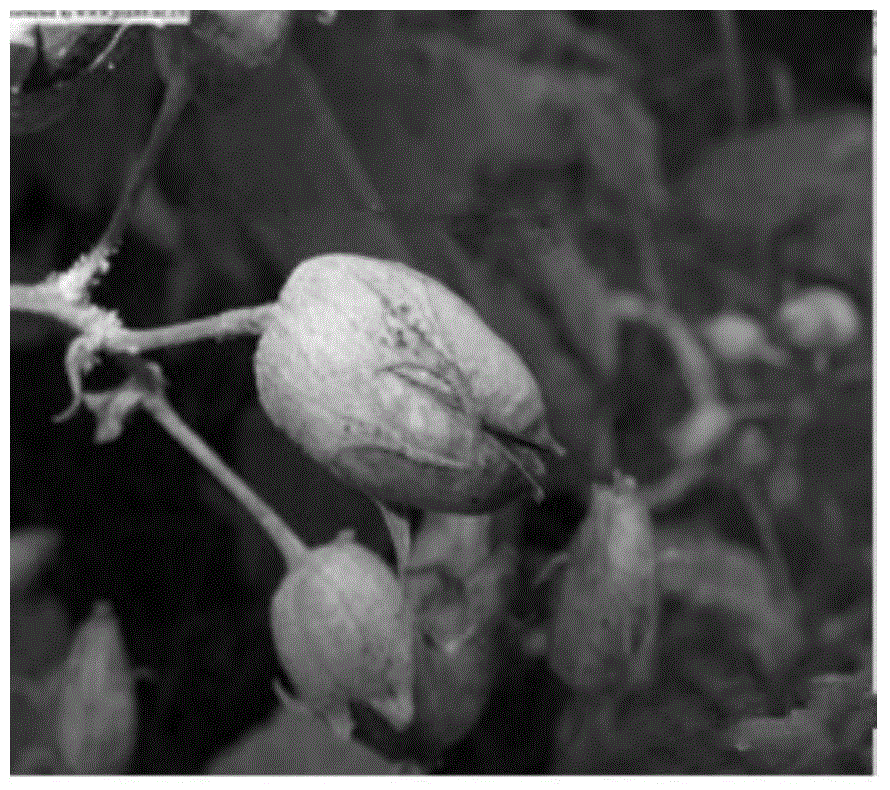

[0046]Except that 10 g of mature Nicotiana safflower fruit extract from Yunnan was replaced by 10 g of soon-to-mature Nicotiana safflower fruit extract from Yunnan, the same method as in Example 1 was followed.

[0047] Compared with the cigarette of the blank control example, the cigarette of Example 2 has significantly reduced smoke miscellaneous gas, significantly reduced irritation, significantly increased smoke concentration and smoke agglomeration, significantly improved smoking taste, and has a light fragrance. And in harmony with the aroma of cigarettes.

Embodiment 3

[0049] In addition to replacing 10 g of the mature Nicotiana safflower fruit extract from Yunnan with 10 g of the soon-to-mature Nicotiana safflower fruit extract from Yunnan, and roasting it at 105 ° C before obtaining the extract, the other procedures were as follows: The same method of embodiment 1 is operated.

[0050] The results show that, compared with the blank control example, the cigarette smoke of Example 3 has significantly reduced miscellaneous gas, significantly reduced irritation, significantly increased smoke concentration and smoke agglomeration, significantly improved smoking taste, enhanced aroma of flue-cured tobacco, and Harmonizes with smoke.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com