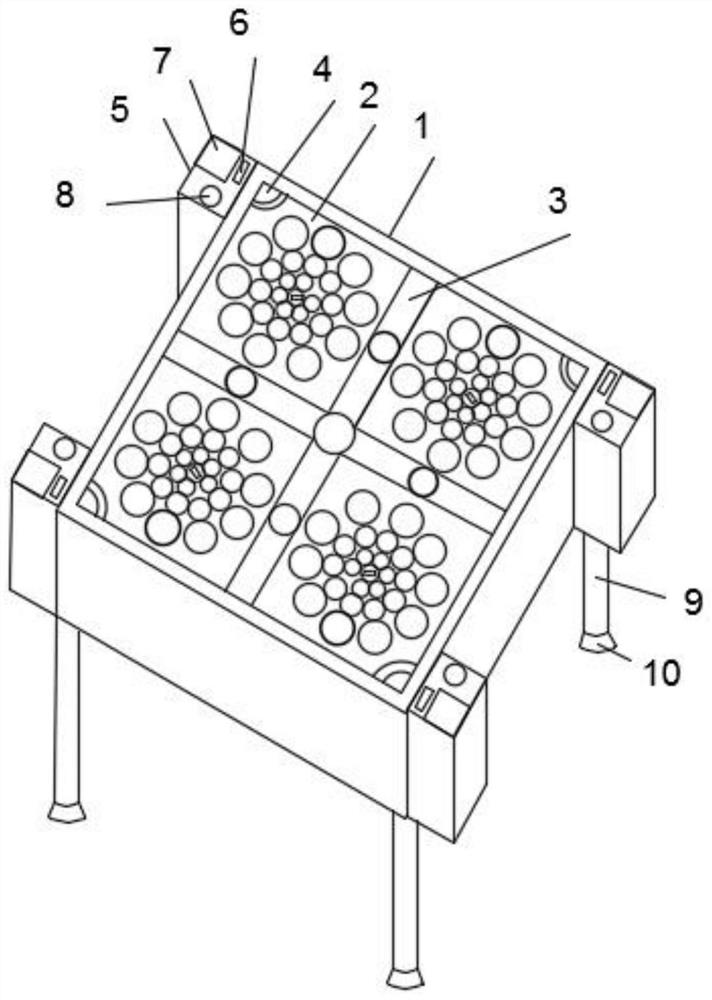

Test tube water bath heating equipment for laboratory

A water bath heating technology used in laboratories, applied in water bath/sand bath/air bath, etc., can solve the problems of inability to heat test tubes in water baths, achieve good fixing effect, accurate detection temperature, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

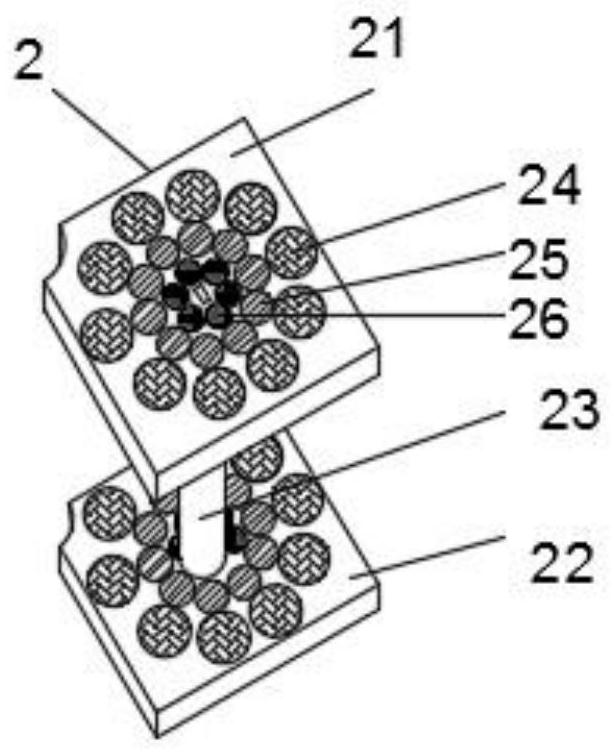

[0042] Working condition 1: heating test tubes with multiple temperature conditions

[0043] Step 1: Add water to the inside of the water bath box body 1, and put the test tubes at the same temperature in the order of large, medium and small into the large positioning hole 24, the medium positioning hole 25 and the small positioning hole of the fixed upper plate 21 In 26, rotate the lifting rod 23 to adjust the distance between the fixed upper plate 21 and the fixed lower plate 22, so that the bottom of the test tube is put into another group of large positioning holes 24, medium positioning holes 25 and small positioning holes of the fixed lower plate 22. No. locating hole 26;

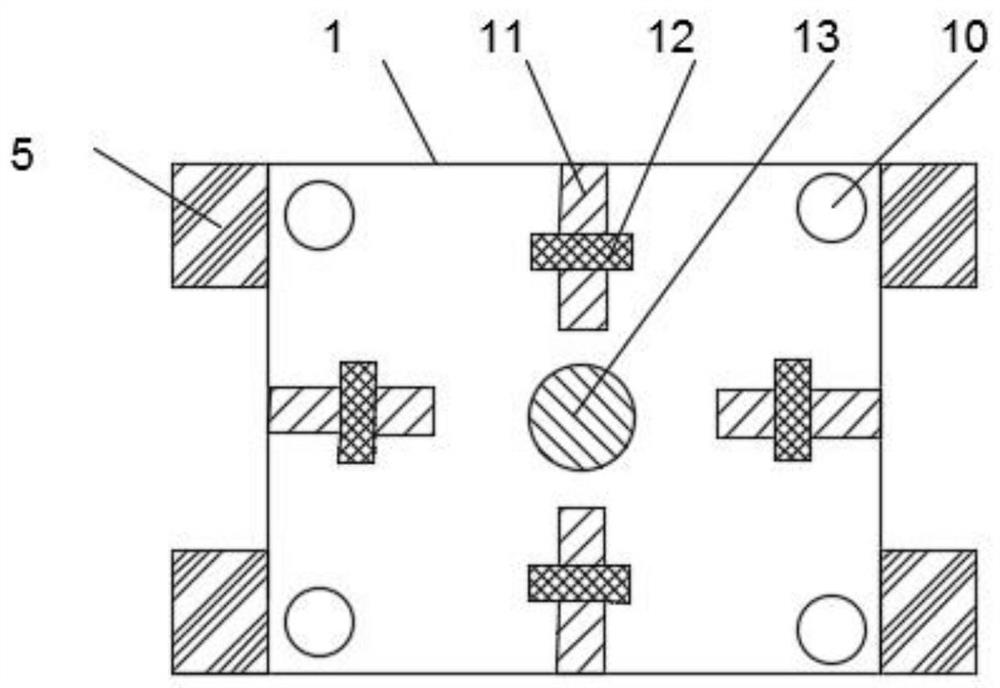

[0044] Step 2: Place a number of fixing mechanisms 2 in different areas divided by the separation mechanism 3 into equal parts of the water bath tank body 1, turn on the switch button 6, and send instructions to the AVR control processor by turning the adjustment knob 8 to adjust the heating rod 4, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap