Clutch pressing plate clamp

A clutch and pressure plate clamping technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problems that the clutch pressure plate cannot be accurately clamped and fixed, the processing accuracy is low, and the operation is troublesome, so as to achieve convenient and simple clamping and improve processing efficiency. , Improve the effect of product processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

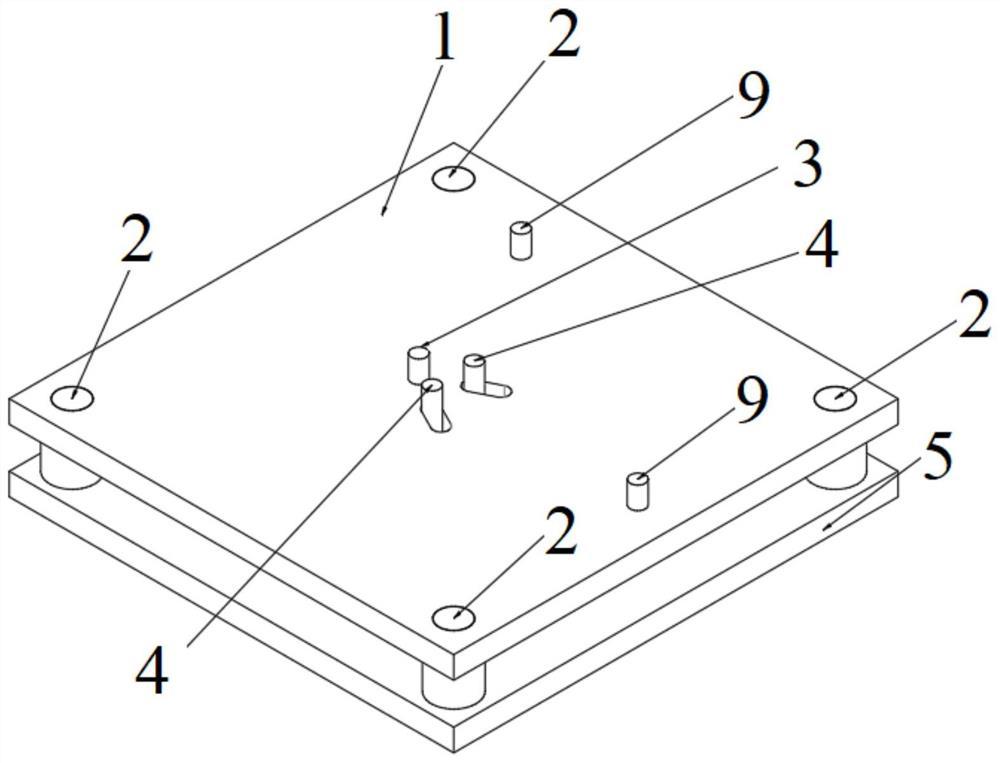

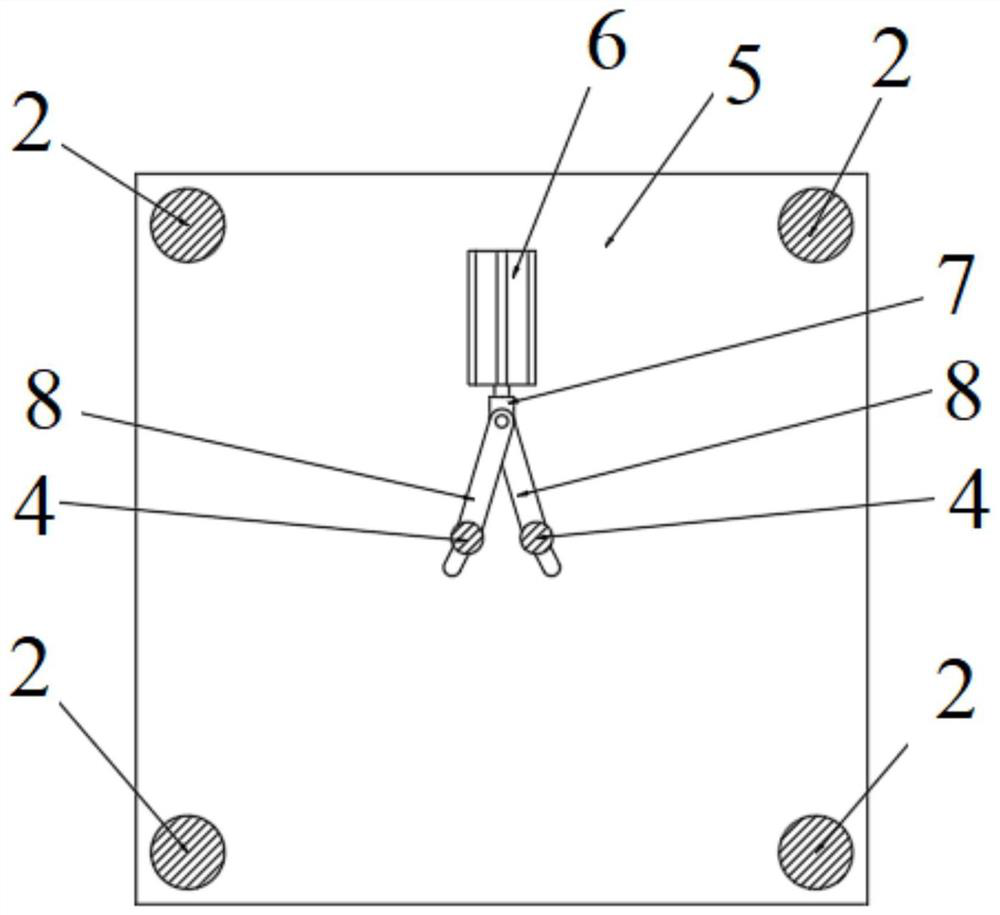

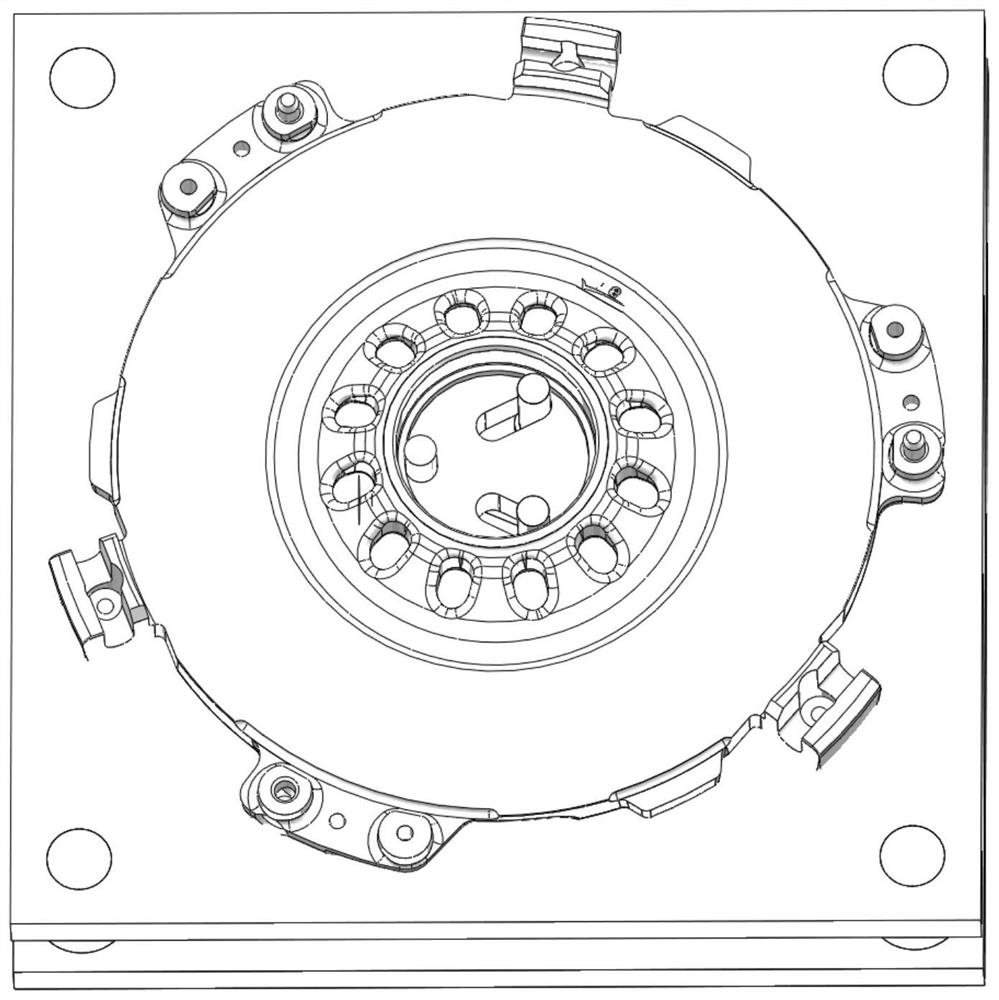

[0015] Such as Figure 1 to Figure 3 As shown, the present invention provides a clutch pressure plate clamp, including a fixed plate 5, a backing plate 1 arranged on the fixed plate 5, a first positioning pin 3 arranged on the backing plate 1 and used for positioning the clutch pressure plate and The second positioning pin 9, the two fixed columns 4 for applying the pressing force to the clutch pressure plate to fix it, and the drive that is arranged between the fixed plate 5 and the backing plate 1 and is used to control the movement of the two fixed columns 4 Mechanism, the backing plate 1 has ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap