Assembly device and assembly method of a disc-type multi-station poultry water dispenser

An assembly device and multi-station technology, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of high work intensity and low efficiency, and achieve the effect of improving the degree of automation and stable and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

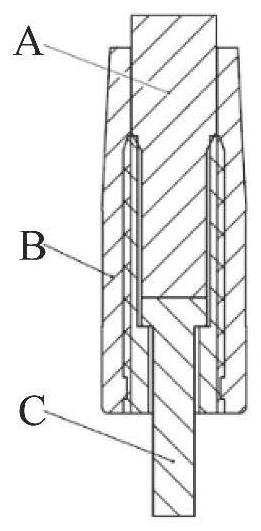

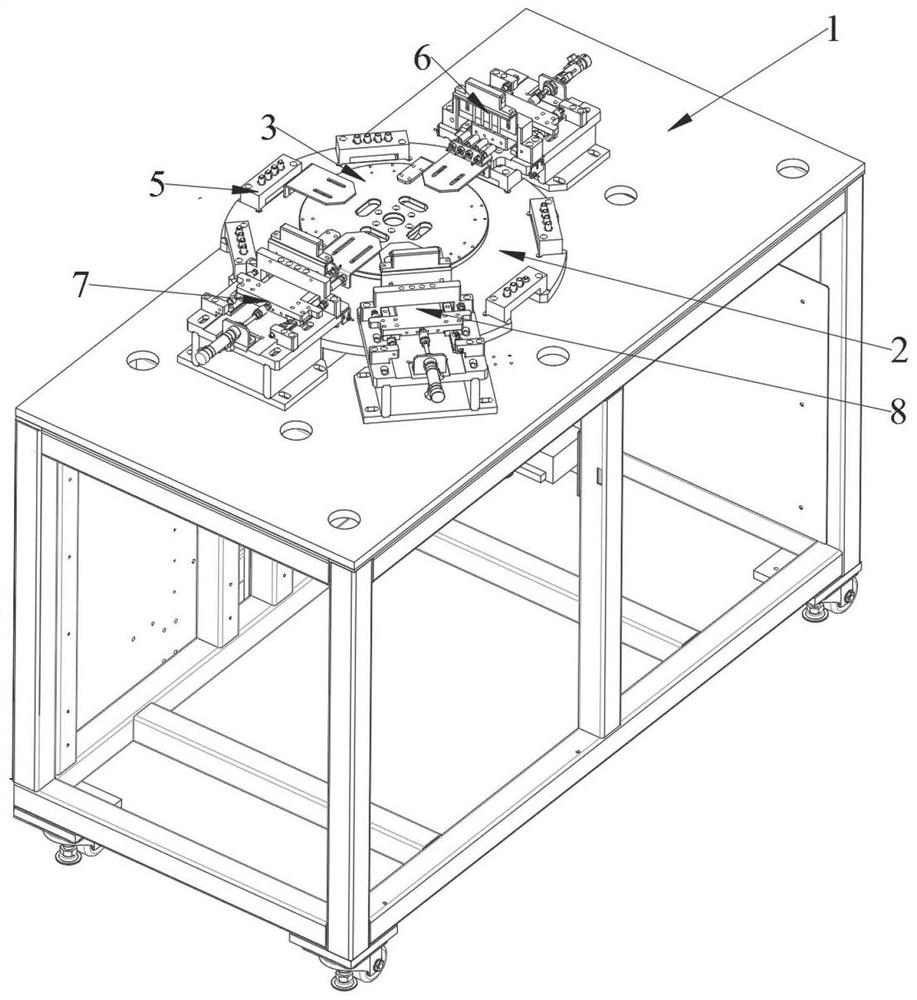

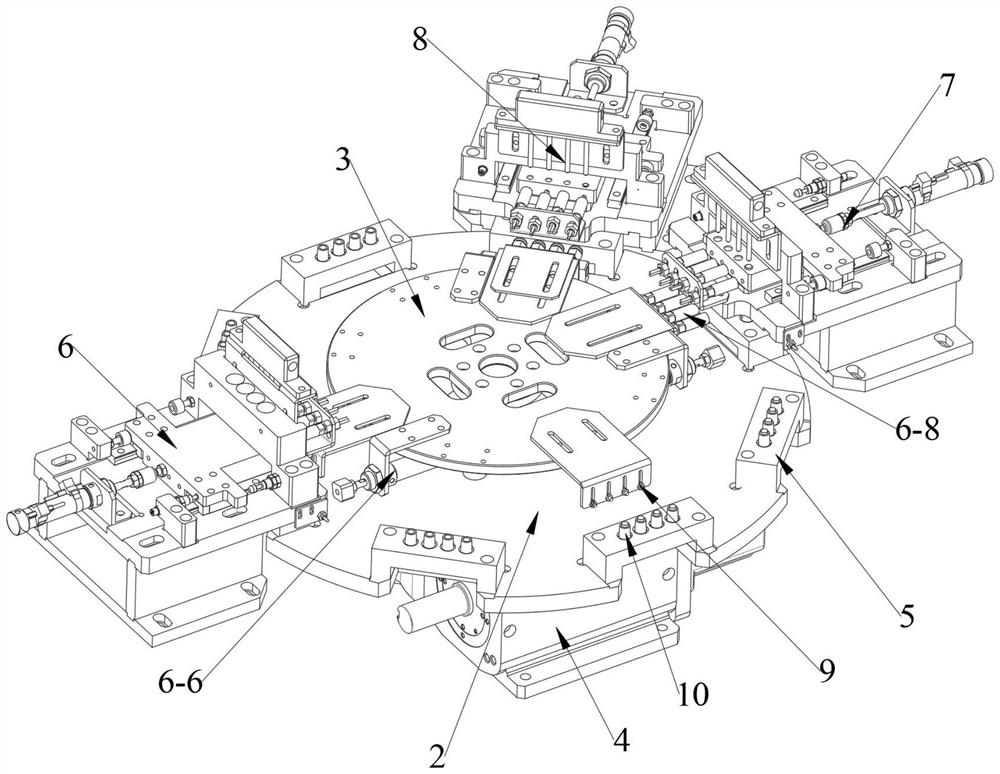

[0033] as Figure 2 and 3 As shown, a disc-type multi-station poultry drinking fountain assembly device, including rack 1 station switching plate 2, center fixed plate 3, switching drive element 4, material mounting block 5, plastic parts installation mechanism 6, large valve stem installation mechanism 7, small valve stem installation mechanism 8 and unloading detection components. Switching drive element 4 uses a motor and a reducer. Station switching plate 2 is supported in the middle of rack 1; switching drive element 4 is mounted on rack 1, and the rotary output shaft is fixed with the station switching plate 2, and the drive station switching plate 2 rotates and locates. The center fixing disc 3 is coaxially set above the station switching disc 2; the bottom of the central fixing disc 3 is fixed with a fixed column. The retention column passes through the center hole of the station switching disc 2 and is fixed to rack 1. The eight material mounting blocks 5 are all installed...

Embodiment 2

[0049] The difference between the present embodiment and Example 1 is:

[0050] Plastic parts mounting mechanism 6, large stem mounting mechanism 7, small stem mounting mechanism 8 on the feed block 6-4 feed hole 6-4-1 can be disassembled and installed with material cache tube. The bottom end of the material buffer tube communicates with the feed hole 6-4-1. The inner diameter of the boging tube is slightly larger than the diameter of the material being conveyed, and there is no situation where the two materials are side by side. Plastic parts installation mechanism 6 of the four material cache tubes placed in a sequential stacked arrangement of plastic parts; large stem installation mechanism 7 of the four material cache tubes placed in a sequentially stacked arrangement of large stems; small stem installation mechanism 8 of the four material cache tubes placed in turn stacked small stem;

[0051] Since the feed hole on the feed block, the material transition hole on the slide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com