Printer paper outlet structure and printer

A paper outlet, printer technology, applied in printing devices, printing and other directions, can solve the problems of electronic devices damage, entry, easy to be splashed by water, etc., to achieve the effect of increasing reliability, increasing waterproof performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

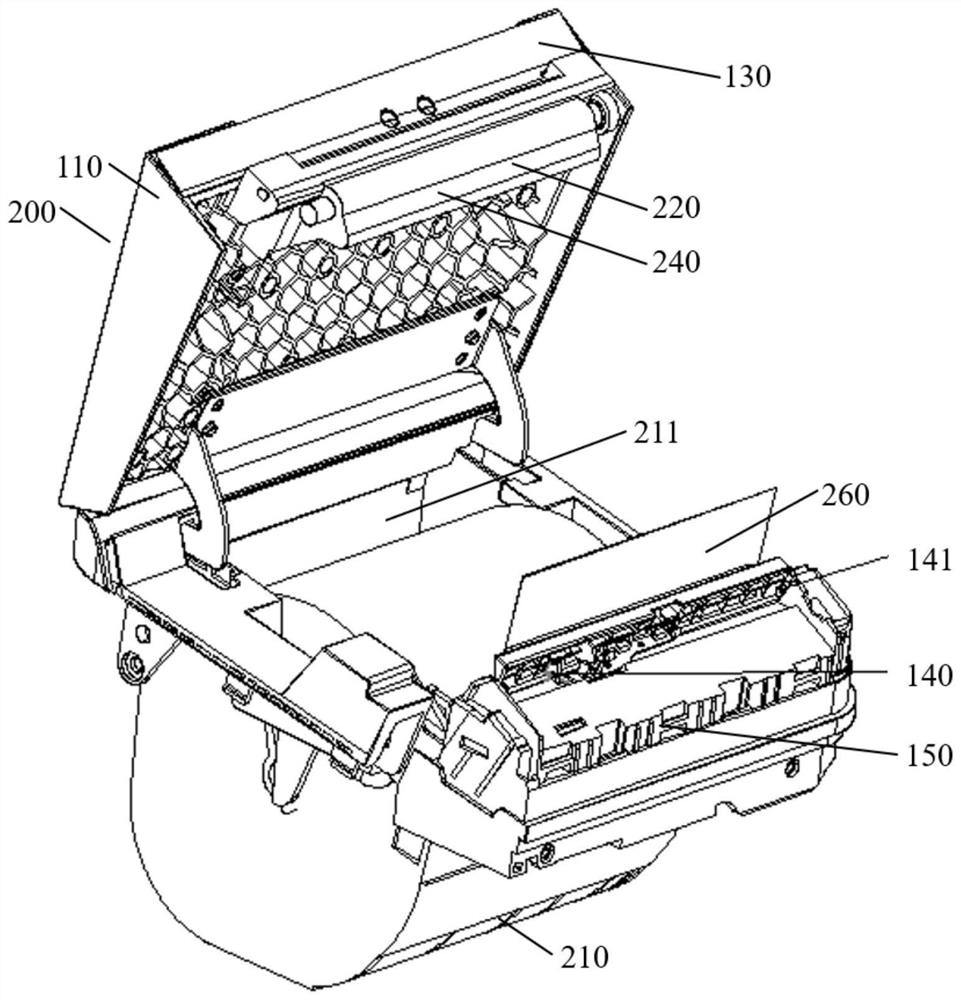

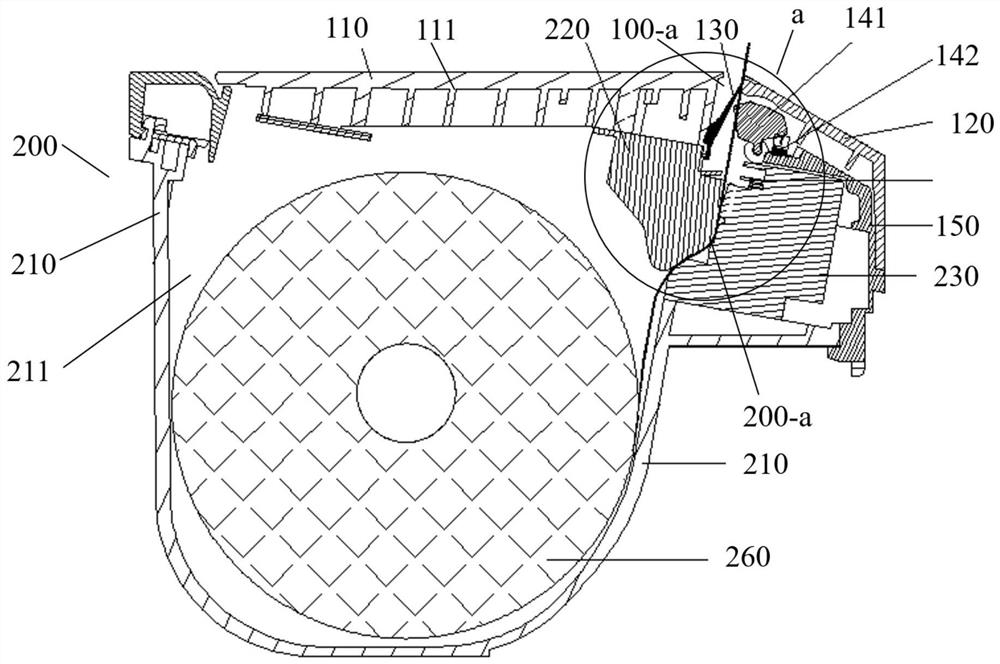

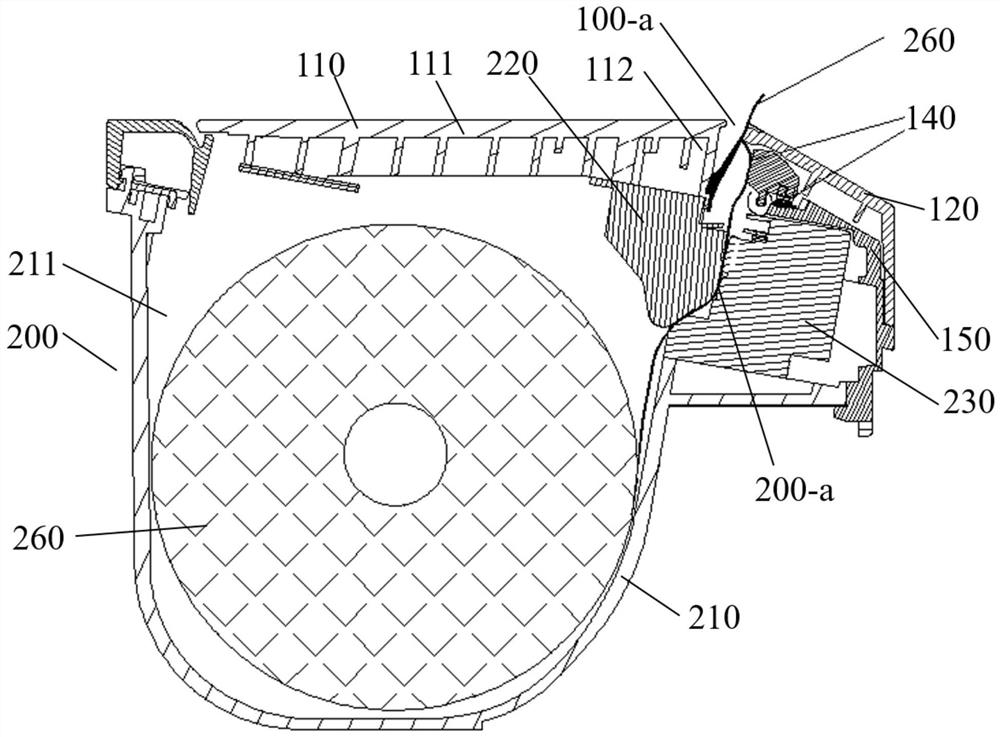

[0053] This embodiment is a printer paper outlet structure 100, such as Figure 1 to Figure 4 As shown, the paper outlet structure 100 of the printer includes: a first cover 110 , a second cover 120 , a waterproof strip 130 and an alarm device 140 .

[0054] Specifically, the first machine cover 110 and the second machine cover 120 can be installed outside the printer 200, and the first machine cover 110 and the second machine cover 120 are connected to each other, leaving a gap outside the connection to form the paper outlet 100 -a. The waterproof strip 130 and the alarm device 140 are installed inside the paper outlet 100-a.

[0055] Further, the first cover 110 includes a first cover main body 111 and a waterproof strip fixing part 112, the side of the first cover main body 111 close to the second cover 120 extends in the opposite direction along the paper output direction, forming a waterproof strip fixing part 112. In the drawings of this embodiment, the outside of the...

Embodiment 2

[0071] This embodiment is a printer 200, such as Figure 1 to Figure 5 As shown, the printer 200 includes a paper bin 210, a first printer head 220, a second printer head 230, and the printer paper outlet structure 100 of the first embodiment. It should be noted that the drawings of this embodiment include the printer paper outlet structure 100 of the first embodiment and other structures, so the drawings of this embodiment can be used to explain the solution of the first embodiment. The same parts of this embodiment and Embodiment 1 will not be repeated here.

[0072] Specifically, such as Figure 5 As shown, the inside of the paper bin 210 has a printing paper storage chamber 211, and the opening edge of the printing paper storage chamber 211 is hingedly connected to the end of the first cover main body 111 away from the waterproof strip fixing part 112. The first printer head 220 is mounted on the waterproof strip fixing part 112. part 112 inside. That is, the first cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com