Operation control method and device of electric carrier

An electric pallet truck, operation control technology, applied in the directions of transportation and packaging, motor vehicles, trolleys, etc., can solve the problems of easy misoperation, unconfirmed signals, hidden safety hazards, etc., to achieve the effect of easy strength and prevention of false start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

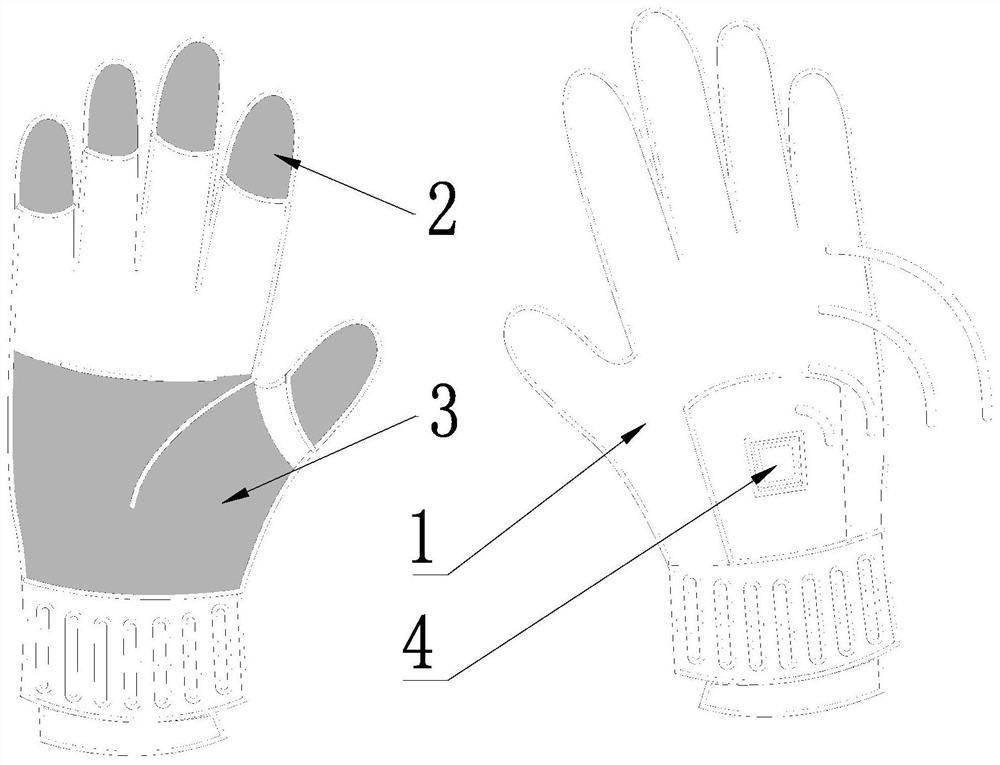

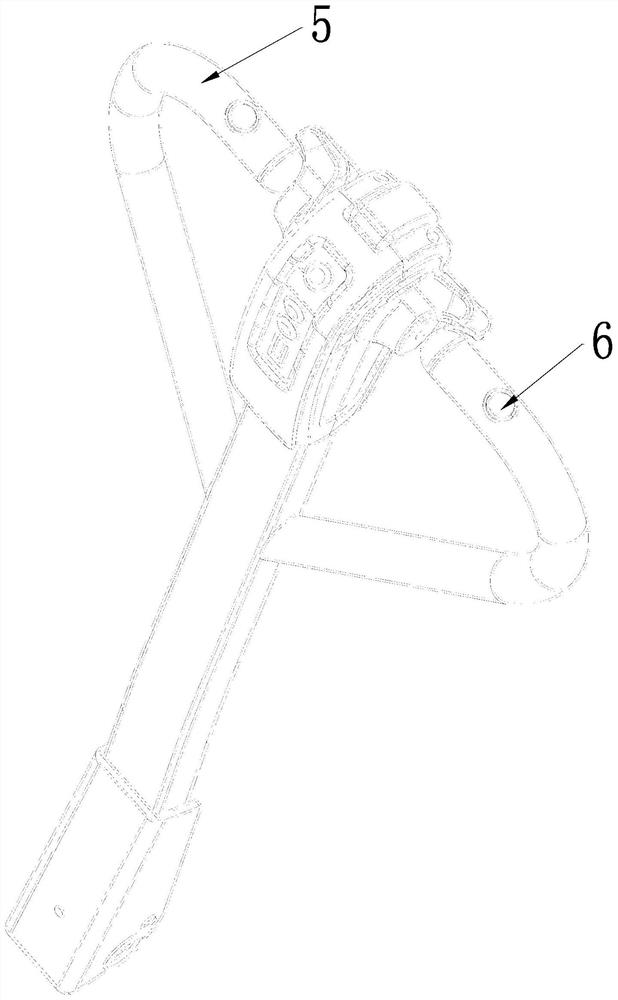

[0021] Such as Figure 1-2 As shown, this embodiment relates to an operation control method of an electric pallet truck, including the following steps:

[0022] S1. The user holds the joystick 5 through the wearable device 1. When there is no operation, the wearable device 1 has no output. The wearable device 1 does not output a signal when there is no force.

[0023] S2. The user operates the joystick 5 and pulls it backward, and the force sensor in area A 2 of the wearable device 1 outputs a negative signal; if the user presses the confirmation button 6 on the joystick 5 at the same time, the joystick 5 receives the negative signal and The electric pallet truck is controlled to move backward through the controller, otherwise the controller has no output.

[0024] Wherein, area A 2 is the finger area of the wearable device 1 . The magnitude of the negative signal is proportional to the magnitude of the signal detected by the force sensor in the wearable device 1 , and th...

Embodiment 2

[0037] Such as figure 1 As shown, an operation control device for an electric truck includes a handle, and also includes a wearable device 1. The wearable device 1 is provided with a force sensor and a first communication module. The joystick 4 is provided with a confirmation button 5. A second communication module connected to the first communication module is provided.

[0038] The force sensor is disposed on the finger part of the wearable device 1 and the palm part of the wearable device 1 .

[0039] The beneficial effects of the present invention are: the forward and backward signals are confirmed through the wearable device, the strength and direction of the hand can be detected accurately, the signal confirmation is better processed, and the strength is easier to control; and then confirmed by the confirmation button, Prevent the electric pallet truck from starting by mistake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com