Hand-pressing cloth clamping mop

A clamping and mop technology, which is applied in the field of hand-pressed mop replacement mop cloth, can solve the problems of complex structure, multiple springs, and difficult control of force, and achieve the effect of simplifying the structure of the mop, reducing the height of the shell body, and reducing the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

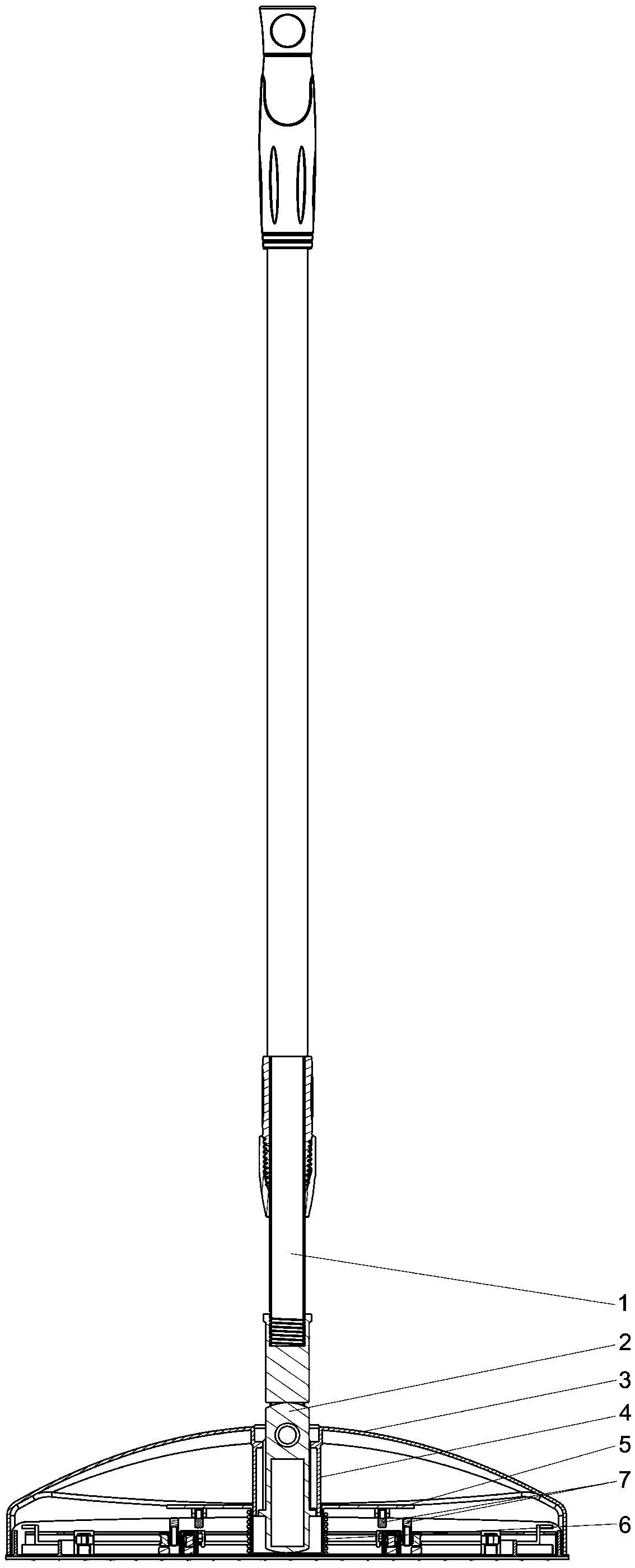

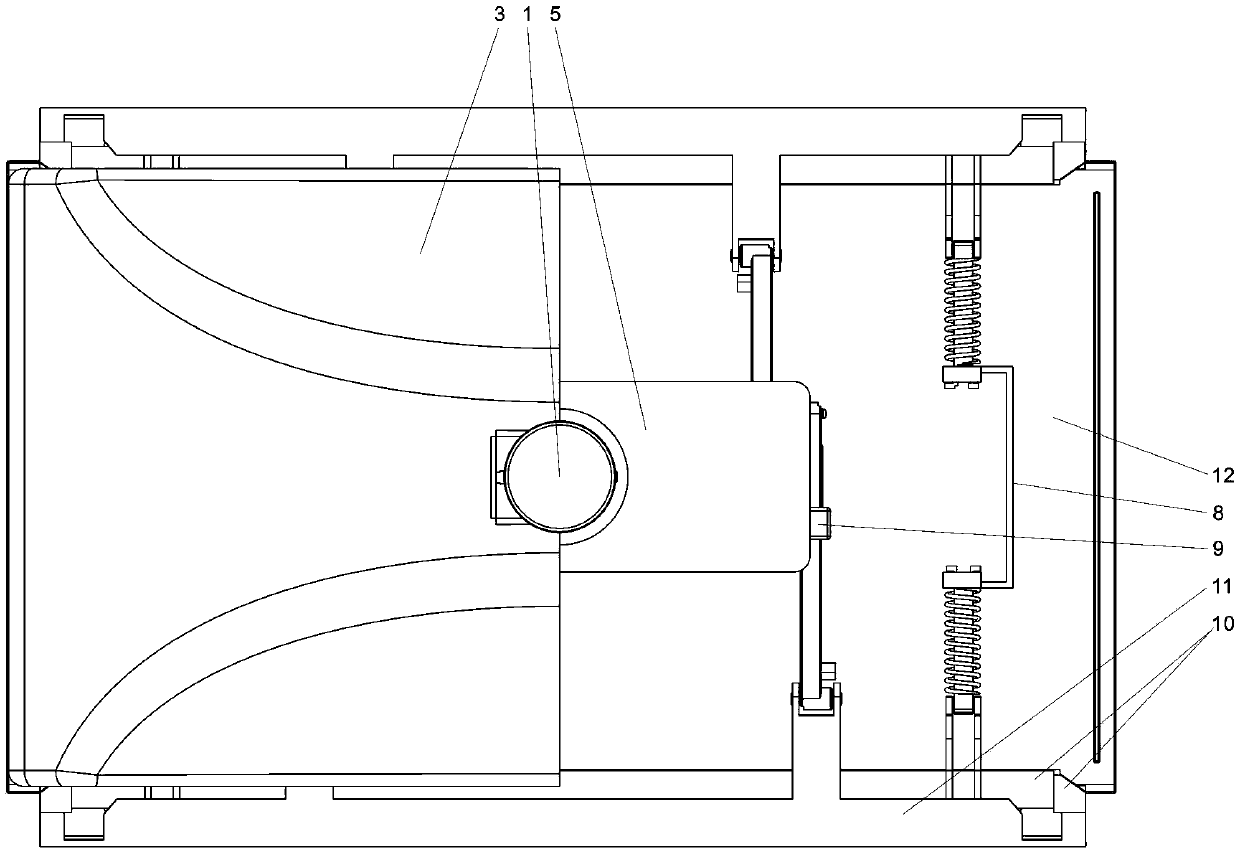

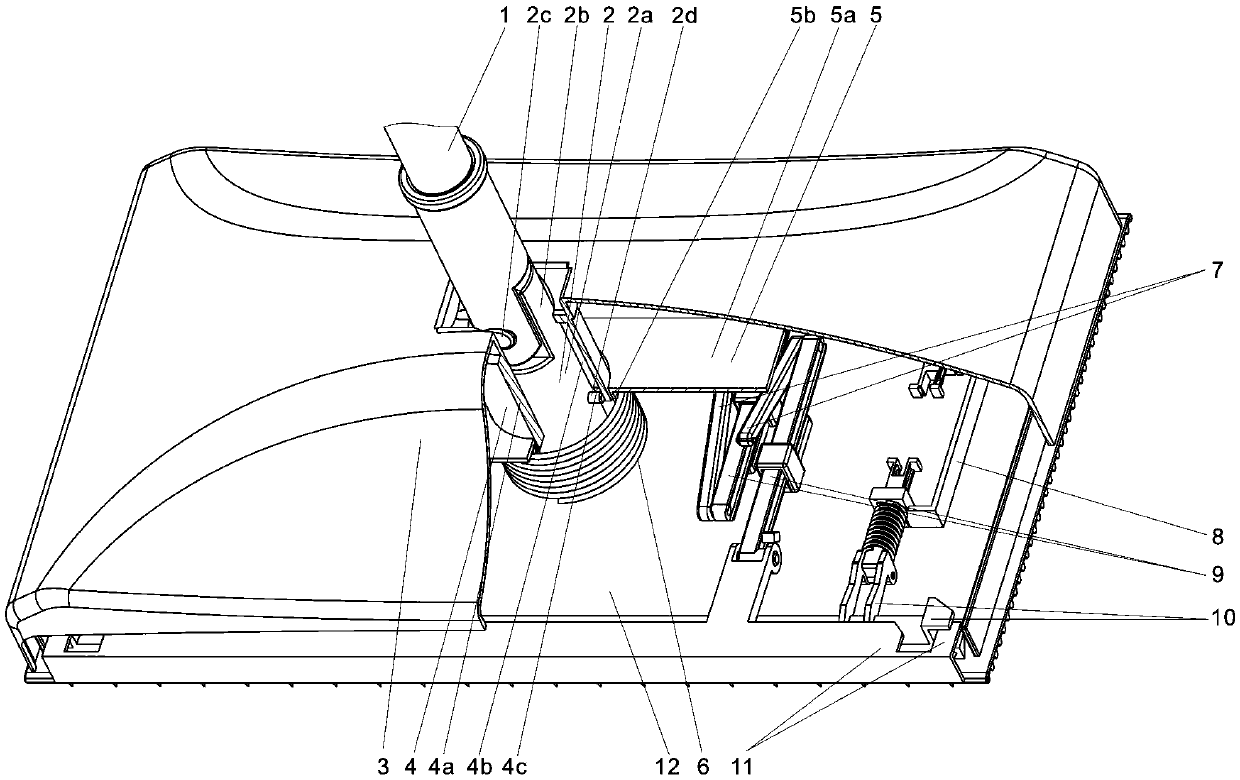

[0035] Such as Figure 1 to Figure 6 As shown, a hand-pressed cloth mop includes a mop rod 1, a movable column 2, a casing 3, a sleeve 4, a transmission plate 5, a spring 6, a connecting rod 7, an inner claw slide bar 8, an outer claw slide bar 9, Inner claw 10, outer claw 11, base plate 12, up and down positioning device.

[0036] Described mop bar 1 is similar to existing mop bar, and its lower end has a U-shaped hinge with a hole.

[0037] The housing 3 is a cover with a lower opening. The bottom plate 12 is a rectangular plate body, the upper end is connected with the casing, and the lower end surface is used for laminating the mop cloth. The outer claws 11 are used for hooking the mop. The outer claw slide bar 9 is slidably connected with the base plate 12, and can slide forward and backward. One end is hinged with the outer claw 11, and the other end has a pin joint. The inner claws 10 cooperate with the outer claws 11 to form a pair of clamping parts, and under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com