Automobile door placing rack

A technology for car doors and material racks, which is applied in the direction of assembly vehicles, rigid containers, machine containers, etc. It can solve the problems of bumping and shaking of material racks, car door detachment, and inconvenient transportation of car doors, so as to facilitate control and realize material loading and the effect of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

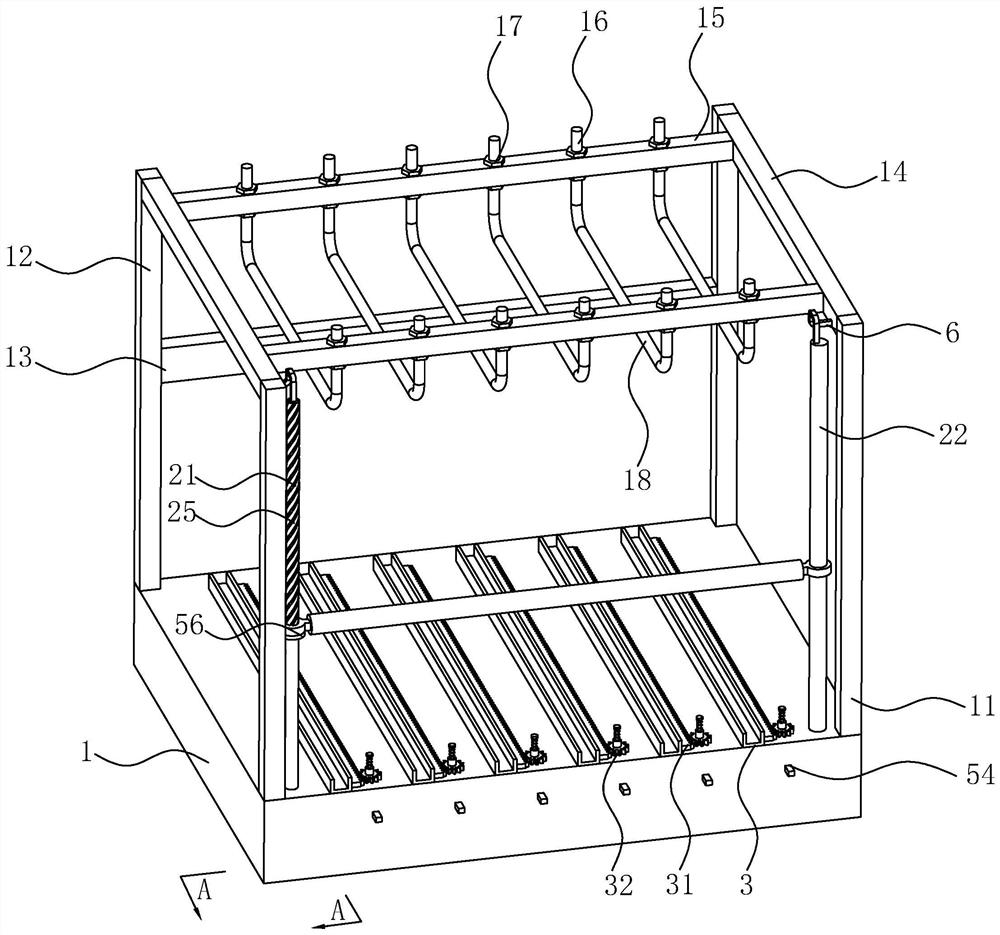

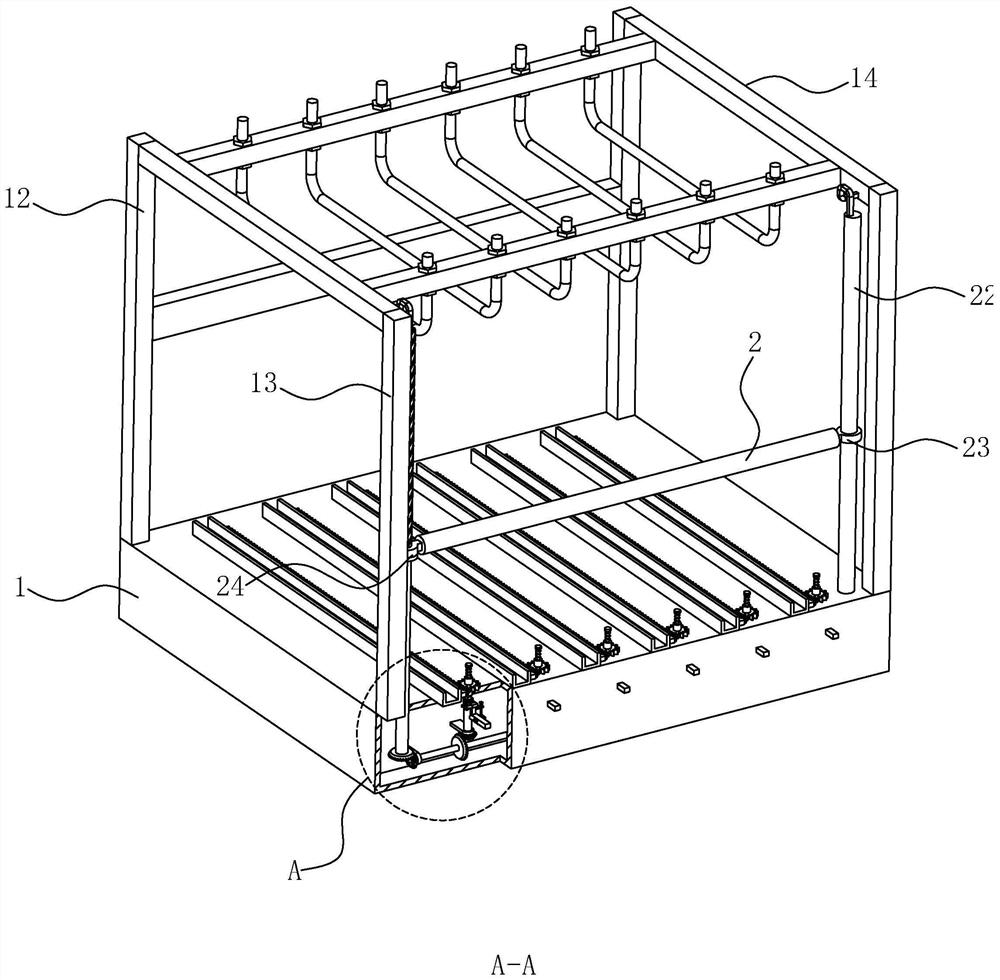

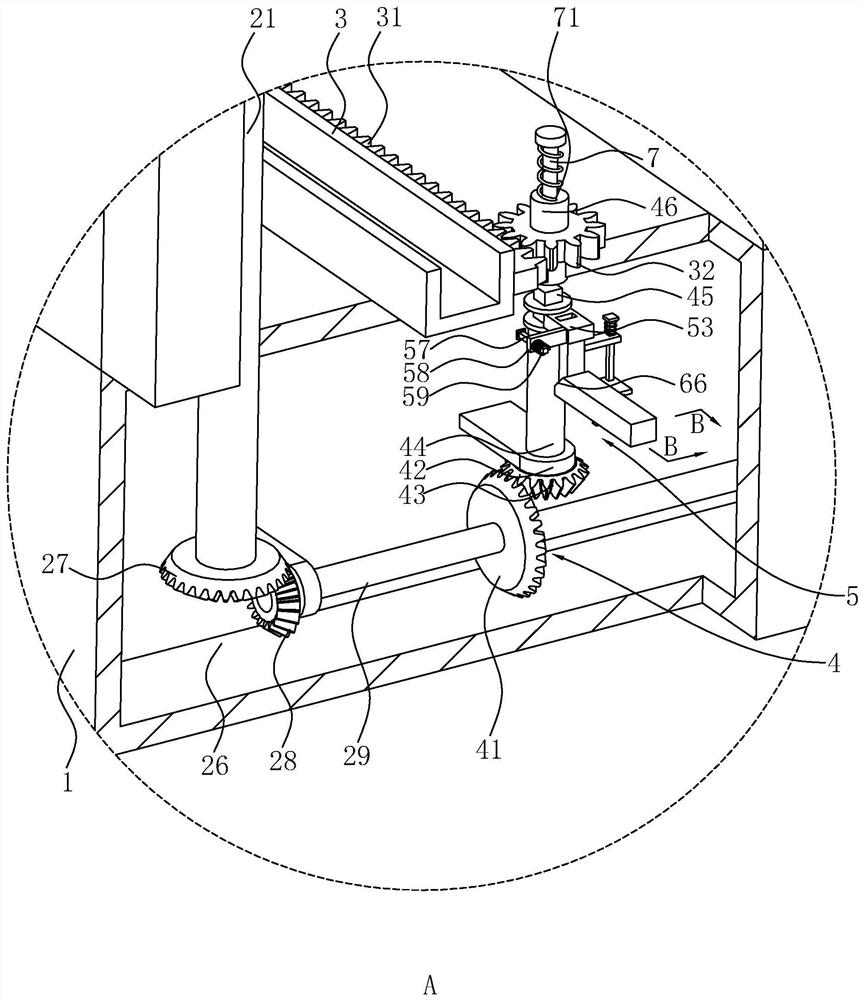

[0036] The following is attached Figure 1-4 The application is described in further detail.

[0037] The embodiment of the present application discloses a material rack for placing an automobile door. refer to figure 1 The car door placing rack includes a base 1 and two first uprights 11 and two second uprights 12 fixed on the top of the base 1 . The relative inner sides of two adjacent second columns 12 are fixed with back bars 13, and the relative inner sides of adjacent first columns 11 and second columns 12 are fixed with cross bars 14; the back bars 13 are used to block the automobile doors, thereby Limit the movement distance of the car door. Two crossbeams 15 are fixed on the opposite inner sides of the two crossbars 14; a plurality of connecting rods 16 are evenly distributed along the length direction of the crossbeam 15 on each crossbeam 15; 15 fixed connections. The bottom ends of the two connecting rods 16 are fixed with a stop rod 18 . Barbs 6 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com