Phase-change high-tear-strength rubber and preparation method thereof

A high tear strength and phase change technology, applied in the field of rubber preparation, can solve the problems of natural rubber performance decline, failure, easy tearing, etc., to achieve extended service life, effective tear protection, improved tensile strength and resistance The effect of tearing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

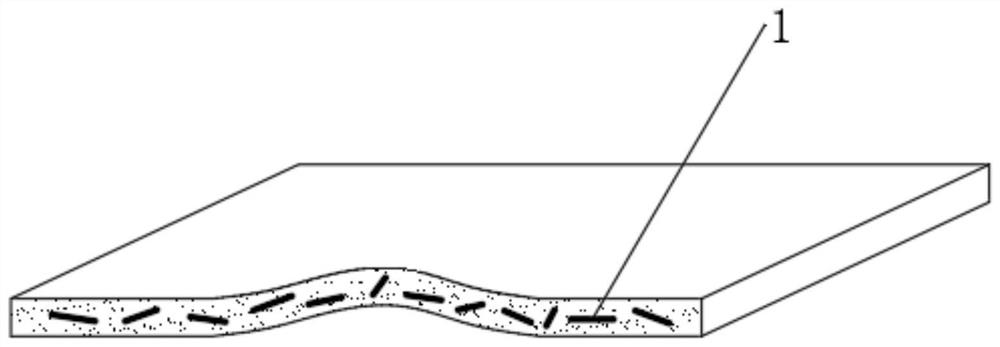

[0042] see figure 1 , a phase change type high tear strength rubber, comprising the following raw materials in parts by weight: 100 parts of natural rubber latex in dry rubber, 40 parts of styrene-butadiene rubber, 40 parts of butadiene rubber, 6 parts of zinc oxide, stearic acid 4 parts, 2 parts of rubber protective wax, 3 parts of anti-aging agent, 3 parts of vulcanizing agent, 1 part of accelerator, 30 parts of carbon black, 2 parts of polypropylene fiber, 10 parts of tear-resistant resin and 115 parts of phase change anti-overextension rod .

[0043] Antiaging agent is antiaging agent RD.

[0044] The vulcanizing agent is sulfur, and the sulfur content in the sulfur is ≥95wt%.

[0045] The accelerator is accelerator DM.

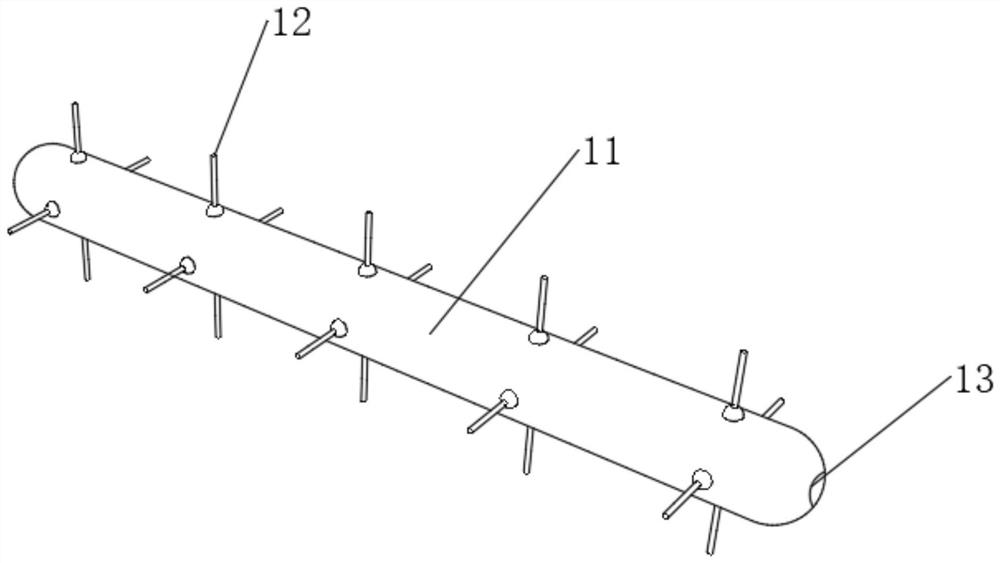

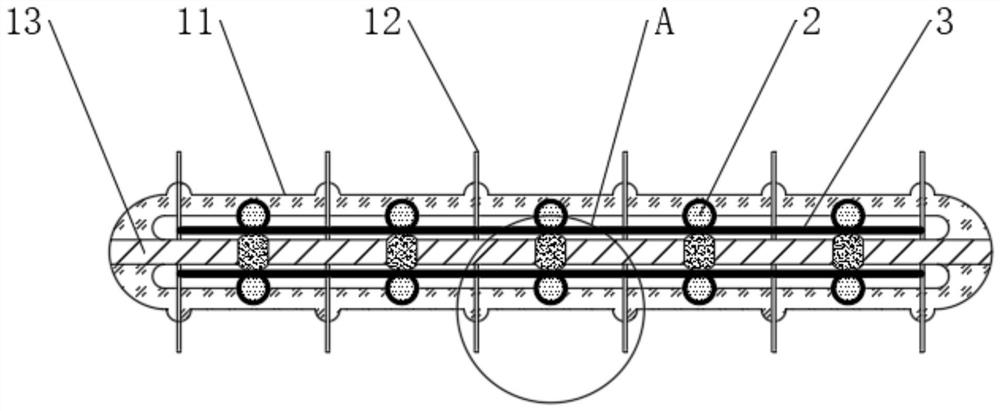

[0046] see Figure 2-3 The phase change anti-overstretching rod 1 includes an outer follower sleeve 11, a plurality of stretch sensing rods 12 and a feedback insert rod 13 embedded in the outer follower sleeve 11, and a plurality of stretch sensing ro...

Embodiment 2

[0057] A phase change type high tear strength rubber, comprising the following raw materials in parts by weight: 110 parts of natural rubber latex in dry rubber, 50 parts of styrene-butadiene rubber, 50 parts of butadiene rubber, 8 parts of zinc oxide, 6 parts of stearic acid 3 parts, 3 parts of rubber protective wax, 3.5 parts of anti-aging agent, 4 parts of vulcanizing agent, 2 parts of accelerator, 40 parts of carbon black, 2.5 parts of polypropylene fiber, 15 parts of tear-resistant resin and 120 parts of phase change anti-overstretching rod.

[0058] The rest are consistent with Example 1.

Embodiment 3

[0060] A phase change type high tear strength rubber, comprising the following raw materials in parts by weight: 120 parts of natural rubber latex in dry rubber, 60 parts of styrene-butadiene rubber, 60 parts of butadiene rubber, 10 parts of zinc oxide, 8 parts of stearic acid parts, 4 parts of rubber protective wax, 4 parts of anti-aging agent, 6 parts of vulcanizing agent, 3 parts of accelerator, 50 parts of carbon black, 3 parts of polypropylene fiber, 20 parts of tear-resistant resin and 125 parts of phase change anti-overextension rod.

[0061] The rest are consistent with Example 1.

[0062] The present invention can realize the introduction of part of the reinforcing raw material and the phase change anti-overstretching rod 1 in natural rubber, which can significantly improve the tensile strength and tear resistance of rubber products, and the phase change anti-overstretching rod 1 is not damaged under normal conditions. It will not affect the elasticity and other prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com