Standard device for geometric quantity measurement and calibration

A technology of geometric quantities and standard devices, which is applied in the field of standard devices for measurement and calibration of geometric quantities, can solve problems such as lack of unanimous approval, and achieve the effects of wide applicability, improved accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

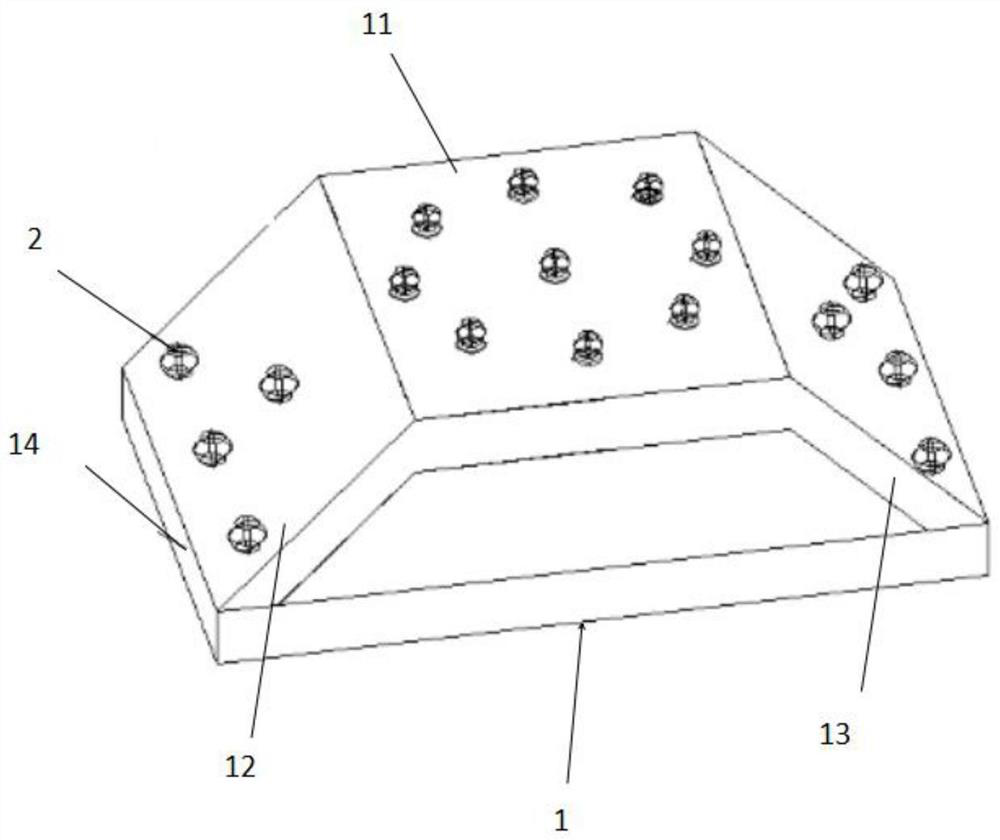

[0030] The first embodiment provides a standard device for measuring and calibrating geometric quantities, such as figure 1 As shown, the device includes: a base 1 and at least one standard ball 2, the base 1 includes a first fixed plate 11, a second fixed plate 12, a third fixed plate 13 and a fourth fixed plate 1, the first fixed plate 1 The fixed plate 11, the second fixed plate 12, the third fixed plate 13 and the fourth fixed plate 14 form a trapezoidal structure, and a hollow space is provided inside the trapezoidal structure, and a hollow structure is adopted to avoid excessive thickness of the base plate As a result, the X-rays of low-power CT cannot penetrate the sample normally, which affects the imaging effect;

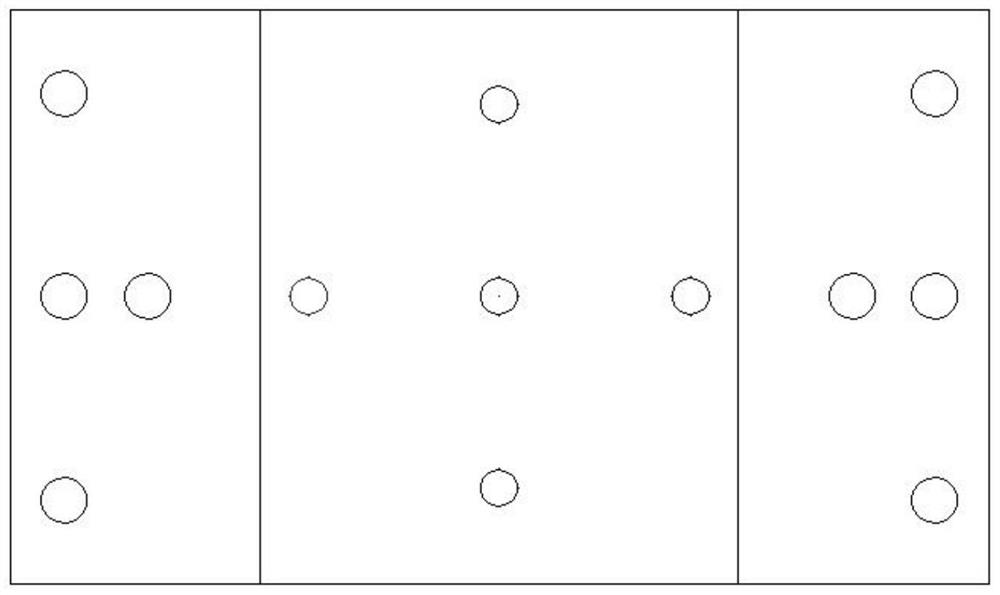

[0031] The first fixing plate 11, the second fixing plate 12 and the third fixing plate 13 are all provided with at least one boss, and the bosses are in one-to-one correspondence with the standard balls 2, and each of the bosses A blind hole is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com