PCB and motor threading, welding and detecting all-in-one machine and operation method thereof

A PCB board, welding detection technology, applied in the field of PCB board and motor threading and welding detection integrated machine, can solve the problems of unoptimistic product qualification rate, difficult manual operation, low product qualification rate, etc., to achieve automatic detection of product fluctuations, saving Welding time, the effect of avoiding manual errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

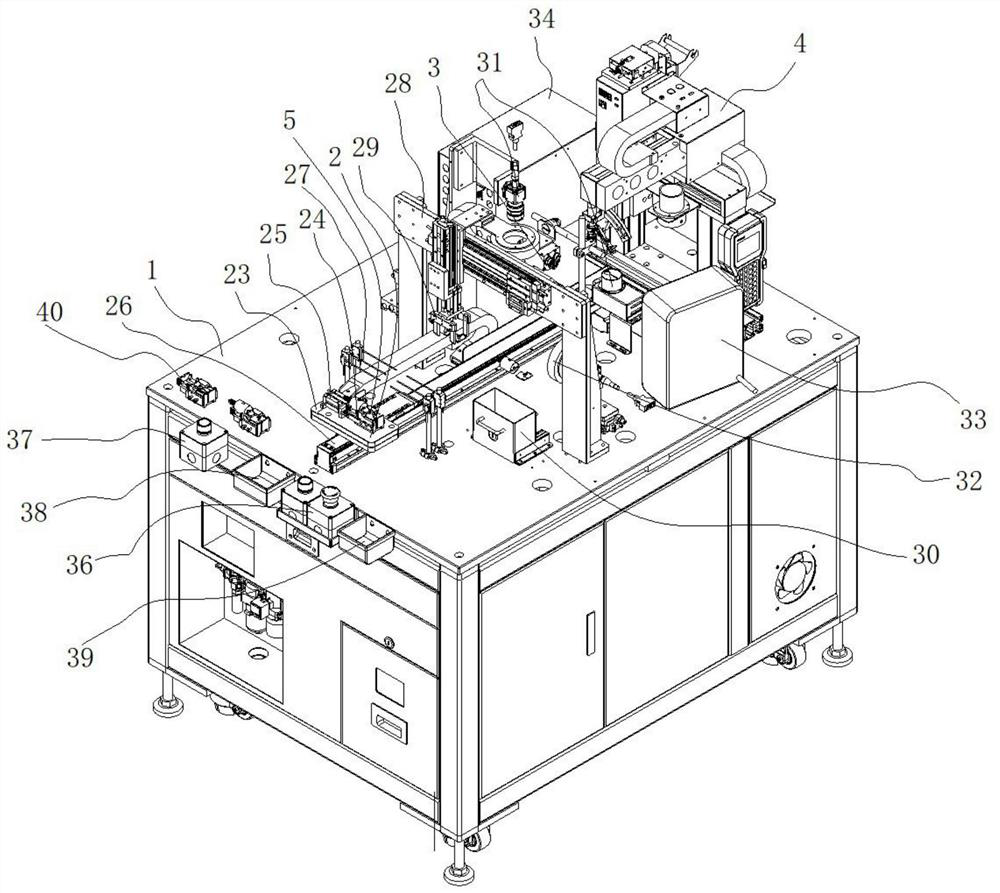

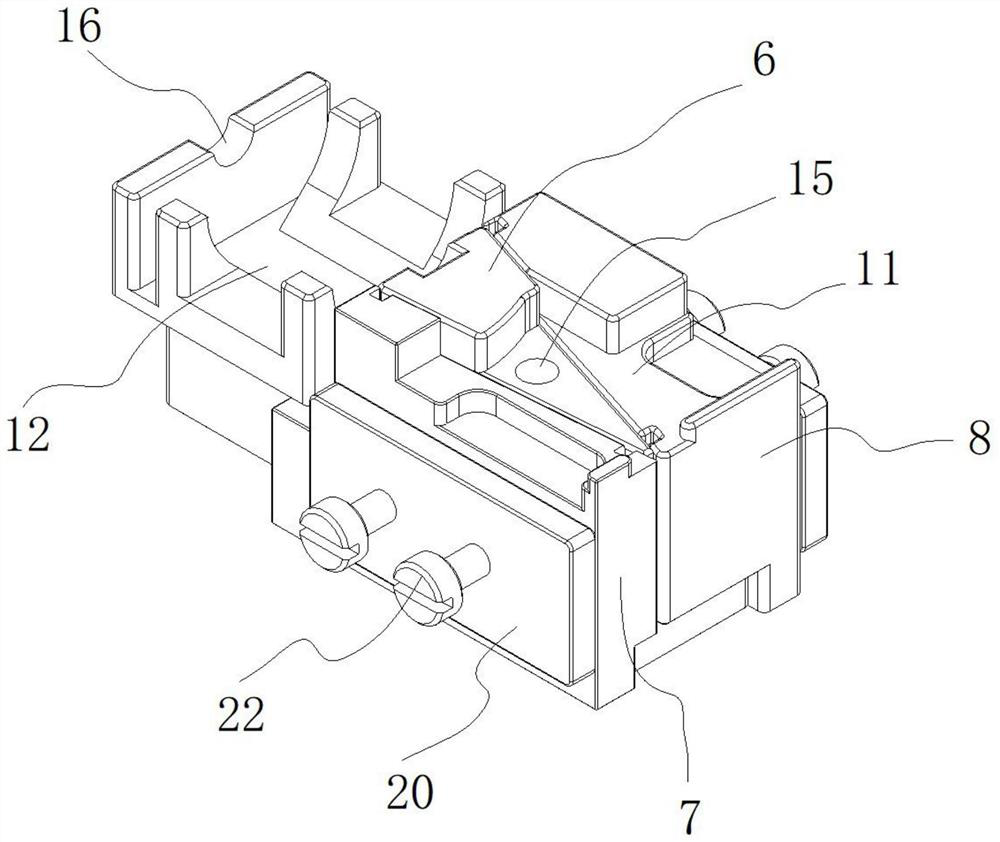

[0059] Embodiment 1: As shown in the figure, a PCB board and motor threading and welding inspection integrated machine, including a frame 1, the upper part of the frame 1 is provided with a displaceable pressing component 2, an image system, a two-dimensional code The barcode scanner 3 and the automatic welding machine 4, the threading fixture 5 is arranged in the pressing assembly 2, and the two-dimensional code scanner 3 scans the two-dimensional code 3 for the workpiece in the threading fixture 5. In contrast, the imaging system performs a photographing and inspection operation on the workpiece in the threading fixture 5 , and the automatic welding machine 4 performs a welding operation on the workpiece in the threading fixture 5 .

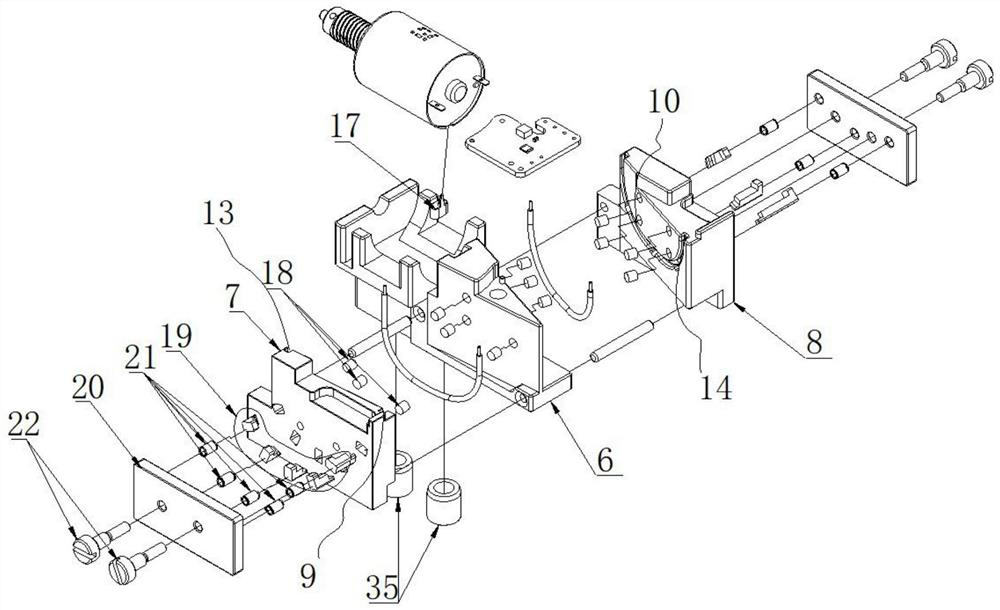

[0060] The threading jig 5 includes a middle jig 6, and the left side wall of the middle jig 6 is provided with a front jig 7 that can be movably separated from the middle jig 6. The side wall is provided with a rear fixture 8 which is movably ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap