Industrial metal ring pressing machine

A ring press, industrial technology, used in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as inconsistent diameters, and achieve good stamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

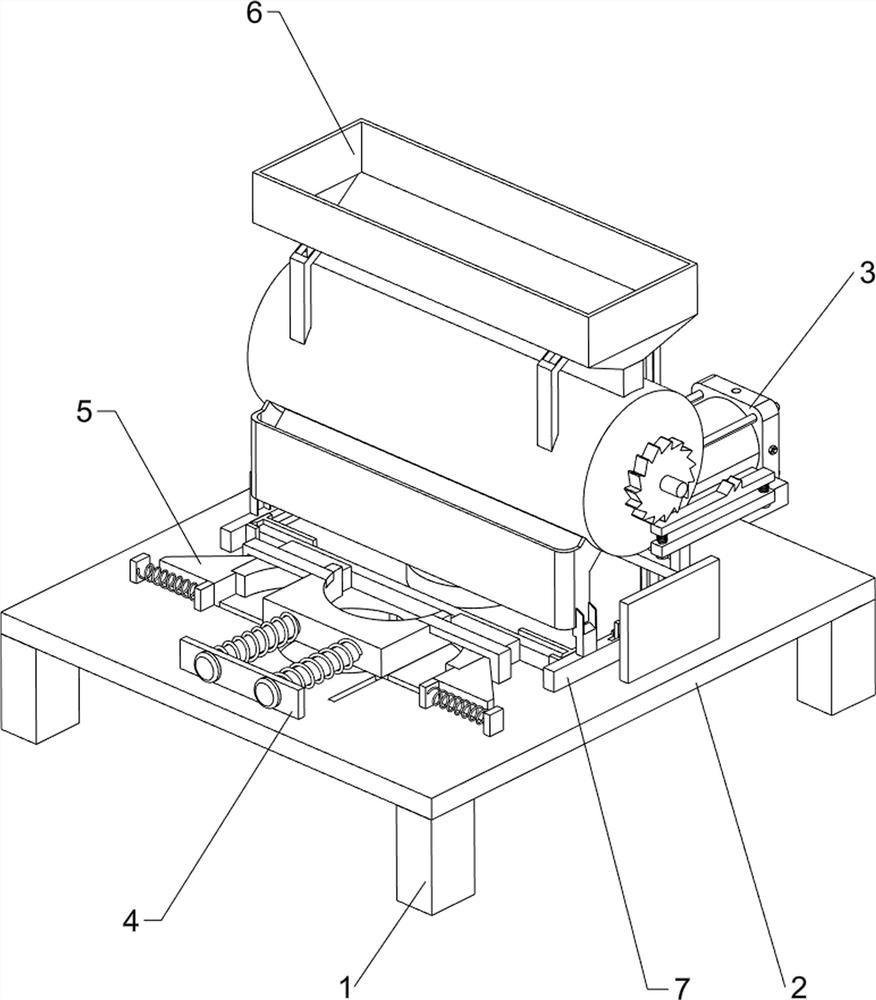

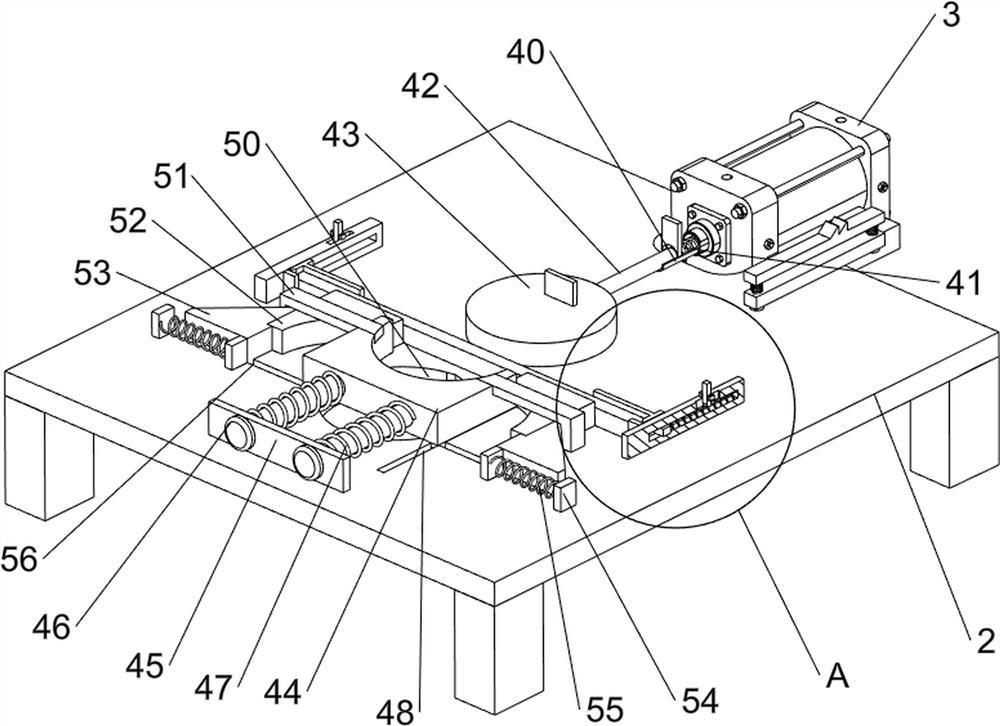

[0023] A metal ring press machine for industrial use, such as Figure 1-2 As shown, it includes support 1, workbench 2, cylinder 3, stamping mechanism 4 and pressure ring mechanism 5, workbench 2 is arranged between the top of support 1, the number of support 1 is 4, and the right side of workbench 2 is provided with The cylinder 3 is provided with a stamping mechanism 4 on the left side of the top of the workbench 2, and a pressing ring mechanism 5 is provided on the left side of the top of the workbench 2.

[0024] When people need to use this machine, first people place the metal bar on the top of the workbench 2 between the stamping mechanism 4, and then start the cylinder 3 to make the telescopic rod of the cylinder 3 move to the left, and the telescopic rod of the cylinder 3 drives the stamping mechanism 4 Move to the left to stamp the metal strip, and then punch the middle part of the metal strip into a semicircle, then the stamping mechanism 4 continues to move to the ...

Embodiment 2

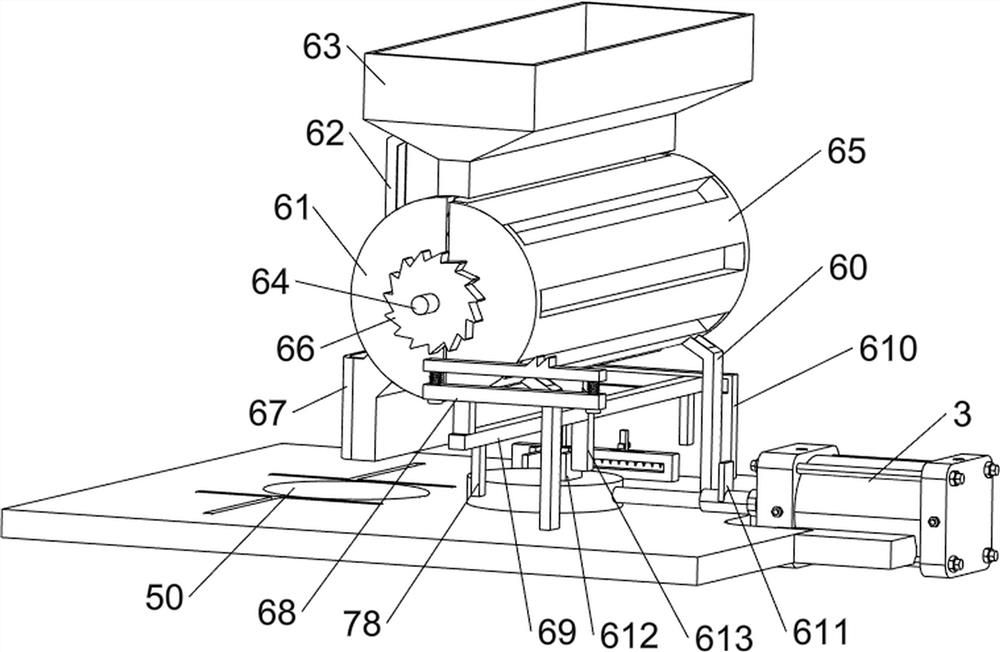

[0030] On the basis of Example 1, such as Figure 3-4As shown, it also includes a blanking mechanism 6. The blanking mechanism 6 includes a first pole 60, a roller 61, a second pole 62, a hopper 63, a first rotating shaft 64, a roller 65, a ratchet gear 66, an unloading Material port 67, ratchet rack 68, moving rod 69, guide block 610, first contact block 611, second contact block 612 and first contact rod 613, the top right side of workbench 2 is symmetrically provided with first support rod 60 A roller 61 is arranged between the first poles 60, a second pole 62 is arranged symmetrically on the left and right sides of the roller 61, a hopper 63 is arranged between the second poles 62, and a second A rotating shaft 64, the first rotating shaft 64 is provided with a roller 65, the roller 65 is located inside the roller 61, the front end of the first rotating shaft 64 is provided with a ratchet gear 66, the left side of the roller 61 is provided with a discharge port 67, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap