Hydraulic assembling device for hydraulic oil cylinder lug ring buffer sleeve

A technology of hydraulic cylinder and assembly device, applied in the field of hydraulic assembly, can solve the problems of inability to monitor assembly parameters at all times, and the assembly process cannot be automated, and achieves the effect of getting rid of high maintenance costs, improving equipment stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

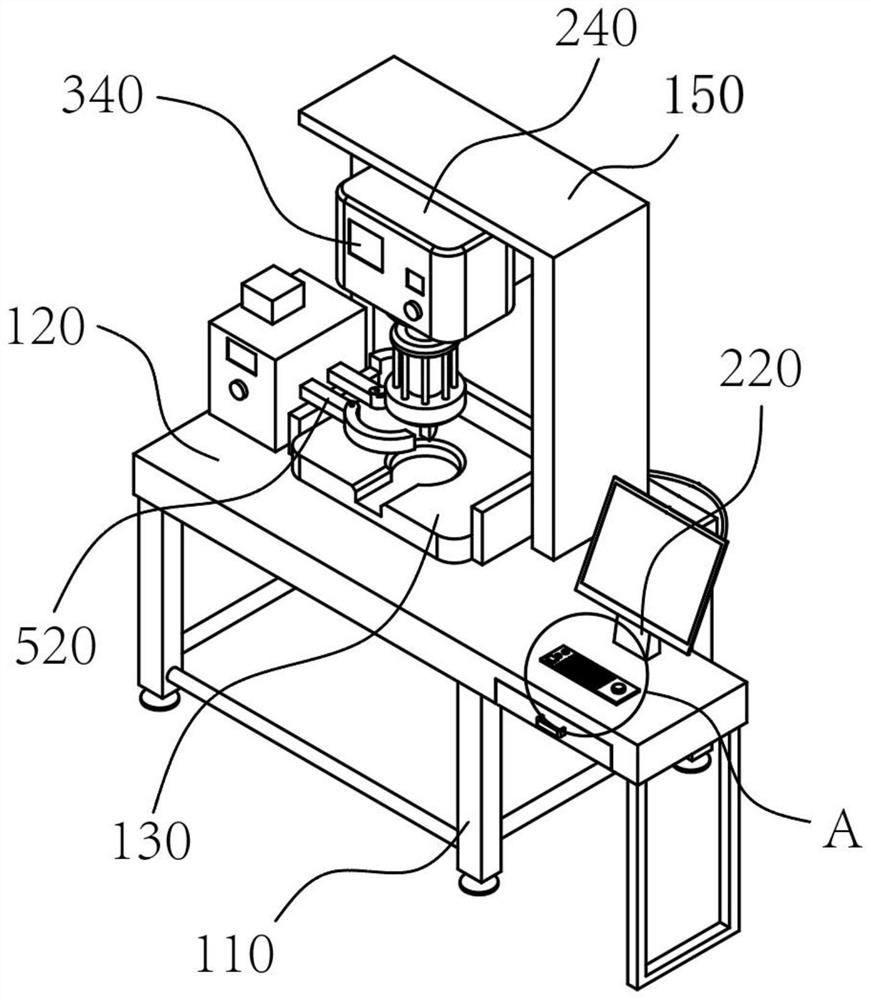

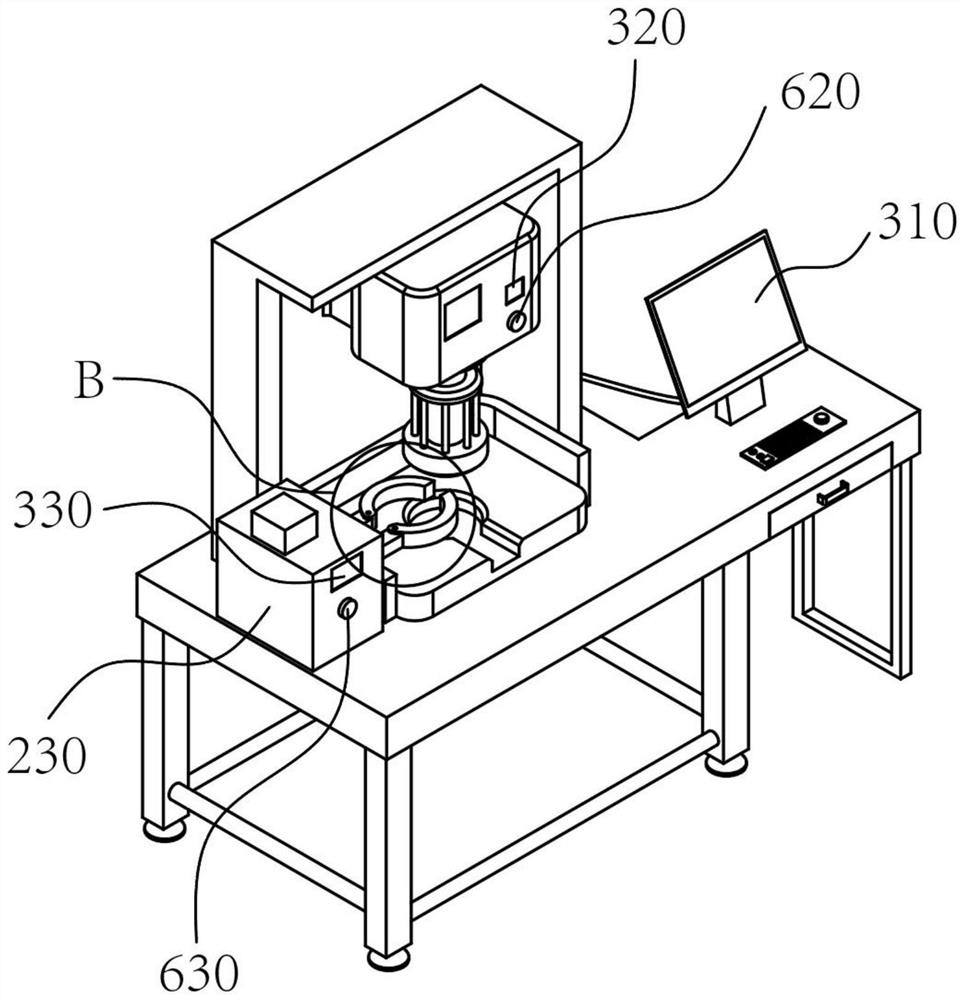

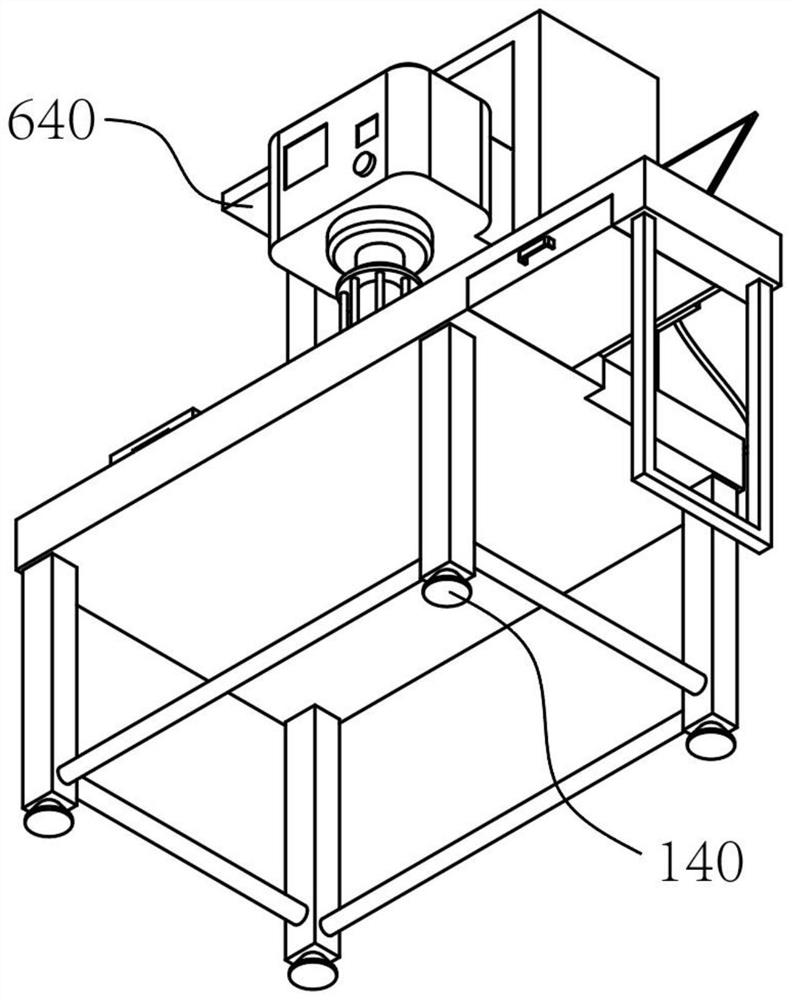

[0032] refer to figure 1—6. The present invention is a hydraulic assembly device for earring buffer sleeves of a hydraulic cylinder, including a support device 100, a control device 200, a monitoring device 300, a stamping device 400, a feeding device 500, and a safety device 600. The support device 100 includes equipment legs 110, working platform 120, workpiece positioning platform 130 and gantry 150, one end of several equipment legs 110 is welded to the surface of working platform 120, wherein, there are four equipment legs 110, which play the role of supporting and fixing, workpiece positioning platform One end of 130 is connected with one surface of working platform 120, one end of gantry frame 150 is connected with one surface of working platform 120, the control device 200 includes microcomputer control center 220, feeding system controller 230 and hydraulic controller 240, one end of microcomputer control center 220 is connected with One surface of the working platfor...

Embodiment 2

[0041] When personnel use it, place the workpiece to be processed firmly on the workpiece positioning platform 130, and execute the predetermined program by operating the main console 210, pushing the hydraulic press 420 to drive the hydraulic stamping shaft 430 to press the high-strength stamping head 410 to move the caliper 510 to the workpiece The tight workpiece is hydraulically assembled to complete one processing. It can cooperate with other equipment and accessories to build a fully automated work assembly line, which greatly improves work efficiency and equipment stability. Braking has the characteristics of simple operation, safety, high efficiency, and intelligence, and it gets rid of the cost of traditional manual processing and high maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com