Ball polishing device

A polishing device and sphere technology, which is applied to grinding drive devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of high energy consumption, uneven polishing, poor stability, etc., to improve stability and safety. performance, polishing uniformity without dead angle, and the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

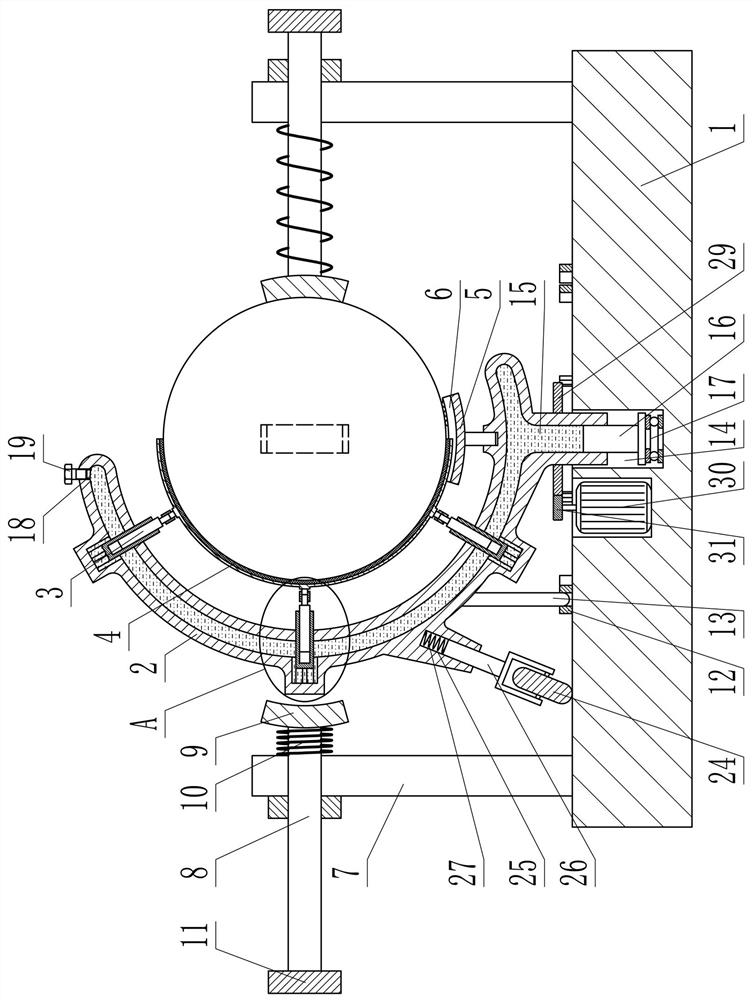

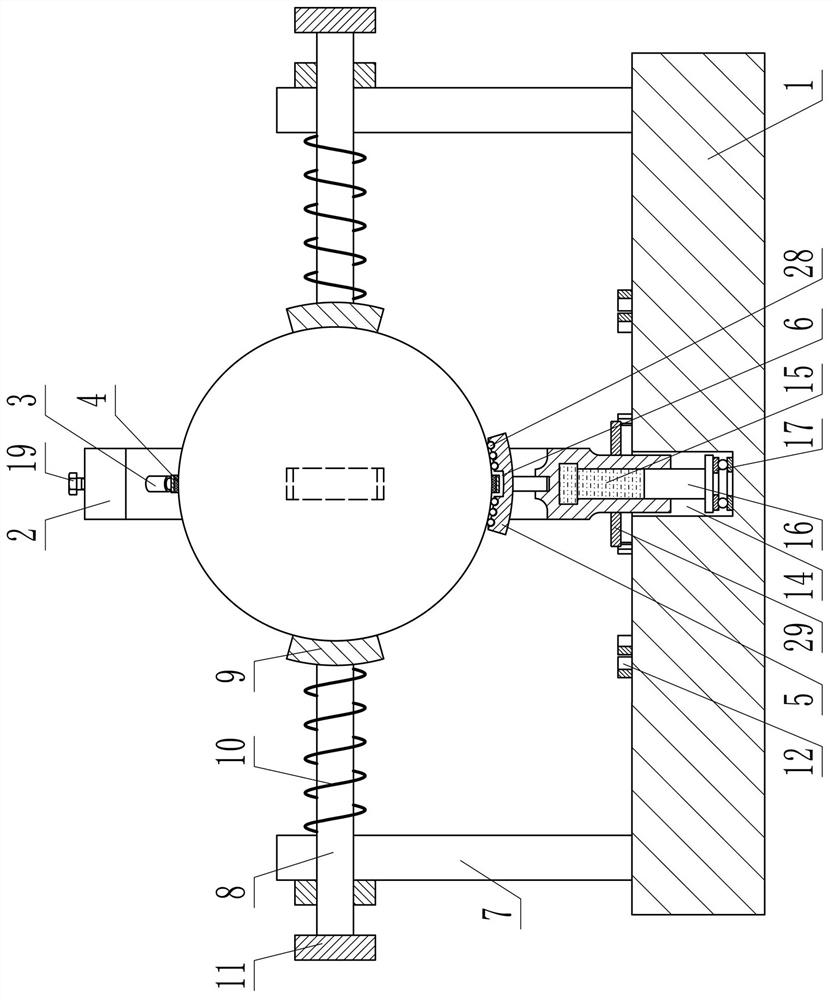

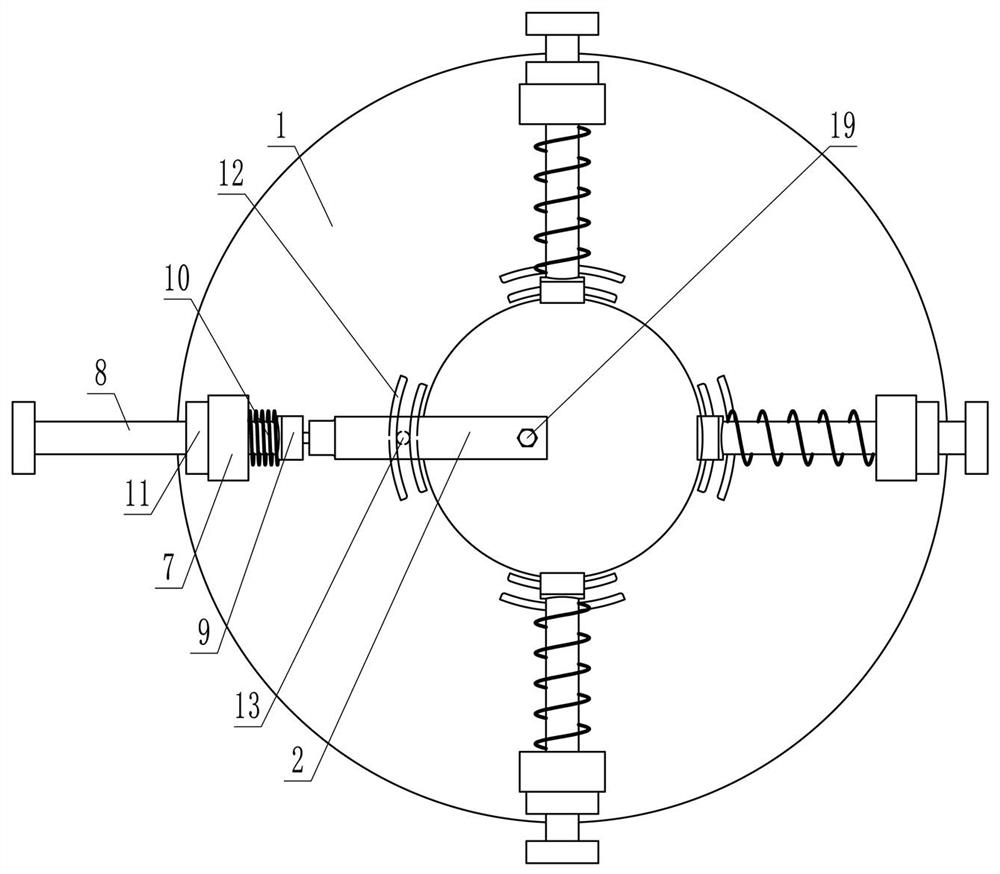

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Depend on Figure 1 to Figure 6 Given, the present invention comprises a base 1, a vertical arc frame 2 is installed on the base 1, the lower end of the arc frame 2 is rotatably installed on the base 1, and a plurality of connecting rods 3 are installed in the arc frame 2 A semicircular polishing sheet 4 concentric with it, a spherical arc-shaped tray 5 is installed at the lower end of the inner side of the arc frame 2, the tray 5 is used to carry the sphere, the upper surface of the tray 5 is provided with an escape groove 6, and the lower end of the polishing sheet 4 It can extend into the avoidance groove 6 so as to reach the lowest point of the sphere; the base 1 is provided with four sets of clamping units that are evenly distributed on the outside of the arc frame 2, and each set of clamping units includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com