A blackboard surface pressing device with auxiliary turning mechanism

A turning mechanism and surface pressing technology, which is applied to home appliances, other home appliances, flat products, etc., can solve the problems of slow speed and inability to turn over automatically, and achieve the effect of convenient pressing and centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

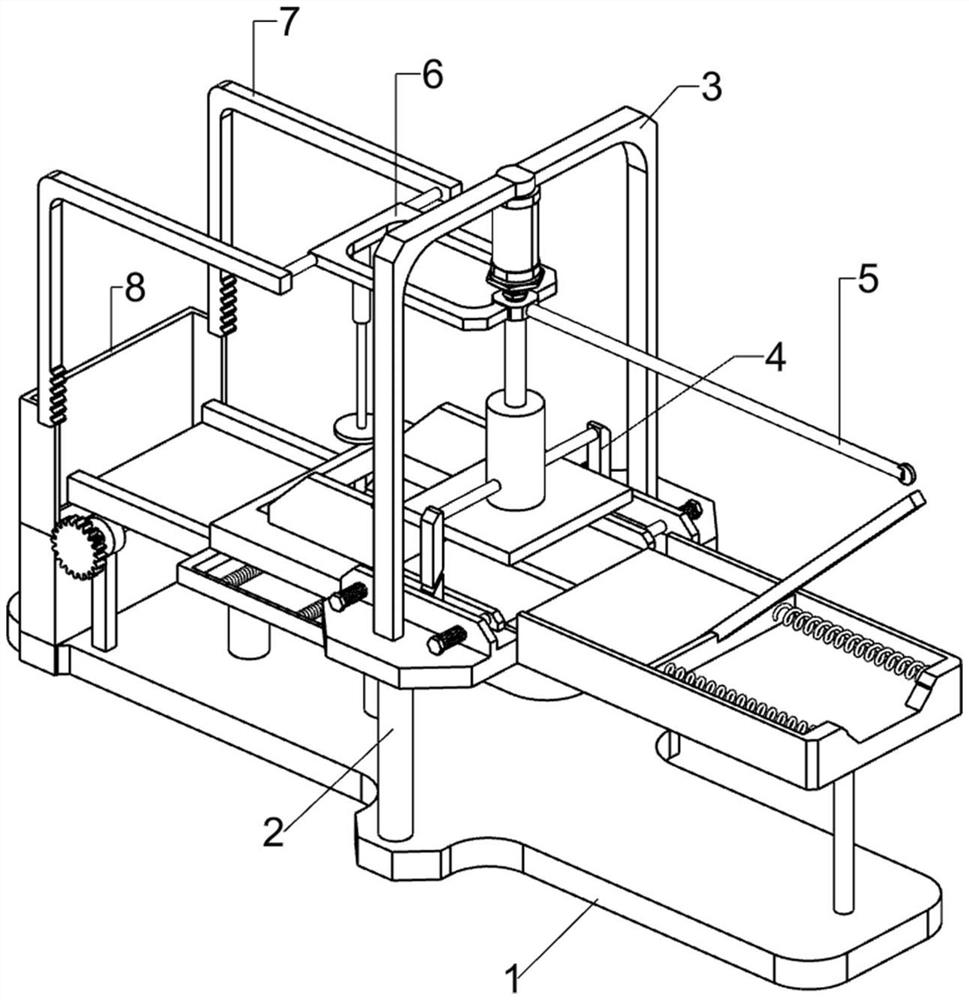

[0069] A blackboard surface pressing device with an auxiliary turning mechanism, such as figure 1 As shown in the figure, it includes a base 1, a support base 2, a pressing mechanism 3 and a limit mechanism 4. A support base 2 is connected to the middle of the upper side of the base 1, a pressing mechanism 3 is connected to the upper side of the support base 2, and the front and rear of the pressing mechanism 3 are connected. Both sides are connected with the limiting mechanism 4 .

[0070]When the equipment needs to be used, the user can place the raw material plate on the support base 2, and then start the pressing mechanism 3, and the pressing mechanism 3 presses the raw material plate on the support base 2, so as to achieve a rapid For the purpose of pressing, the pressing mechanism 3 moves downward to drive the limiting mechanism 4 to move downward. When the interior of the limiting mechanism 4 is in contact, the limiting mechanism 4 moves relatively inwardly. At this tim...

Embodiment 2

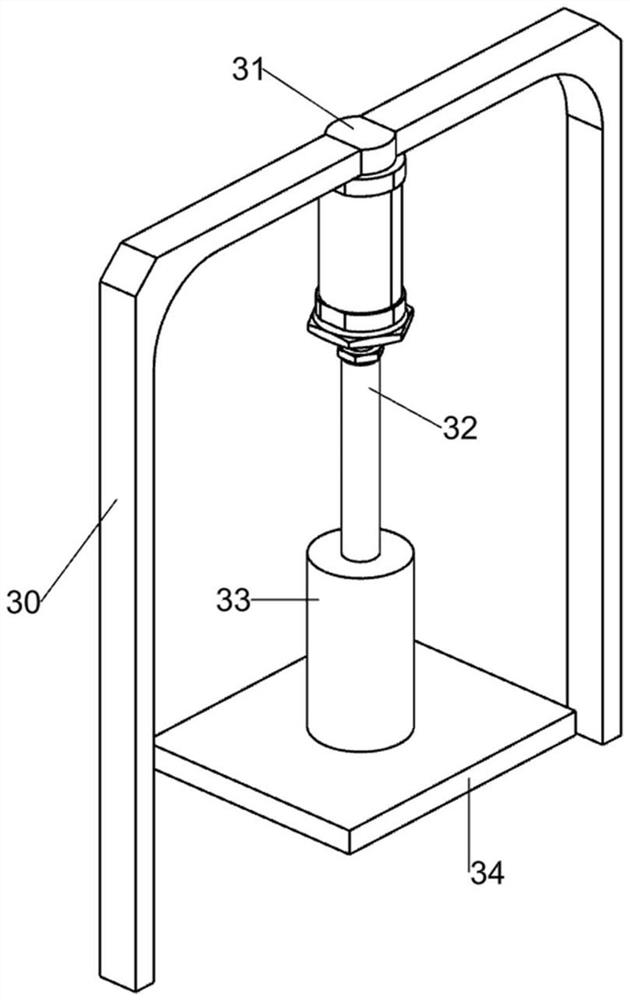

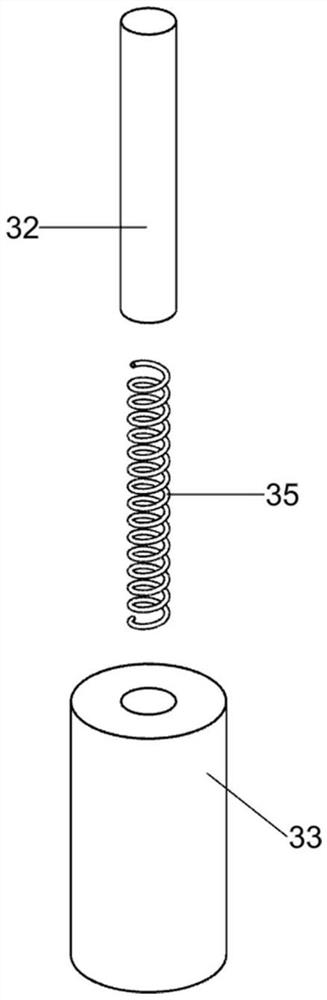

[0072] On the basis of Example 1, as figure 2 and image 3 As shown, the profiling mechanism 3 includes an L-shaped rod 30, a cylinder 31, an air rod 32, a first hollow cylinder 33, a profiling plate 34 and a first spring 35, and the upper part of the support seat 2 is connected with L-shaped rods on both sides at the front and back. 30. A cylinder 31 is connected between the inner sides of the two L-shaped rods 30, a gas rod 32 is connected to the telescopic rod of the cylinder 31, a first hollow cylinder 33 is slidably connected to the gas rod 32, and the bottom of the first hollow cylinder 33 is connected with A first spring 35 is connected between the pressing plate 34 , the bottom end of the gas rod 32 and the upper side of the pressing plate 34 , and the first spring 35 is located in the first hollow cylinder 33 .

[0073] When the user places the raw material plate on the support base 2, the air cylinder 31 is then activated. The extension of the telescopic rod of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com