Embedded accurate balance weight system and method for helicopter

A technology for balancing counterweights and helicopters, applied in the field of helicopter rotors, can solve problems such as the destruction of dynamic balance state, intensified vibration of helicopters, and uncontrollable weight accuracy of counterweights, and achieves the effects of stable quality, avoiding disturbance, and being beneficial to flight quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

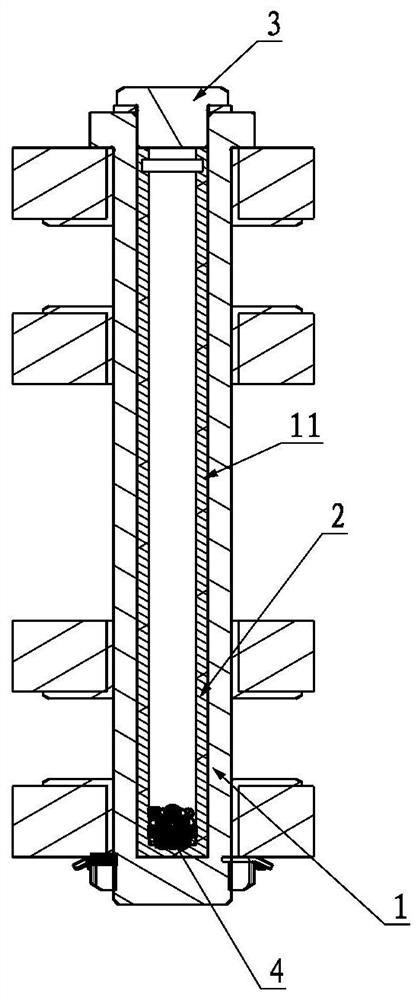

[0037] Such as figure 1 As shown, a helicopter built-in precision balance counterweight system includes blade bolts (1), inner bushing (2), compression screw plug (3), counterweight body (4),

[0038] The blade bolt (1) is installed on the base of the arm of the rotor hub to realize the connection between the hub and the blade; the center of the blade bolt (1) is provided with a cavity (11) communicating with the outside world;

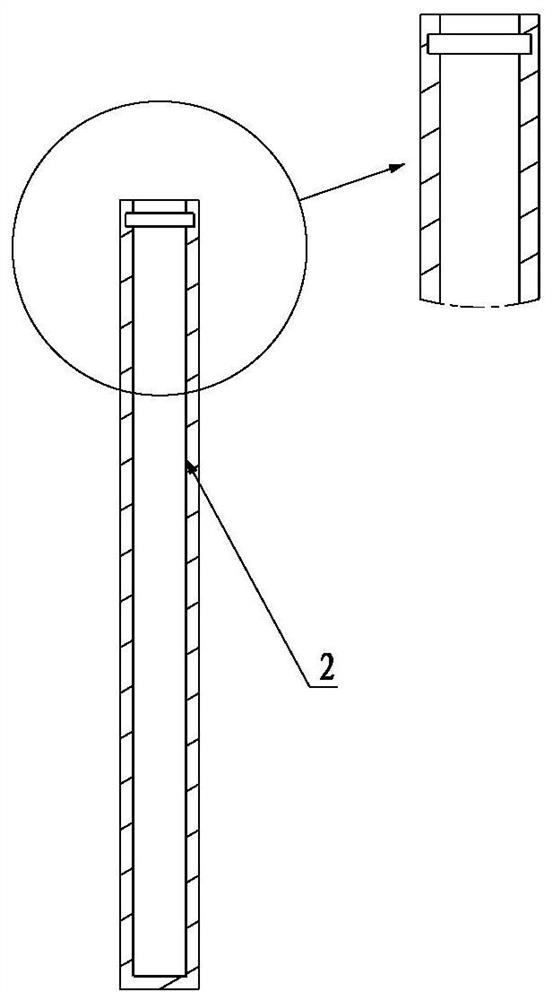

[0039] The shape of the inner bushing (2) is adapted to the cavity (11), installed in the cavity (11), and fits with the cavity (11) in a clearance,

[0040] The counterweight (4) is filled in the inner bush (2);

[0041] The compression screw plug (3) is in sealing cooperation with the upper port of the blade bolt (1);

[0042] The inner wall of the inner bush (2) is provided with a groove near the port of the blade bolt (1) to form a bayonet, so as to facilitate the access of the inner bush (2);

[0043] The weight body (4) is made of tungsten-ba...

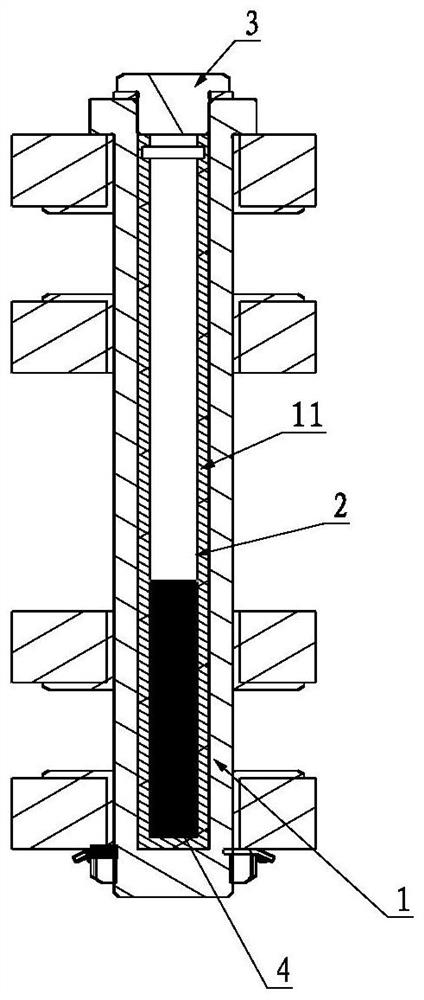

Embodiment 2

[0055]Such as Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that the weight body (4) is made of red liquid, and when filled with liquid, the weight can be accurate to within 0.1g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com