Workpiece transferring device for automatic production line

An automatic production line and transfer device technology, applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of reduced production efficiency, improve processing efficiency, ensure clarity, and avoid long-term no-load running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

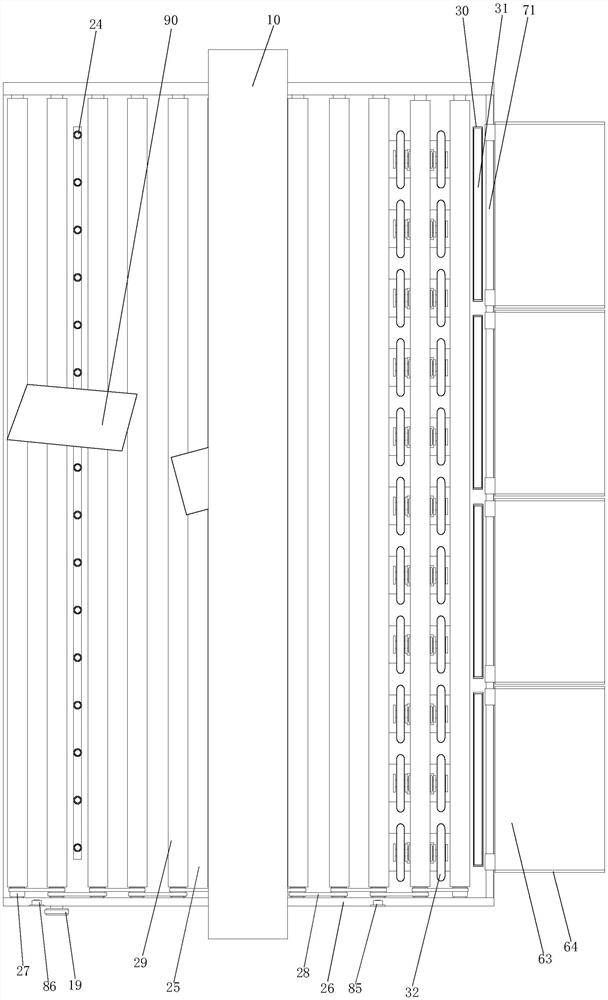

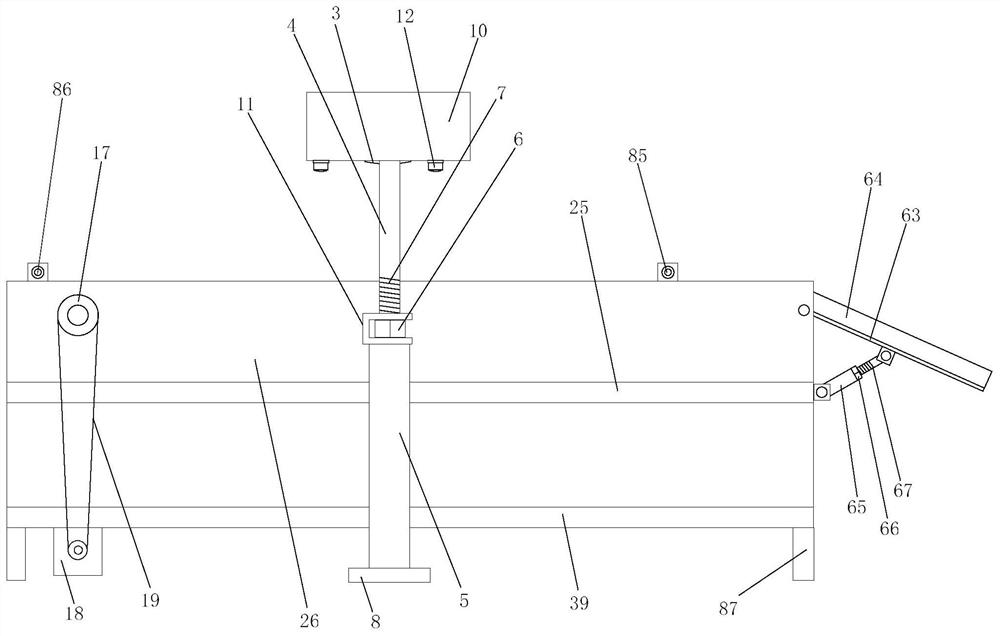

[0024] Such as Figure 1-5 As shown, the workpiece transfer device for an automated production line disclosed by the present invention includes: a transfer transfer roller bed, an image recognition mechanism, a lateral transfer transfer mechanism, a blocking limit mechanism, and various inclined feeding mechanisms;

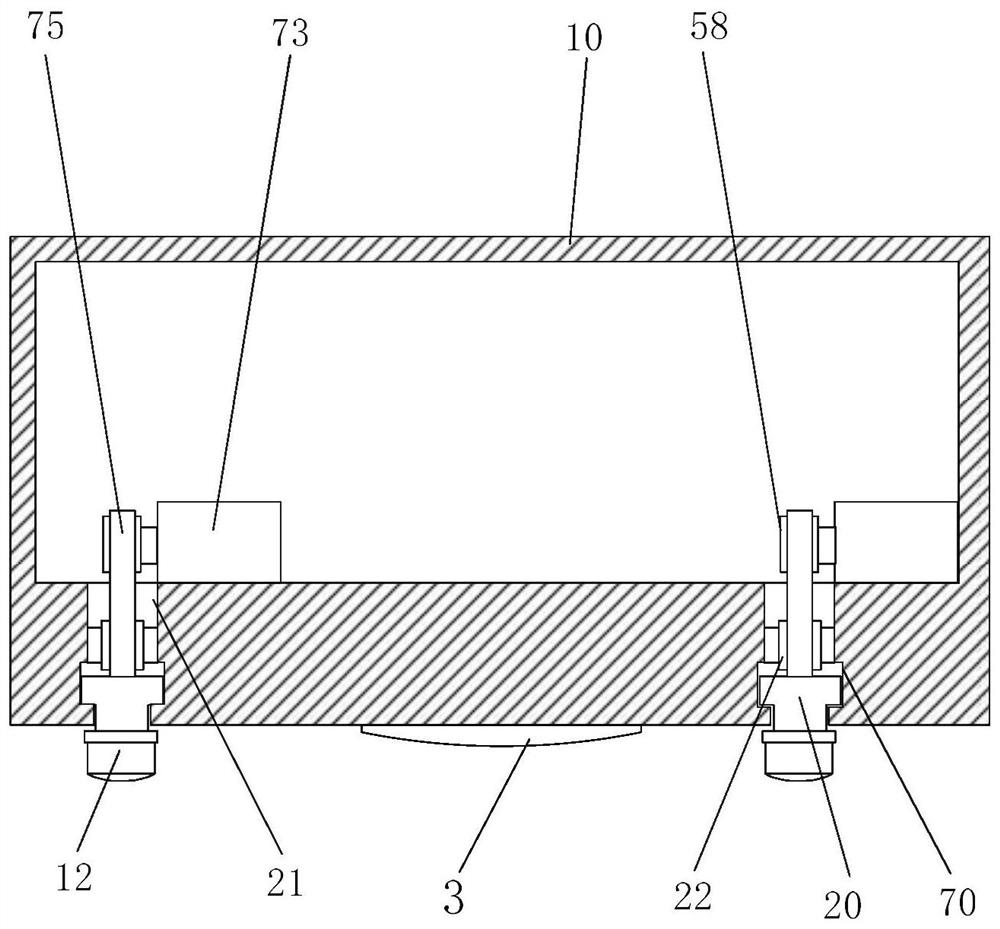

[0025] The image recognition mechanism includes a control box 10, a recognition mounting bracket, a fill light 3 and an image recognition camera 12; the control box 10 is installed above the transfer roller bed through the recognition mounting bracket; a controller is arranged in the control box 10 , a WiFi module and a memory; the fill light 3 and the image recognition camera 12 are installed on the lower side of the control box 10;

[0026] The traversing transfer mechanism is installed on the unloading side of the transfer roller bed, and is used for laterally conveying the workpiece 90 on the unloading side; The rear side is used to block and control the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com