A kind of carboxyl-terminated liquid fluororubber/acrylate rubber blended elastomer and its preparation method

A liquid fluororubber and acrylate technology, applied in the field of rubber materials, can solve problems such as the need to improve mechanical properties, and achieve the effects of avoiding sticking roll phenomenon, good comprehensive performance, and reduced compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

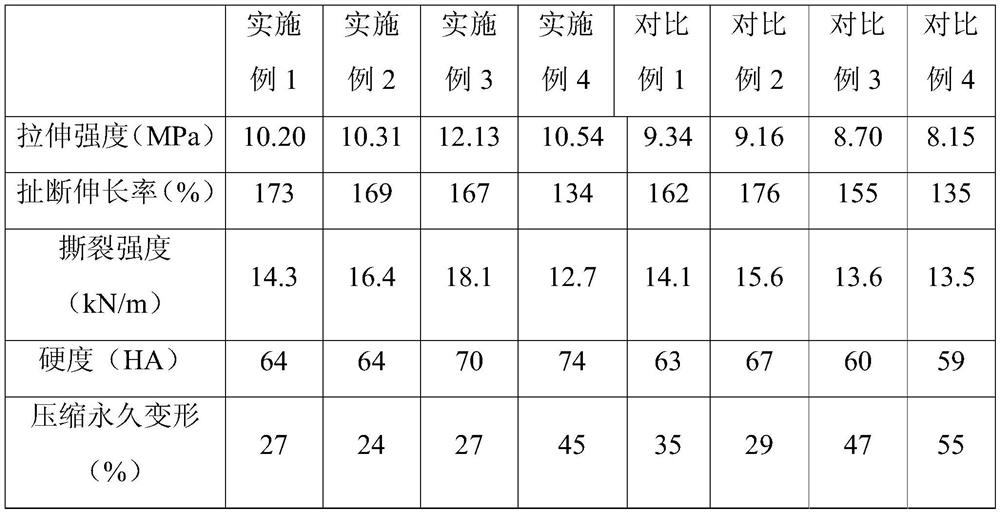

Examples

Embodiment 1

[0085] Prepare the liquid fluororubber / acrylate rubber blended elastomer of the present invention according to the following raw material formula and steps, including the following raw material components by mass:

[0086] Acrylic rubber 95 parts

[0087] Carboxyl-terminated liquid fluororubber 5 parts

[0088] SA 1 copy

[0089] Carbon black N550 30 parts

[0090] Talc powder 10 parts

[0091] TCY 1

[0092] Accelerator BZ 2 parts

[0093] Zirconia 2 parts

[0094] 3 parts calcium carbonate

[0095] Anti-scorch agent CTP 0.5 parts

[0096] The preparation process is as follows:

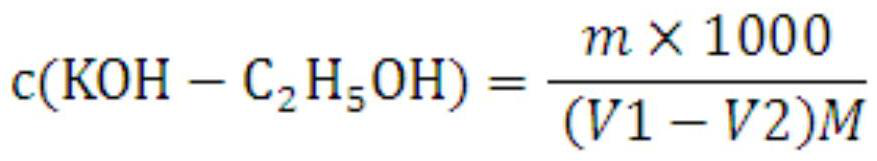

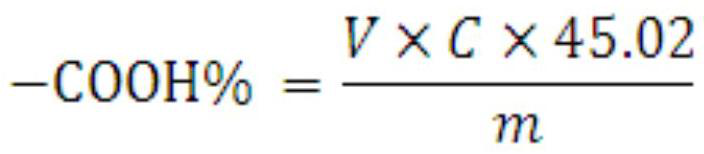

[0097] (1) Preparation of 2.5% liquid fluororubber

[0098] Take 250g of vinylidene fluoride-hexafluoropropylene solid copolymer (number average molecular weight Mn=40w, weight average molecular weight Mw=45w) and dissolve it in 784g of acetone for 12h. Weigh 120g of hydrogen peroxide solution with a mass concentration of 30%, and 60g of potassium hydroxide, and dissolve them in 73mL of wat...

Embodiment 2

[0105] Prepare the liquid fluororubber / acrylate rubber blended elastomer of the present invention according to the following raw material formula and steps, including the following raw material components by mass:

[0106] Acrylic rubber 90 parts

[0107] Carboxyl-terminated liquid fluororubber 10 parts

[0108] Fumed white carbon black 40 parts

[0109] clay 10 parts

[0110] SA 1 copy

[0111] TCY 1

[0112] Accelerator BZ 2 parts

[0113] Titanium oxide 4 parts

[0114] 1 part magnesium carbonate

[0115] Anti-scorch agent CTP 0.5 parts

[0116] The preparation process is as follows:

[0117] (1) Preparation of 3% liquid fluororubber

[0118] Take 250g of vinylidene fluoride-hexafluoropropylene solid copolymer (number average molecular weight Mn=40w, weight average molecular weight Mw=45w) and dissolve it in 784g of acetone for 12h. Weigh 150g of hydrogen peroxide solution with a mass concentration of 30%, and 80g of potassium hydroxide, and dissolve them in 98mL ...

Embodiment 3

[0124] Prepare the liquid fluororubber / acrylate rubber blended elastomer of the present invention according to the following raw material formula and steps, including the following raw material components by mass:

[0125] Acrylic rubber 85 parts

[0126] Carboxyl-terminated liquid fluororubber 15 parts

[0127] Carbon black N330 50 parts

[0128] SA 1 copy

[0129] TCY 1

[0130] Accelerator BZ 2 parts

[0131] Zinc oxide 2 parts

[0132] 3 parts sodium carbonate

[0133] Anti-scorch agent CTP 0.5 parts

[0134] The preparation process is as follows:

[0135] (1) Preparation of 3.5% liquid fluororubber

[0136] Take 250g of vinylidene fluoride-hexafluoropropylene solid copolymer (number average molecular weight Mn=40w, weight average molecular weight Mw=45w,) and dissolve it in 784g of acetone for 12h. Weigh 170g of hydrogen peroxide solution with a mass concentration of 30%, and 100g of potassium hydroxide, and dissolve them in 122mL of water. Add hydrogen peroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com