Anti-sulfuration plate-type thick film fixed resistor and production method thereof

A technology of fixed resistance and anti-vulcanization sheet, which is applied in the manufacture of thick film resistors, resistors, resistors, etc., can solve the problems of easy vulcanization of electrodes, achieve the effects of not easy vulcanization, low manufacturing cost, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

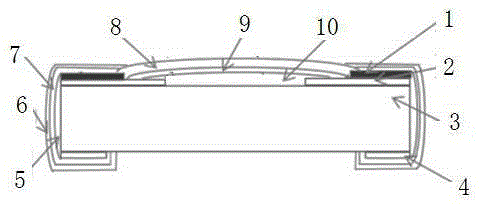

[0025] figure 1 A schematic diagram of the basic structure of the present invention is given, an anti-sulfurization chip thick film fixed resistor, including a ceramic substrate 3, a surface electrode 2, a back electrode 4, a terminal electrode 5, a resistor body 10, and a tin-plated layer 6 , nickel plating layer 7, primary glass 9, secondary glass 8, nickel-chromium isolation layer 1 on the surface electrode. The primary glass is located on the resistor body, and the secondary glass is located on the primary glass. The surface electrode, back electrode, terminal electrode, and resistor body are all located on the ceramic substrate, and the nickel-plated layer is located on the outer surface of the surface electrode, back electrode, and terminal electrode. , the tin layer is located on the outer surface of the nickel layer,

[0026] The present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com