Enzymolysis apparatus and method for embryonic egg white

An embryonic egg, enzymatic hydrolysis technology, applied in the field of enzymatic hydrolysis, can solve the problems of high local temperature, unfavorable egg white enzymatic hydrolysis, low enzymatic hydrolysis rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

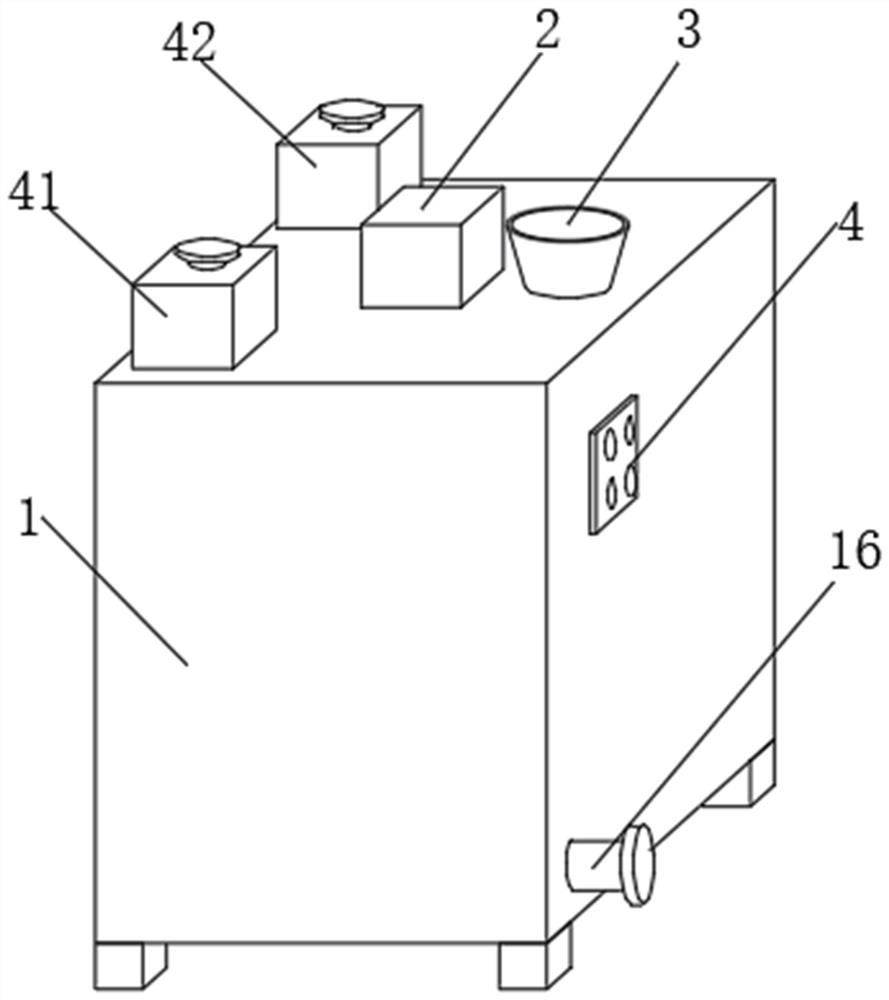

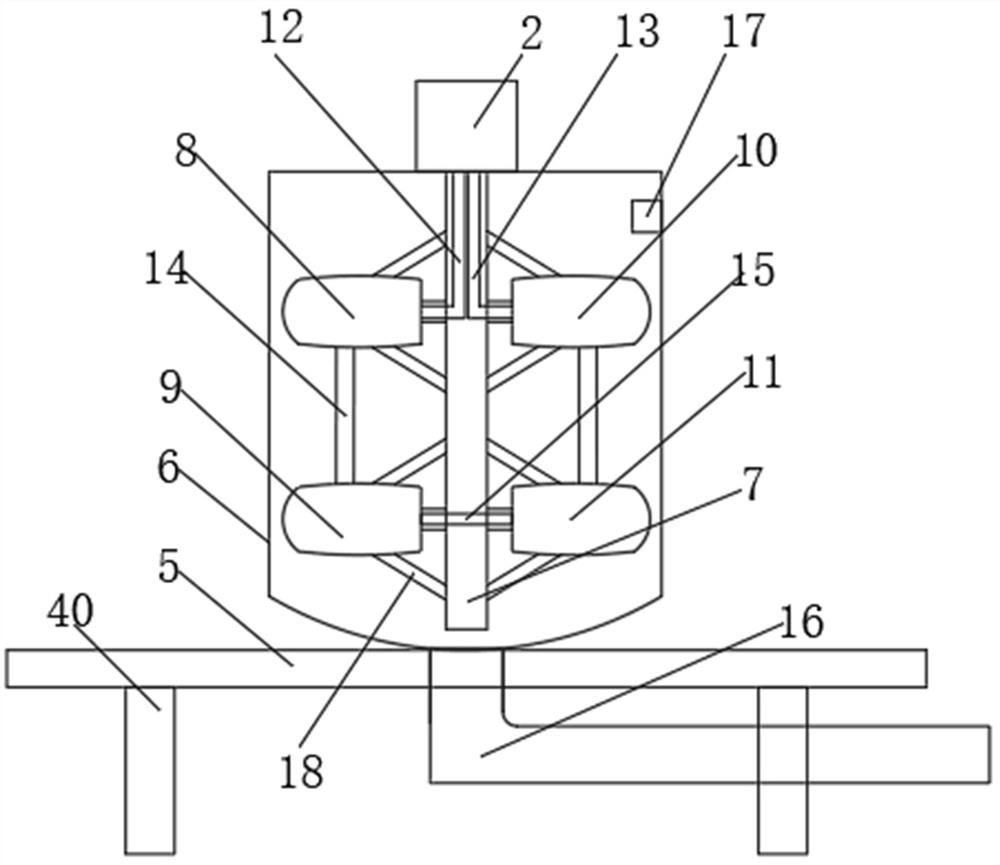

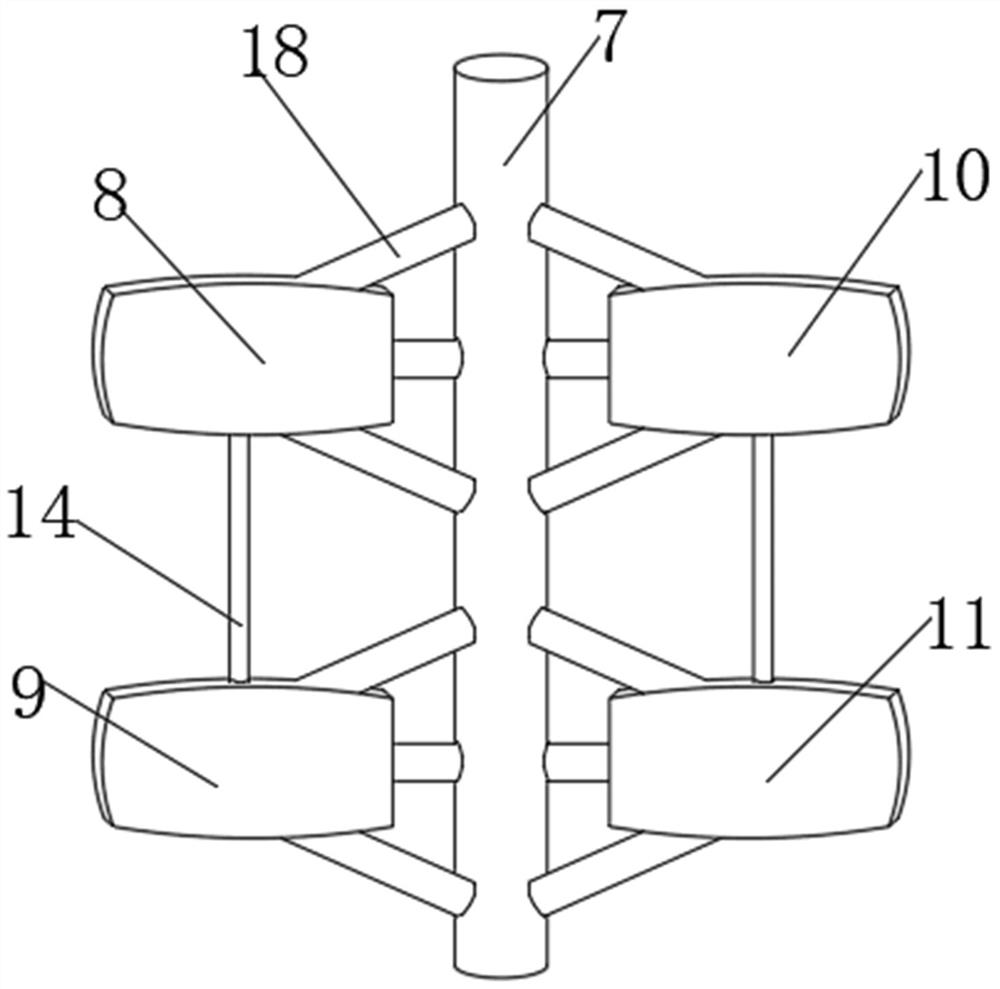

[0030] Such as Figure 1-7 As shown, an enzymolysis device for egg whites of embryonated eggs includes a main box (1), a driving motor (2) is installed on the upper end of the main box (1), and a first The water tank (41) and the second water tank (42), the inner bottom of the main box (1) is equipped with a support frame (40), the upper end of the support frame (40) is connected with the installation base plate (5), and the installation base plate (5) An enzymolysis tank (6) is arranged on the upper end surface of the middle part of the enzymolysis tank (6), and two sets of sliding grooves (19) are provided on the upper end surface of the installation bottom plate (5) on both sides of the enzymolysis tank (6). Sliding blocks (20) are installed, the upper ends of one set of sliding blocks (20) are fixedly connected with the left temperature control splint (21), and the upper ends of the other set of sliding blocks (20) are fixedly connected with the right temperature control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com