An electromagnetic heating temperature control device for the following wheel pairs in a low temperature environment

A low-temperature environment and temperature control device technology, applied in the direction of induction heating device, induction heating control, induction heating, etc., can solve the problems of rising temperature of surrounding components or environment, difficulty in achieving contact heating, heat conduction loss, etc., and achieve long service life, Reduce heating time and reduce the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

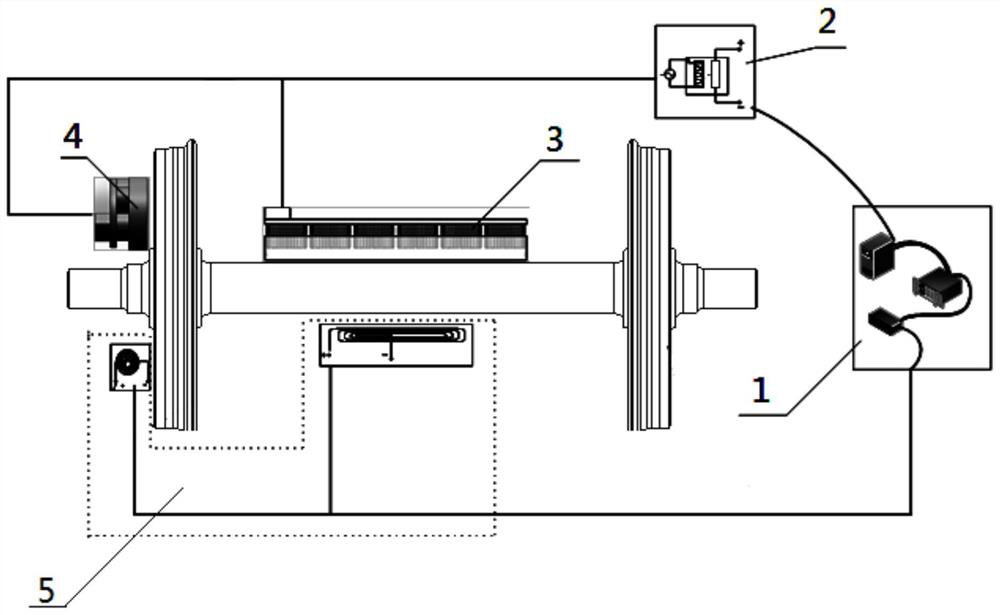

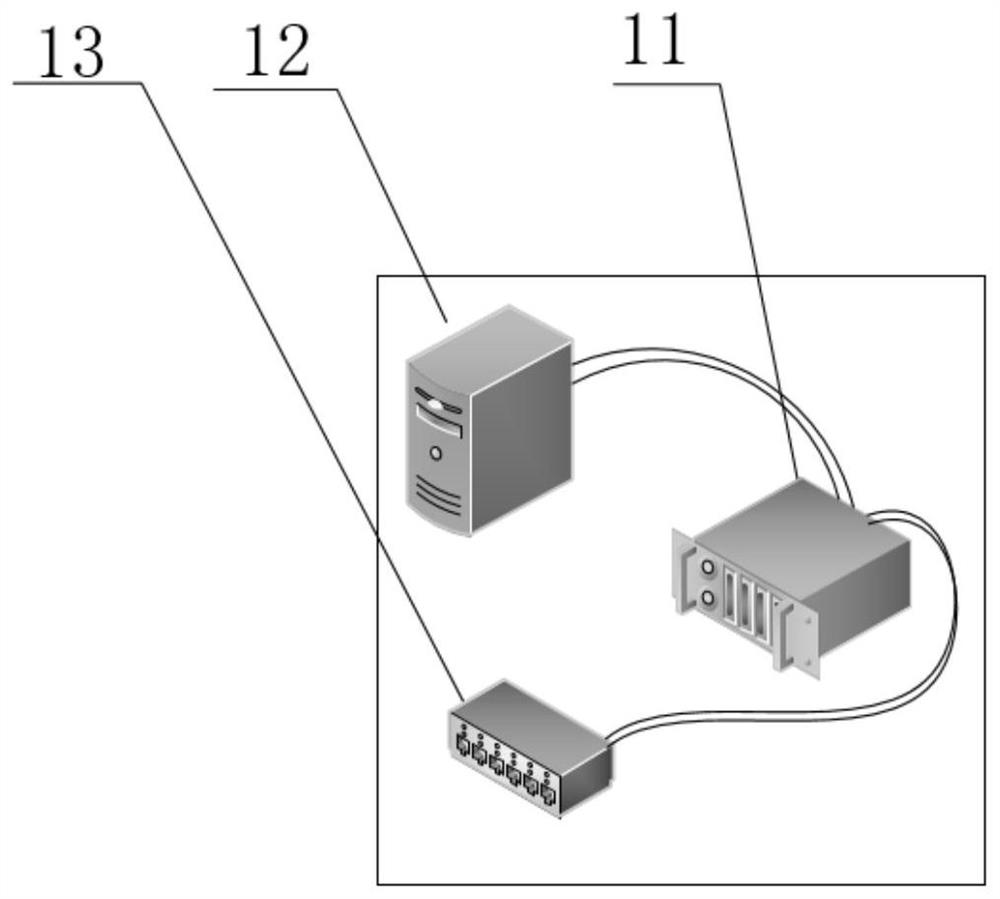

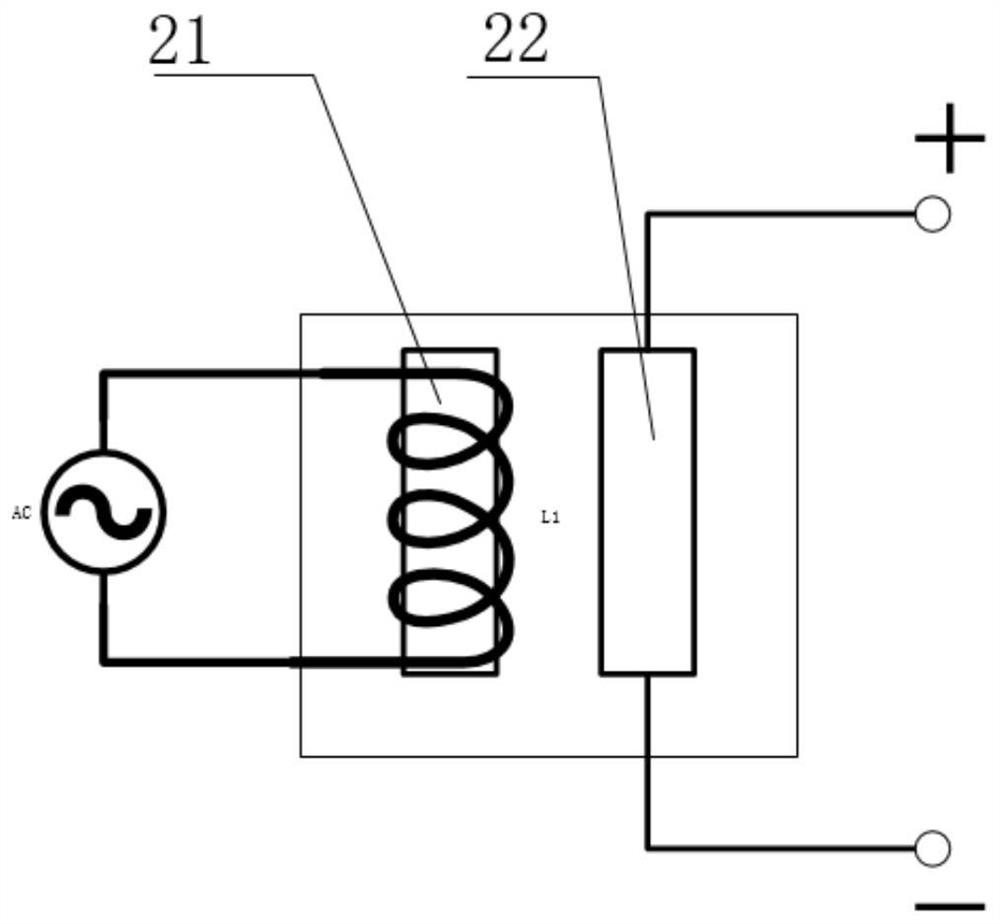

[0043] The following wheel pair electromagnetic heating temperature control devices in low temperature environment include eddy current induction detector 5, electromagnetic heating temperature control actuator 1, excitation power supply 2 and electromagnetic heater, which are connected in sequence through lines, see figure 1 , the electromagnetic heater includes a shaft type electromagnetic heater 3 and a disc type electromagnetic heater 4, the shaft type electromagnetic heater 3 is non-contact arranged above the wheel axle, and the disc type electromagnetic heater 4 is non-contact The contact is located on one side of the wheel tread. Disk support 42, shaft support 32, disk eddy current induction detector 52 and shaft type eddy current induction detector 51 are all fixed on the wheel tread side by the mode of installing support below the train, and disk support 42 and disk eddy current The distance between the induction detector 52 and the wheel surface of the wheel is 15-60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com