Organic material fertilizer making machine and fertilizer making method

A technology of organic matter and organic waste, applied in the field of organic fertilizer making machine and fertilizer making, can solve the problems of long time to decompose organic matter, high maintenance cost, easy to kill microorganisms, etc., to avoid sour and peculiar smell overflow, assembly and maintenance Convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

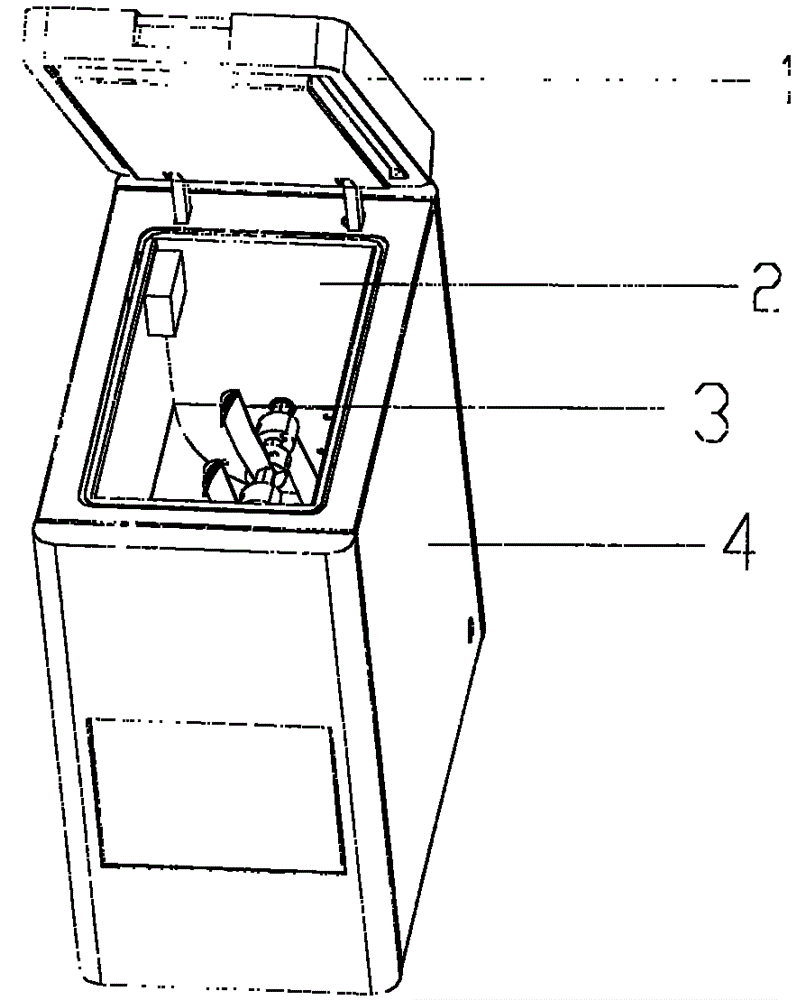

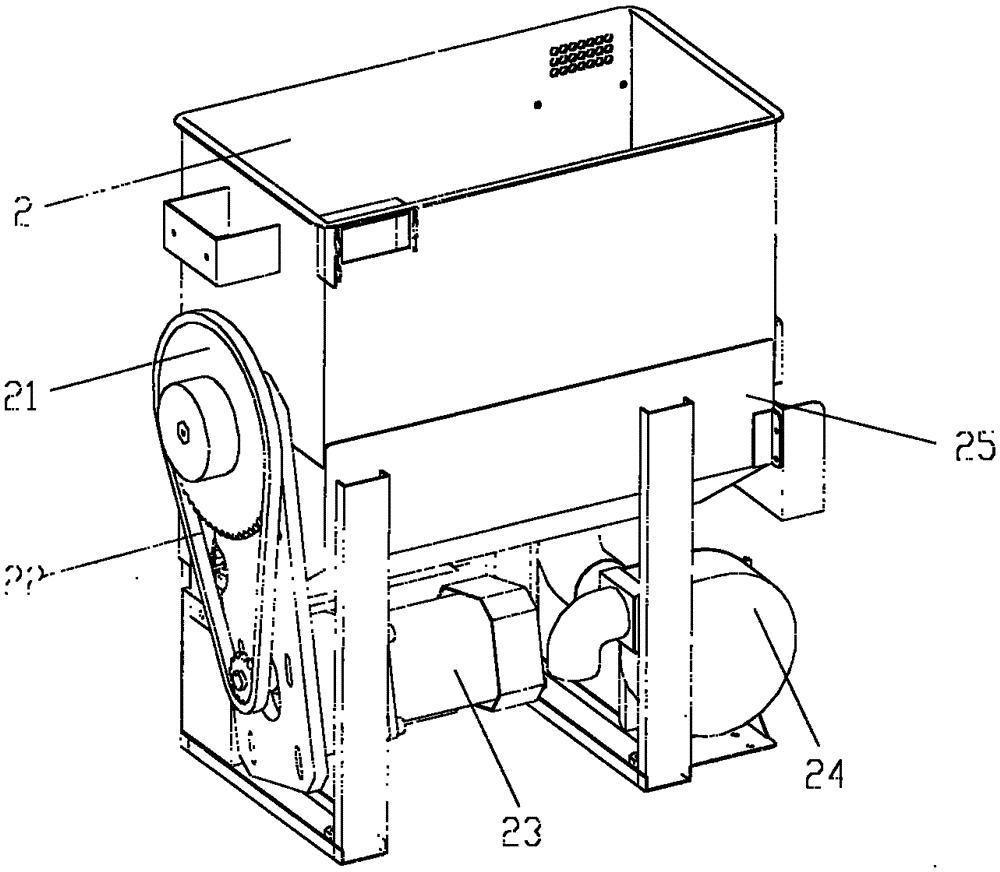

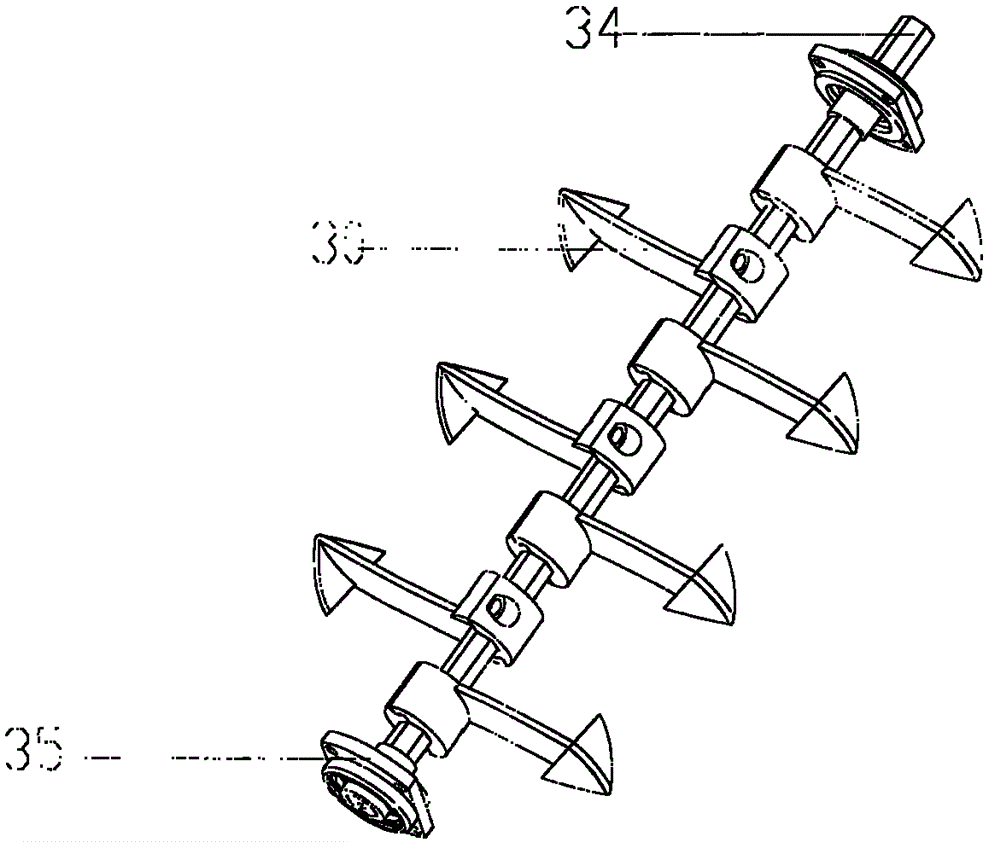

[0023] like figure 1 and figure 2 As shown, one of the objects of the present invention is to provide a kind of organic fertilizer making machine, comprising heat preservation barrel cover 1, stainless steel inner barrel 2 and heat preservation shell 4, the bottom of described stainless steel inner barrel 2 is provided with water bath type constant temperature water tank 25, and described constant temperature water tank The lower part of 25 is provided with ventilation fan 24 and reduction motor 23, and the side part of the stainless steel inner barrel 2 is provided with stirring sprocket 21, and the stirring sprocket 21 is connected to the driving sprocket of reduction motor 23 through belt 22 as a driven sprocket superior. A stirring structure 3 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com