Washing machine

A washing machine and inner drum technology, applied in the field of washing machines, can solve the problems of wasting washing water, reducing user experience, and affecting washing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

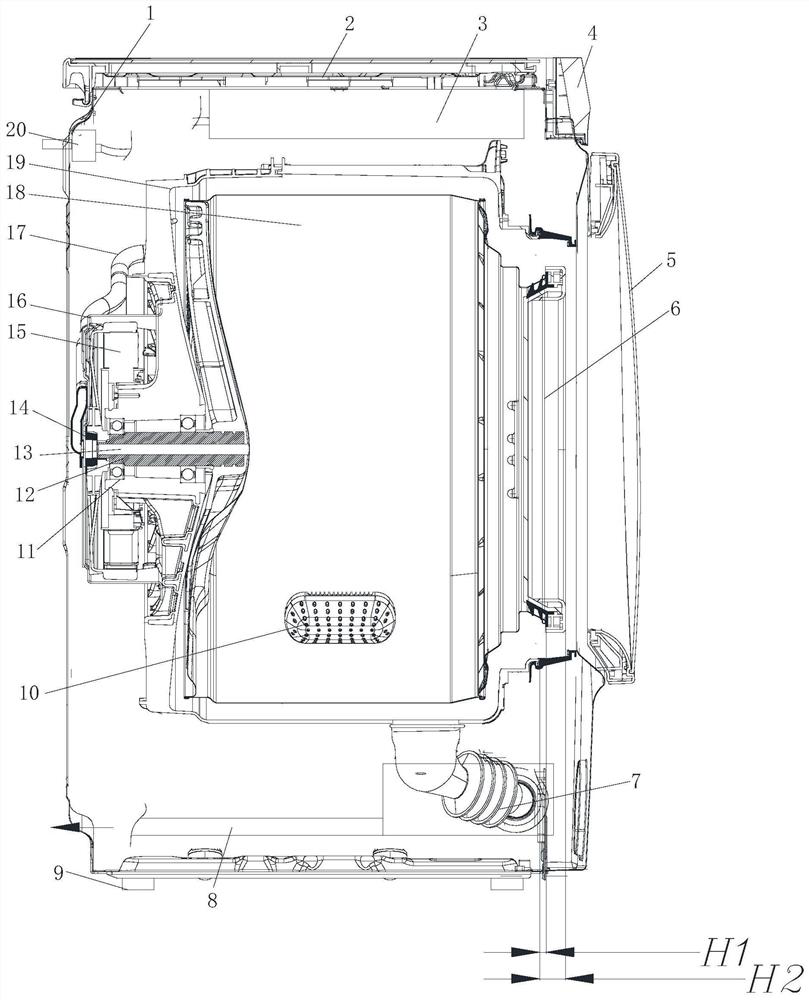

[0062] Such as Figure 1-Figure 8 Shown, a kind of washing machine of the present embodiment comprises:

[0063] The inner cylinder 18 has a washing chamber for independently holding washing water;

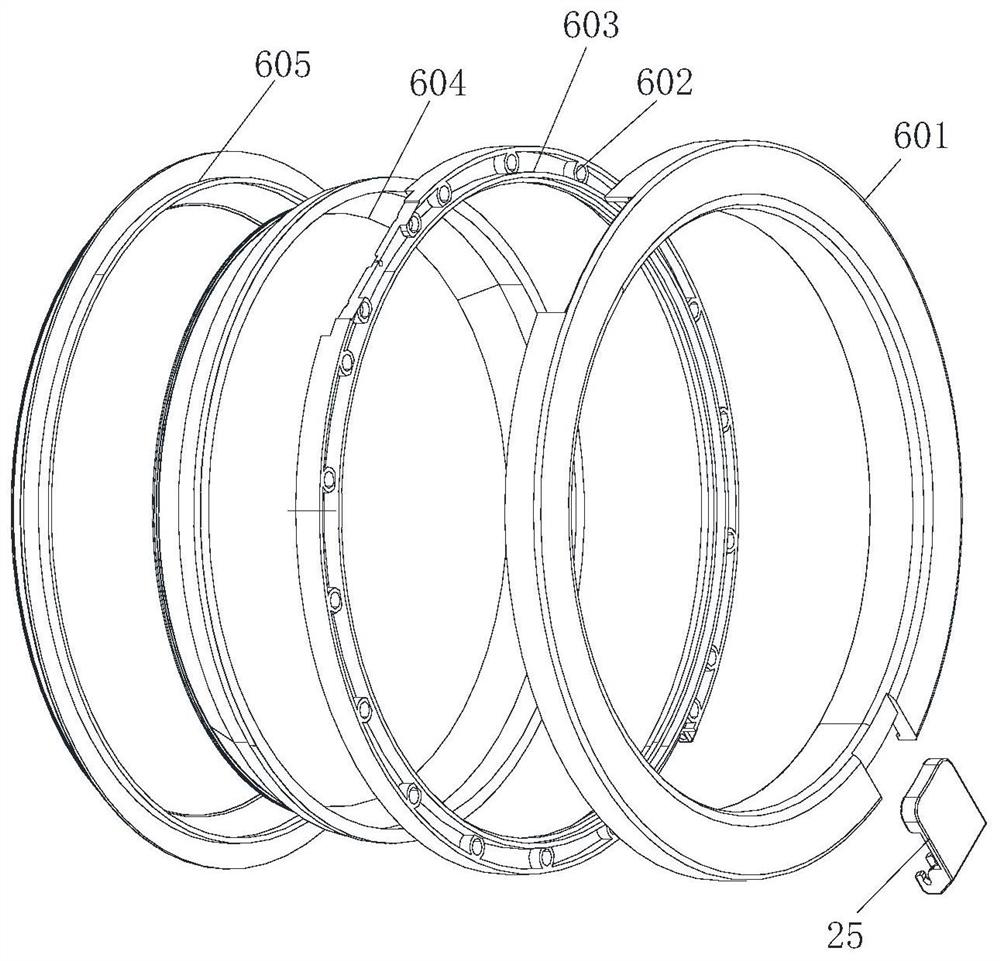

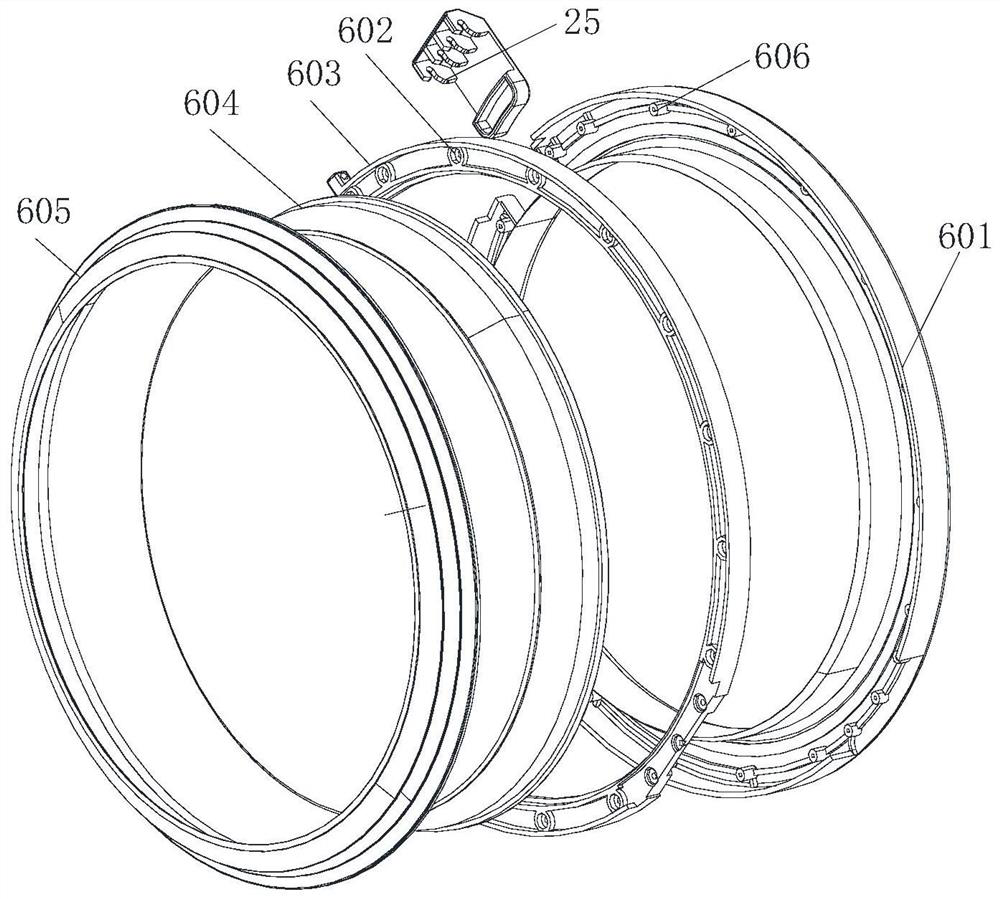

[0064] The inner cylinder door 6 is installed on the mouth of the inner cylinder 18 which can be opened and closed;

[0065] The inner cylinder door 6 includes a door inner shell 603, a door body shell 601 and a door inner lining 604,

[0066] The door inner lining 604 is clamped and fixed between the door inner shell 603 and the door outer shell 601 .

[0067] In this embodiment, the inner cylinder 18 is sealed by installing an openable and closable inner cylinder door 6 on the mouth of the inner cylinder 18 to form a washing chamber containing washing water.

[0068] As an implementation of this embodiment, the door lining 604 described in this embodiment includes a plugging portion that matches the shape of the mouth of the inner cylinder 18 and a connecting portion 615 loca...

Embodiment 2

[0083] Such as Figure 9-Figure 15 Shown, a kind of washing machine of the present embodiment comprises:

[0084] The inner cylinder 18 has a washing chamber for independently holding washing water;

[0085] The inner cylinder door 6 is installed on the mouth of the inner cylinder 18 which can be opened and closed;

[0086] And the rotating shaft structure, the inner cylinder door 6 is rotatably installed on the mouth of the inner cylinder 18 by the rotating shaft structure.

[0087] The inner cylinder door 6 of this embodiment is rotatably installed on the mouth of the inner cylinder 18 through a rotating shaft structure to realize the closing and opening of the inner cylinder.

[0088] Specifically, the rotating shaft structure described in this embodiment includes a rotating shaft seat 24, a rotating shaft 23 and a connecting arm 49. The rotating shaft seat 24 is fixedly installed on the wall of the inner barrel 18, and the rotating shaft 23 is installed on the rotating s...

Embodiment 3

[0108] Such as Figure 16-Figure 18 Shown, a kind of washing machine of the present embodiment comprises:

[0109] The inner cylinder 18 has a washing chamber for independently holding washing water;

[0110] The outer cylinder 19 is sleeved outside the inner cylinder 18;

[0111] The electromagnetic heating device is arranged on the side wall of the outer cylinder 19 and correspondingly heats the side wall of the inner cylinder 18 .

[0112] This embodiment provides a washing machine, the washing machine has an electromagnetic heating device, the side wall of the inner cylinder 18 is heated by the electromagnetic heating device, and the side wall of the inner cylinder 18 is heated by the electromagnetic heating device and then the heat is transferred to the washing machine in the inner cylinder 18. Water, realize the heating of washing water.

[0113] Electromagnetic heating is also called electromagnetic induction heating, that is, electromagnetic heating (foreign languag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com