Anti-scour method for coal roadway tunneling head-on anchor cable support

An anchor cable support and anchor cable technology, which is applied in earth-moving drilling, bolt installation, mining equipment and other directions, can solve the problems of head-on coal body impact on the tunnel face, single prevention method, and large influence on the tunneling speed. Achieve the effect of ensuring impact resistance, small coal wall disturbance, and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

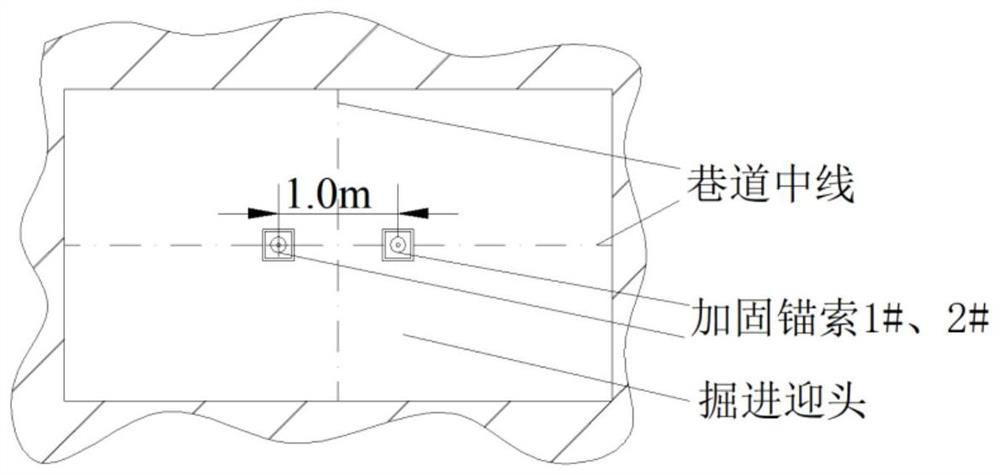

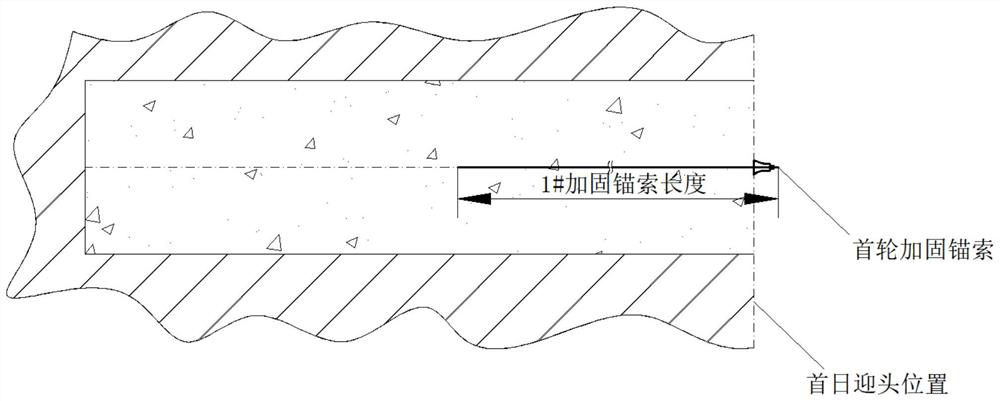

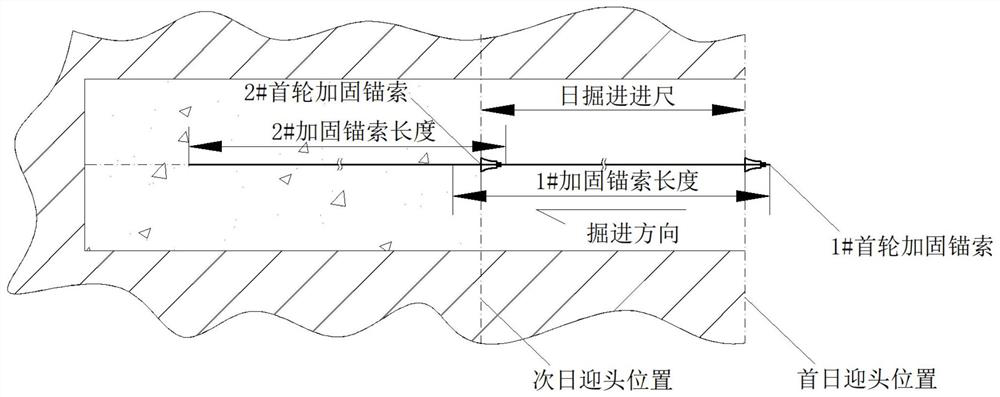

[0028] Embodiment: The working face of a certain mine has a strong impact risk, and the coal body impact frequently occurs during the coal roadway excavation; the present invention is used to strengthen the support and prevent the impact of the anchor cable, so as to figure 1 The above is described above, and the specific steps are:

[0029] Step 1. Before starting the excavation, the average coal thickness of the mined coal seam is measured to be 3m, the dip angle of the coal seam is nearly horizontal, and there is no obvious geological structure. The section of the roadway in this working face has a clear width of 4.6m, a clear height of 2.8m, and a section of the roadway of 12.88m. 2 , the average single-day excavation footage of the excavation face is 8m. According to the above geological conditions, coal seam thickness, roadway excavation elevation angle and single-day excavation footage, the reasonable construction parameters for reinforcement anchor cables are determine...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap