Large-deformation impedance-lifting anti-shearing anchor cable and construction method and working method thereof

A shearing-resistant, large-deformation technology, applied in the direction of earth drilling, bolt installation, mining equipment, etc., can solve the problems of anchor cable breakage, breakage, inconvenient processing, etc., achieve stable deformation and stress performance, and prevent energy absorption Column deflection, simple and easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

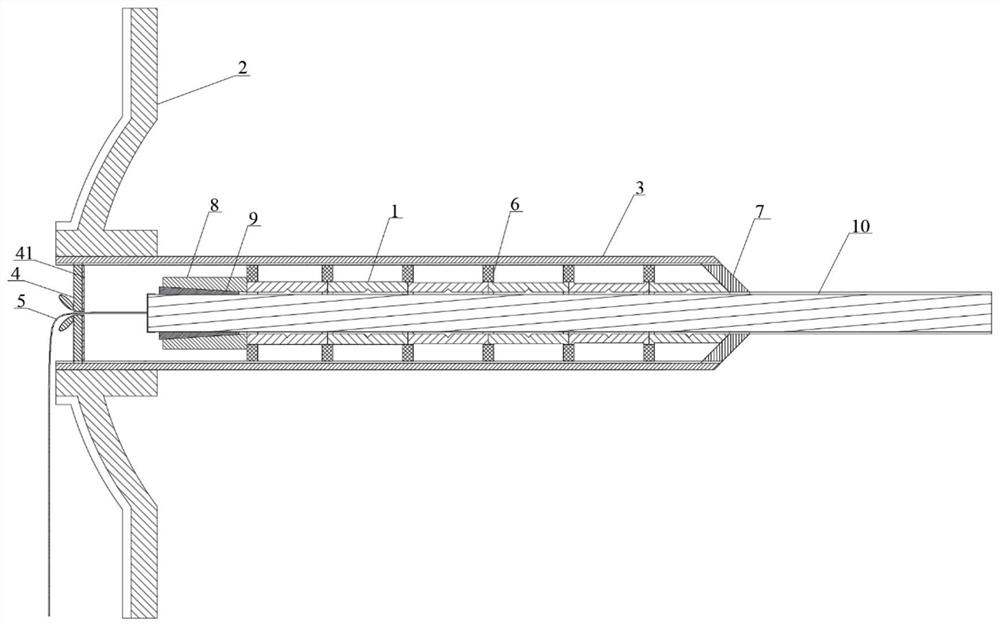

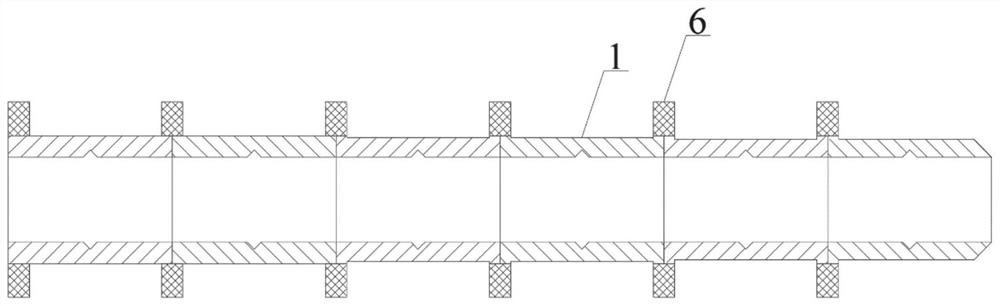

[0049] Such as figure 1 with figure 2 As shown, the large deformation rising impedance shearing anchor cable of the present invention includes an anchor cable 10, an energy-absorbing column 1 is provided at the end of the anchor cable 10, and an anti-shear sleeve 3 is provided on the outside of the energy-absorbing column 1 through an anti-deflection device. The energy-absorbing column 1 is arranged axially in the shear-resistant sleeve 3, the tail of the shear-resistant sleeve 3 is fixed with a ribbed tray 2, and the front end of the shear-resistant sleeve 3 is threaded with a tapered The limiting plate 7 of the structure;

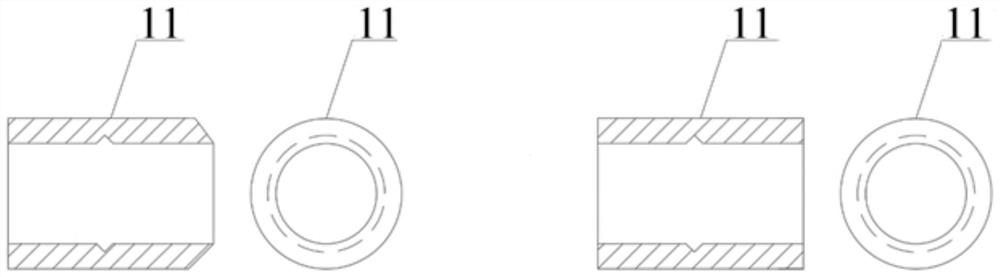

[0050] The anti-shear sleeve 3 is a hollow cylindrical tube, and the front end of the energy-absorbing column 1 is set in the limit plate 7, and the anti-shear sleeve 3 and the limit plate 7 are threaded. By adjusting the anti-shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com