Arc infolding rotating mechanism with invariable tangent point

A technology of rotating mechanism and arc, applied to the field of inner folding connecting shaft and arc inner folding rotating mechanism, can solve the problems of a large number of spare parts and inconvenient industrialized manufacturing, and achieve the effect of simple and effective structural design and easy industrialization implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

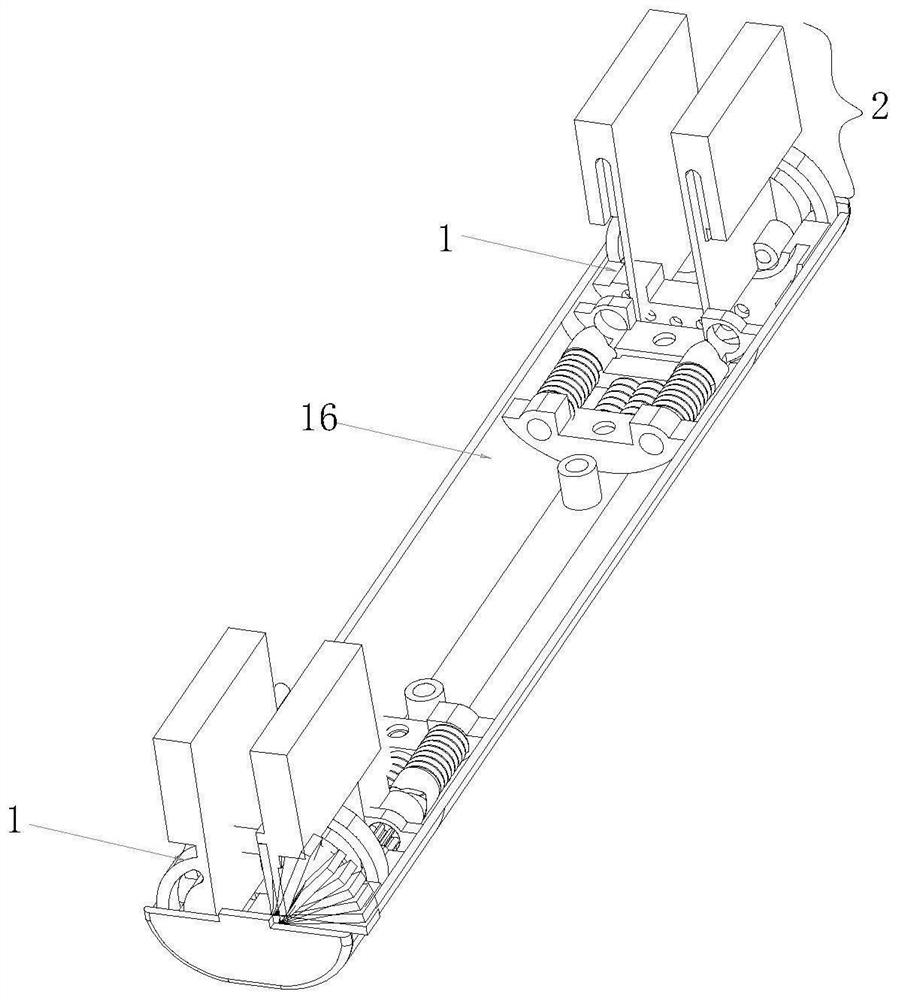

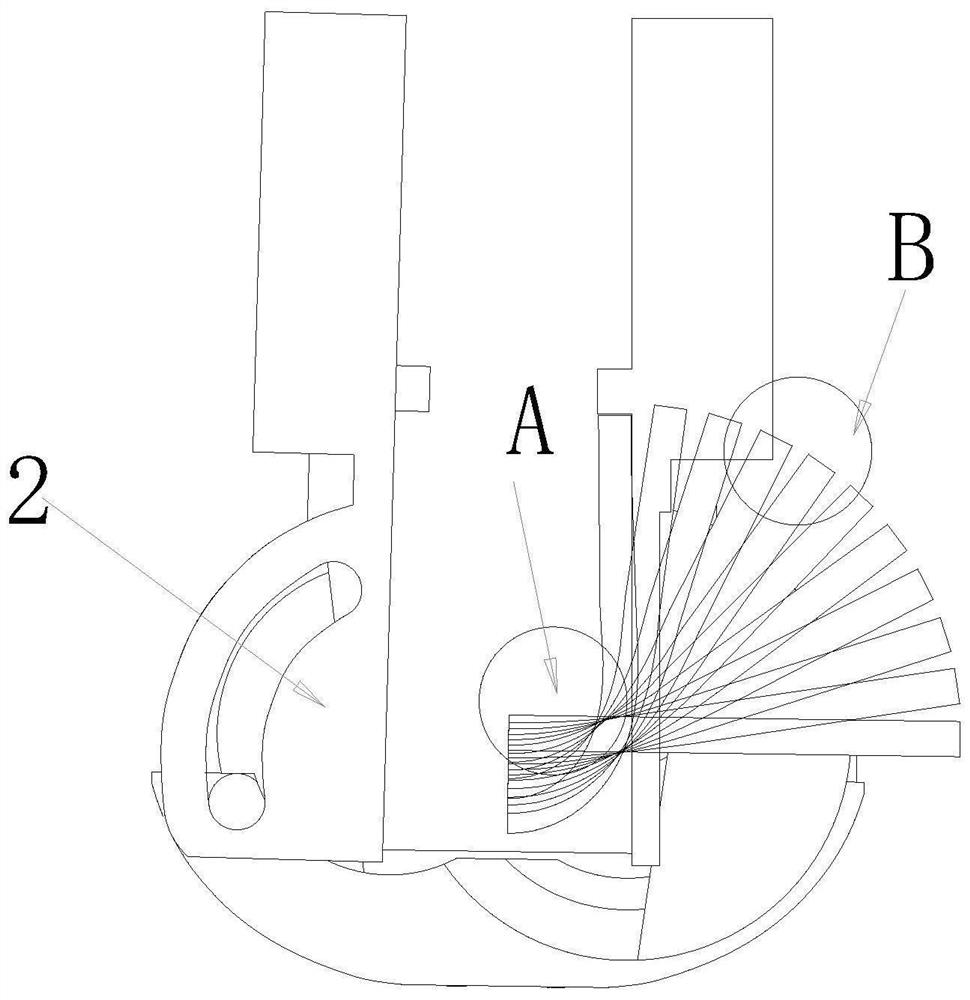

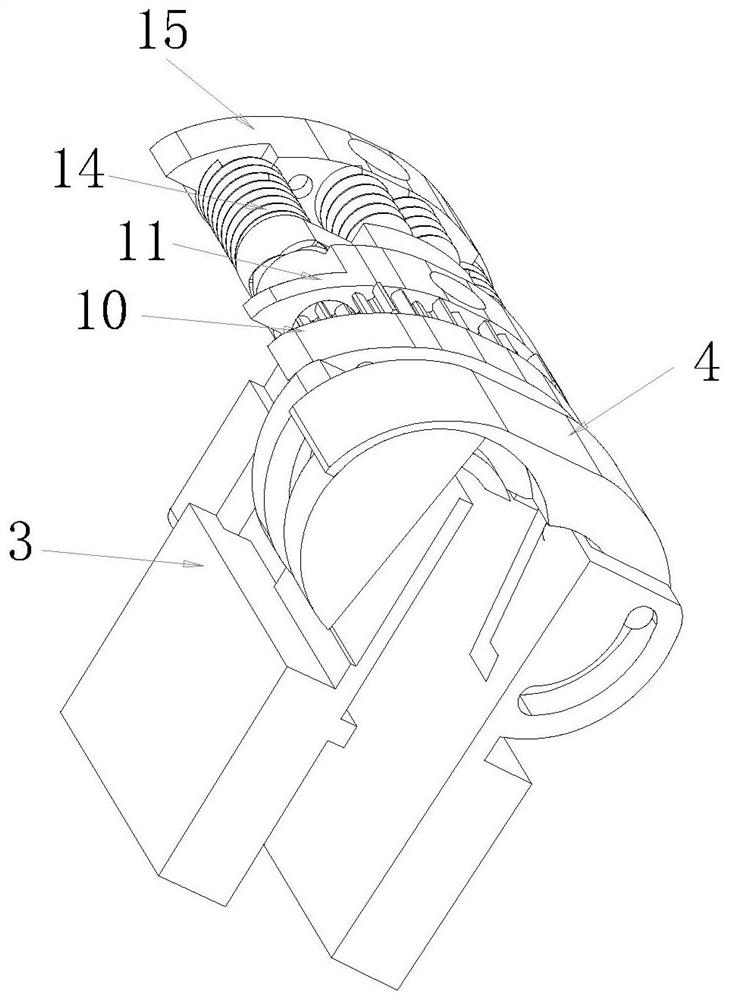

[0049] Such as Figure 9-14 As shown, the arc inward turning mechanism with no tangent point disclosed in this embodiment includes a rotating shaft 1, and the rotating shaft 1 includes a rotating mechanism 2, and the rotating mechanism 2 includes two sets of turrets 3 distributed laterally. Between the said turret 3, there are longitudinally distributed and rotatably connected circular arc groove movable blocks 4 and two groups of circular arc sliders 5. Slidingly connected arc chute 41, the arc slider 5 reciprocatingly slides in the arc chute 41 to realize U-shaped inward bending rotation with constant tangent point of 0°-180° motion track;

[0050] Between described turret 3 and described arc groove movable block 4, realize rotation through the sliding cooperation of sliding column 6 and curved groove 7; A rotating column 51 is provided, and the rotating connection between the rotating frame 3 and the arc slider 5 is realized through the rotating cooperation between the rot...

Embodiment 2

[0052] Such as Figure 15-20 As shown, the arc inward turning mechanism with no tangent point disclosed in this embodiment includes a rotating shaft 1, and the rotating shaft 1 includes a rotating mechanism 2, and the rotating mechanism 2 includes two sets of turrets 3 distributed laterally. Between the said turret 3, there are longitudinally distributed and rotatably connected circular arc groove movable blocks 4 and two groups of circular arc sliders 5. Slidingly connected arc chute 41, the arc slider 5 reciprocatingly slides in the arc chute 41 to realize U-shaped inward bending rotation with constant tangent point of 0°-180° motion track;

[0053]Between described turret 3 and described arc groove movable block 4, realize rotation through the sliding cooperation of sliding column 6 and curved groove 7; A rotating column 51 is provided, and the rotating connection between the rotating frame 3 and the arc slider 5 is realized through the rotating cooperation between the rot...

Embodiment 3

[0055] Such as Figure 20-26 As shown, the arc inward turning mechanism with no tangent point disclosed in this embodiment includes a rotating shaft 1, and the rotating shaft 1 includes a rotating mechanism 2, and the rotating mechanism 2 includes two sets of turrets 3 distributed laterally. Between the said turret 3, there are longitudinally distributed and rotatably connected circular arc groove movable blocks 4 and two groups of circular arc sliders 5. Slidingly connected arc chute 41, the arc slider 5 reciprocatingly slides in the arc chute 41 to realize U-shaped inward bending rotation with constant tangent point of 0°-180° motion track;

[0056] Between described turret 3 and described arc groove movable block 4, realize rotation through the sliding cooperation of sliding column 6 and curved groove 7; A rotating column 51 is provided, and the rotating connection between the rotating frame 3 and the arc slider 5 is realized through the rotating cooperation between the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com