Under-bed countercurrent ignition device of circulating fluidized bed boiler

A technology of circulating fluidized bed and ignition device, which is applied in the direction of fluidized bed combustion equipment, combustion ignition, and molten fuel burning, etc., can solve the problems of long air duct design, huge equipment weight, and increased boiler ignition fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention is described in further detail below with reference to accompanying drawing:

[0007] Structural description of the present invention is as follows:

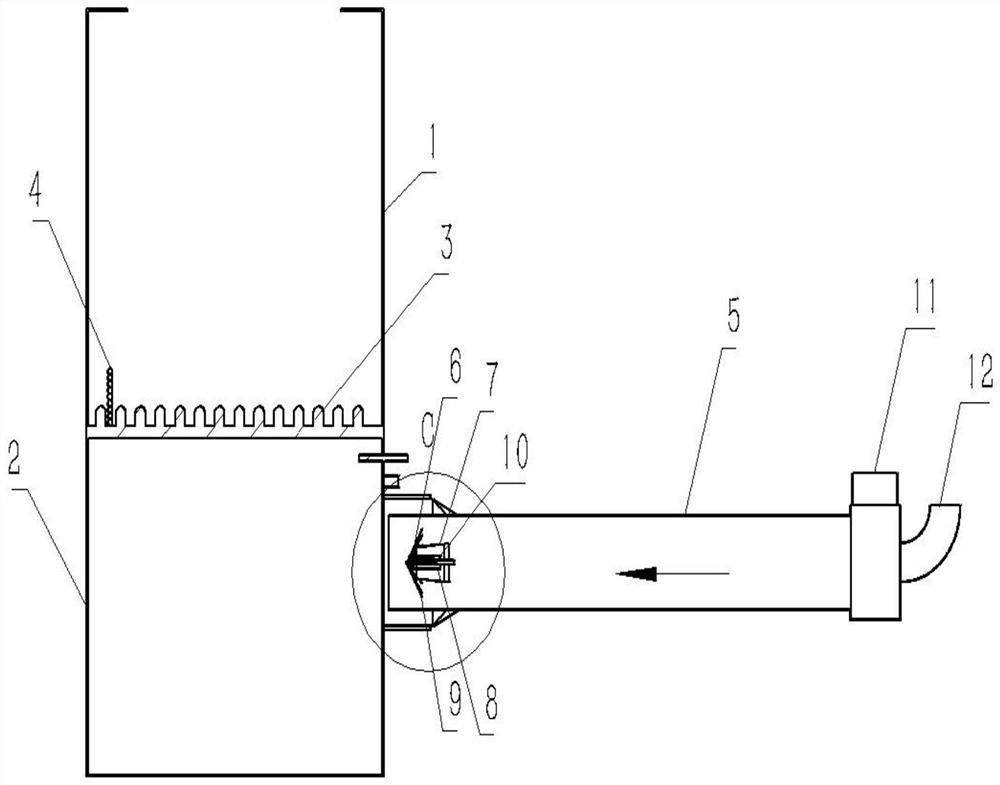

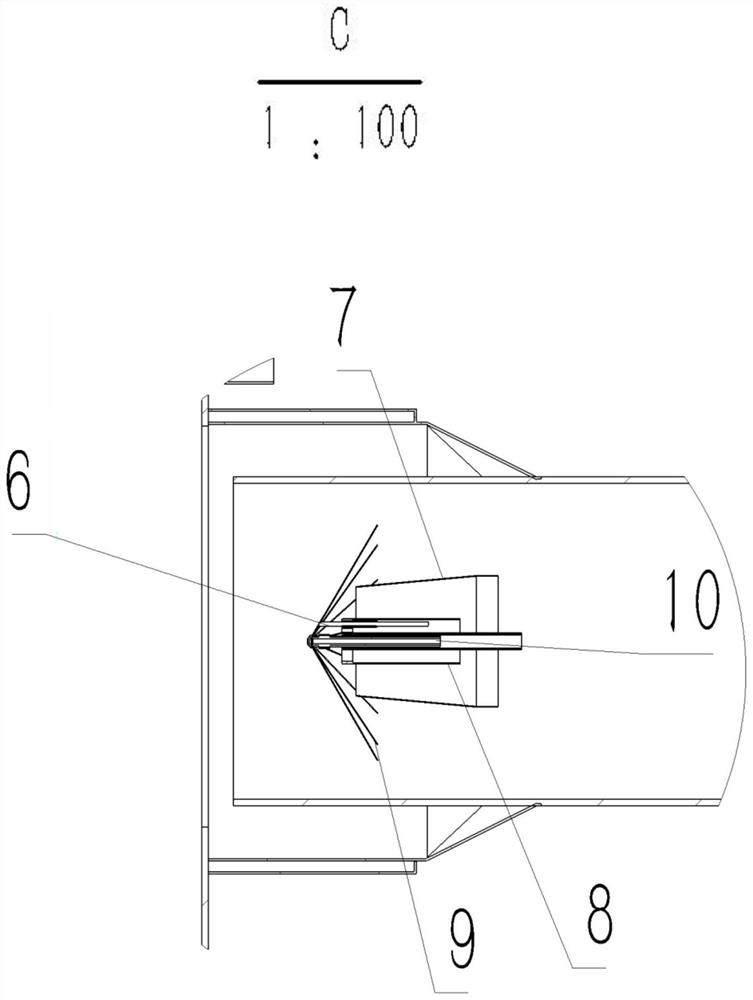

[0008] Refer to attached figure 1 , attached figure 2 As shown, the countercurrent ignition device under the circulating fluidized bed boiler mainly includes: a boiler, an ignition air duct and a countercurrent oil gun combined burner; the boiler mainly includes: a furnace 1, an air chamber 2, a fluidized bed body 3, Bed material 4; the ignition air duct includes: main air duct 5, square and round joints 13, combustion air inlets 11, 12; Fuel-saving and environment-friendly oil gun 10, ignition gun 6, flame stabilizer-oil gun conduit-inner air cylinder assembly 8 and flame jet 9.

[0009] Wherein the circulating fluidized bed boiler bed countercurrent ignition device includes: a boiler, the boiler mainly includes a furnace 1, an air chamber 2 and a fluidized bed bed body 3; the bed material 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com