Comprehensive quality forward and reverse tracing system in electronic manufacturing industry

A reverse traceability and manufacturing technology, applied in the direction of manufacturing computing systems, commerce, instruments, etc., can solve the problems of less positive and reverse traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

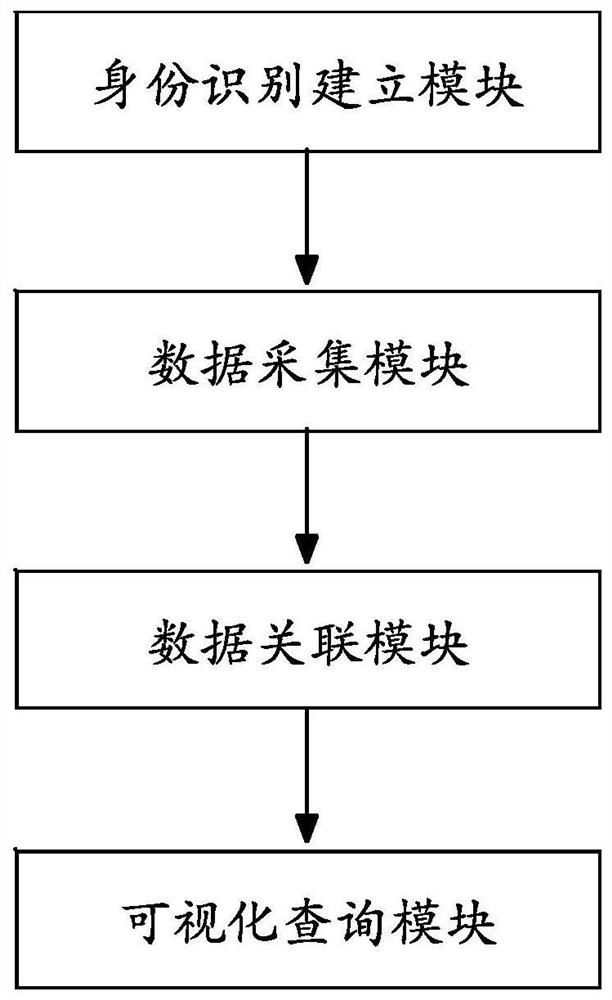

[0025] Such as figure 1 As shown, a total quality forward and reverse traceability system for electronics manufacturing industry, including:

[0026] The identification establishment module is used to establish corresponding identity information for each raw material, semi-finished product and finished product in the product production link of the electronic manufacturing industry. For example, the serial number SN (Serial Number, product serial number) of the finished product, the ID (Identity Document, identification number) of the raw material, and so on.

[0027] As preferably, the identity information of the raw materials established in the identity identification establishment module includes but is not limited to:

[0028] Identity information such as supplier code, raw material code, supplier production date, batch number, delivery time, quality inspection standard, quality inspection information, and quality inspection report.

[0029] Preferably, the identity infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com