Bearing ball counting visual detection system

A technology of visual detection and bearing balls, applied in calculation, image data processing, conveyor objects, etc., can solve the problems of high labor intensity, inability to fully guarantee the production quality of bearings, and low work efficiency, so as to ensure production quality and realize full The effect of automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

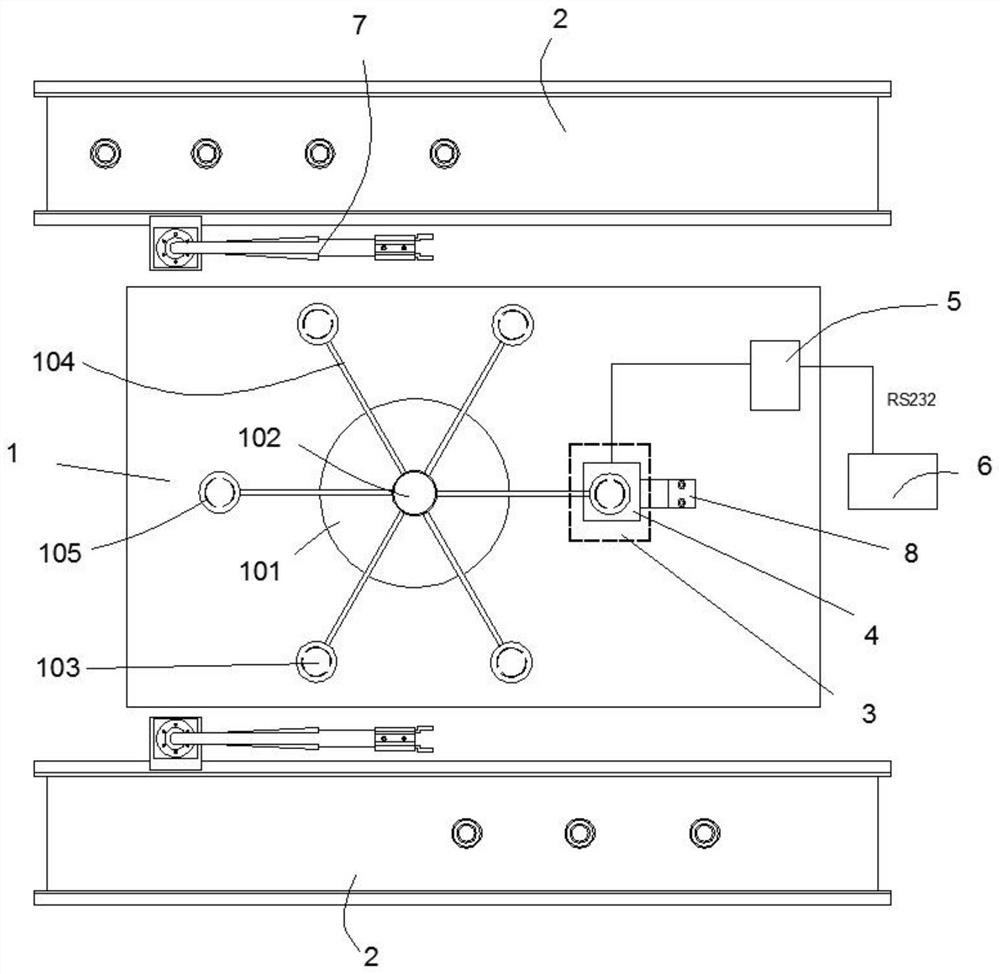

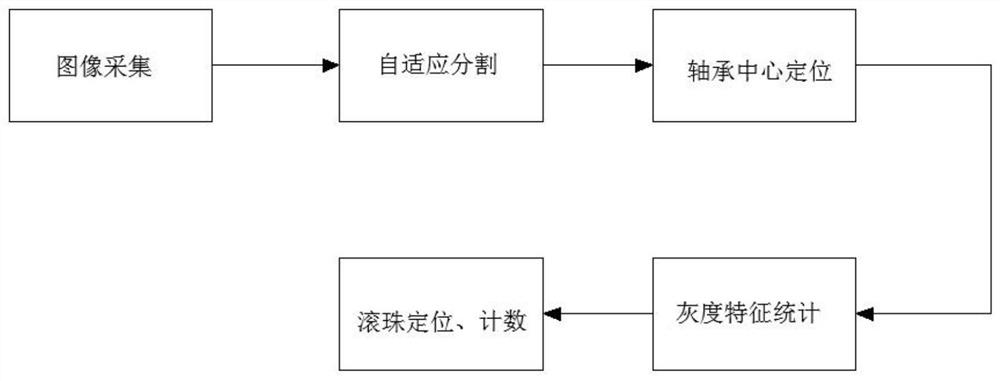

[0029] A kind of bearing ball counting visual detection system of the present embodiment, refer to figure 1 : Including a circular loading structure and a visual optical system. The circular loading structure includes a rotating structure 1 and a belt conveying structure. The belt conveying structure is symmetrically arranged on both sides of the rotating structure 1. The visual optical system includes a light source 3 and a CCD lens. 4. The image acquisition card 5 and the computer 6, the light source 3 and the CCD lens 4 are symmetrically installed on the upper and lower parts of the rotating structure 1, the image acquisition card 5 processes the image collected by the CCD lens 4 and uploads it to the computer 6, and the computer 6 passes the built-in algorithm Counting and testing of bearing balls.

[0030] The rotating structure 1 includes a base 101, a support rod 102 and a stage 103. The support rod 102 is divided into an upper strut and a lower strut. A stepping motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com