Bearing watertight connector

A technology of connector and heavy water, which is applied in the direction of connection, two-part connection device, parts of connection device, etc., can solve the problems of reducing connection reliability, failure, affecting signal transmission, etc., and achieve the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

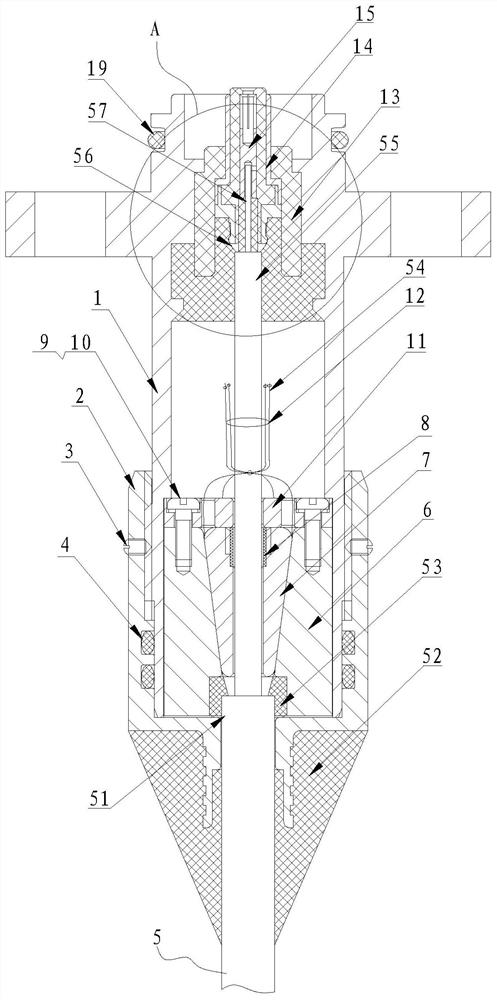

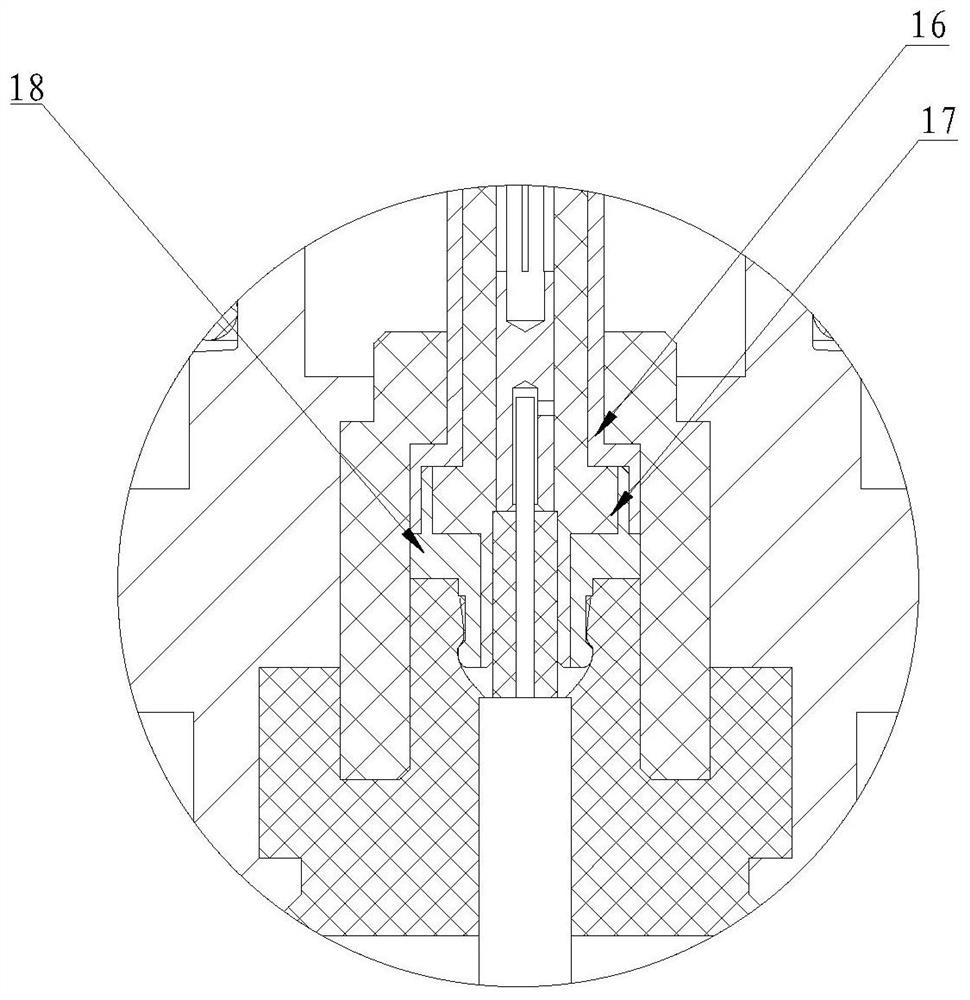

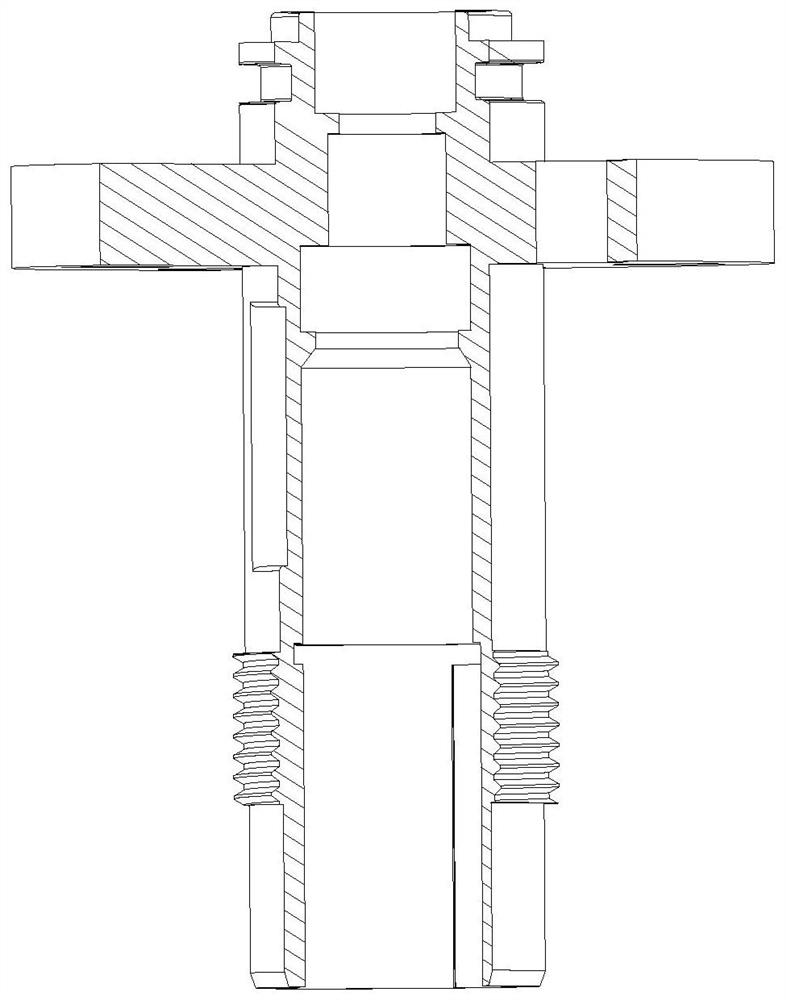

[0037] as attached Figure 1-2 As shown, a cable tensile connection structure mainly includes an intermediate sleeve 6, a central sleeve 7, mounting screws 9, spring washers 10 and a pressure plate 11,

[0038] Both sides of the outer circular surface of the intermediate sleeve 6 are provided with anti-rotation flats, and the front end surface is provided with threaded holes uniformly distributed in the circumferential direction for the connection of the pressure plate and through holes for injecting glue. The inner hole is composed of a tapered hole connected with a cylindrical hole. Among them, the tapered hole is located at the front end, and the cylindrical hole is located at the rear end;

[0039] The outside of the central sleeve 7 is tapered, the size is adapted to the inner hole of the intermediate sleeve 6, and inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com