An explosion-proof power junction box

An explosion-proof power supply and junction box technology, applied in electrical components, separation methods, dispersed particle separation, etc., can solve the problems of explosion at joints, inconvenient installation and disassembly of junction boxes, safety accidents, etc., and achieve convenient installation and disassembly. The effect of reducing work intensity and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

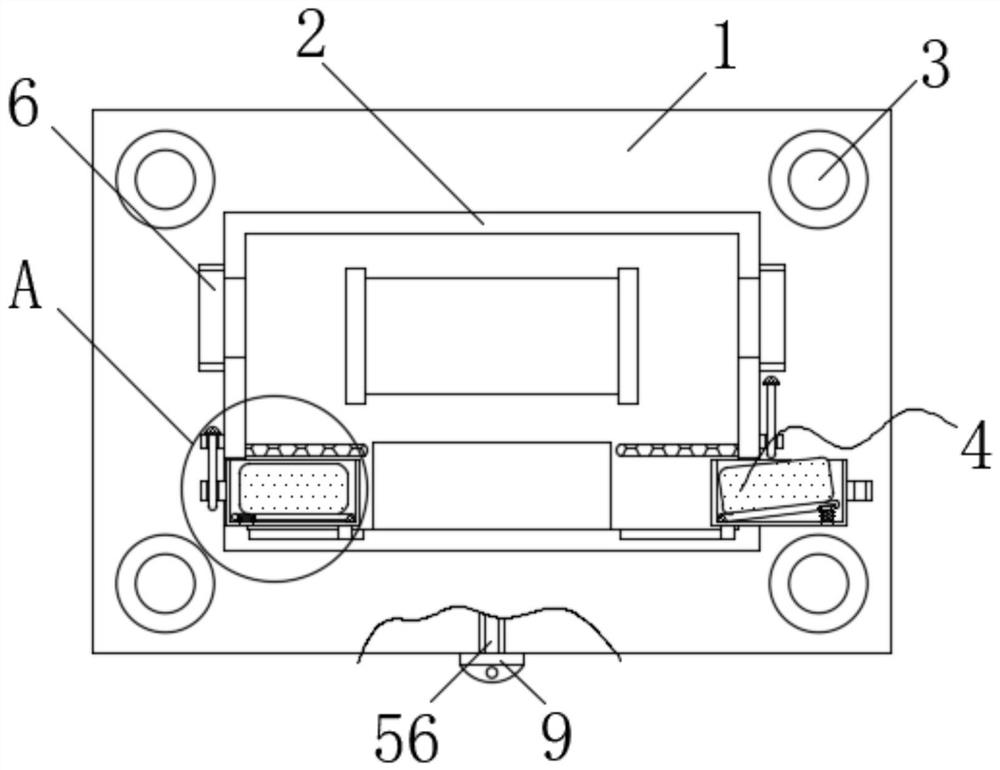

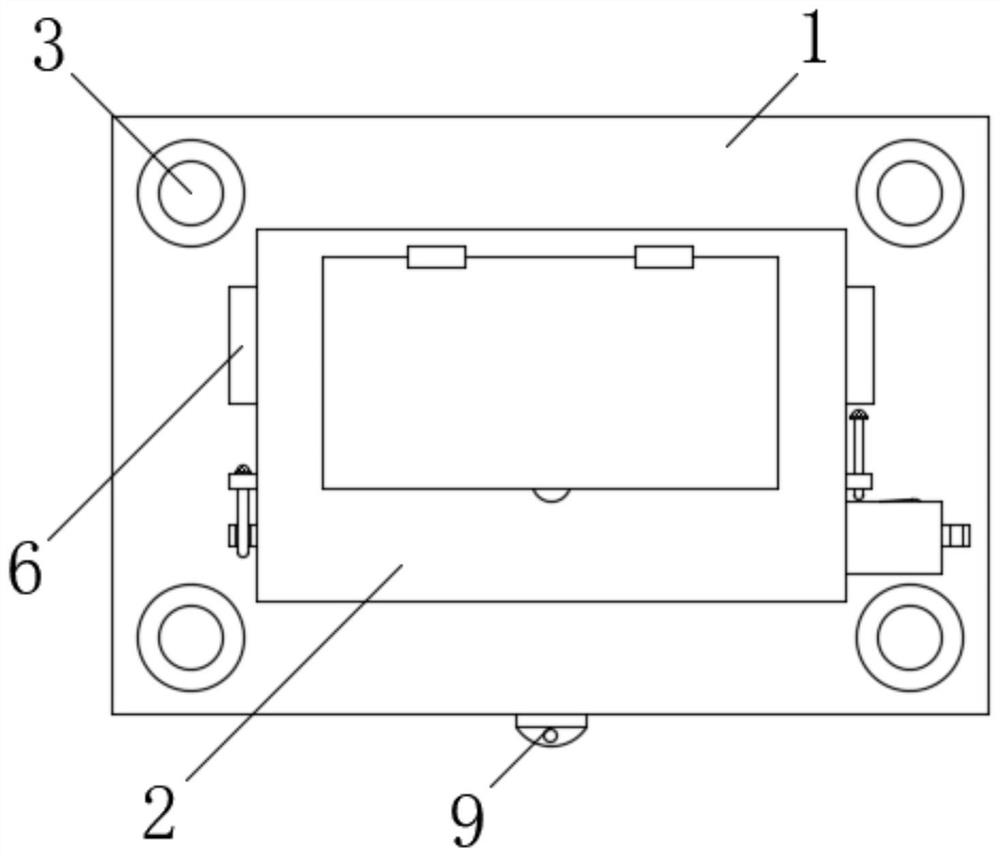

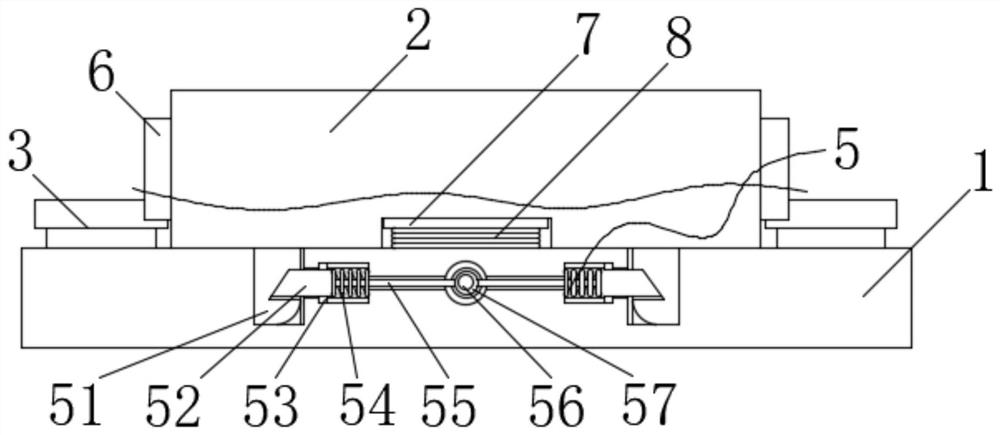

[0028] Such as Figure 1-4 As shown, the present invention provides an explosion-proof power supply junction box, including: a mounting plate 1, a junction box body 2, a replacement mechanism 4 and a buckle mechanism 5; the front of the mounting plate 1 is detachably connected to the junction box body 2, so The front of the mounting plate 1 is provided with two left-right symmetrical grooves, and a buckle mechanism 5 is provided in the two grooves. The left and right sides of the junction box body 2 are provided with placement holes, and the placement holes are provided with Replacement mechanism 4; the buckle mechanism 5 includes a mounting block 51, a clamping block 52, a second slider 53, a third spring 54 and a wire 55; wherein, the back of the junction box body 2 is fixedly connected with two mounting blocks 51. The two mounting blocks 51 are respectively arranged in the two grooves, and the adjacent surfaces of the inner walls of the two grooves are provided with a first...

Embodiment 2

[0038] Such as image 3 As shown, this embodiment provides an explosion-proof power supply junction box. The difference from Embodiment 1 is that a first spring 8 is fixedly connected to the front of the mounting plate 1, and a pressure plate 7 is fixedly connected to the other end of the first spring 8. , the front of the pressing plate 7 is attached to the back of the junction box body 2 .

[0039] In practical application, when workers disassemble the junction box body 2, when the two blocks 52 no longer limit the slot, the junction box body 2 will automatically pop up under the action of the resilience of the first spring 8, which is convenient The work of the workers has been improved, and the work efficiency of the workers has been increased.

Embodiment 3

[0041] Such as image 3 As shown, this embodiment provides an explosion-proof power supply junction box. The difference from Embodiment 1 is that the side of the installation block 51 close to the block 52 is arranged in an arc shape, and the faces away from the two blocks 52 are evenly spaced. Set on a slope.

[0042] In practical applications, during installation, workers only need to directly align the installation block 51 with the groove, and press it downwards, and the two clamping blocks 52 will approach each other under the action of the inclined surface, so that workers When installing the junction box, there is no need to twist the torsion ring 9, only need to press directly to fix it, which facilitates the installation work of the workers and reduces the work intensity of the workers.

[0043] Working principle, workers can install the installation plate 1 on the place where the junction box body 2 is needed through the installation seat 3, and then place the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com