Wire embedding device convenient for fixing assembly type wire embedding pipe

A prefabricated, wire-pipe technology, applied in electrical components and other directions, can solve problems such as the fixed connection of buried wire pipes, increasing the risk of electricity consumption, and the inability to effectively seal the connection between wire boxes and buried wire pipes. The danger of electricity consumption and the effect of ensuring the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

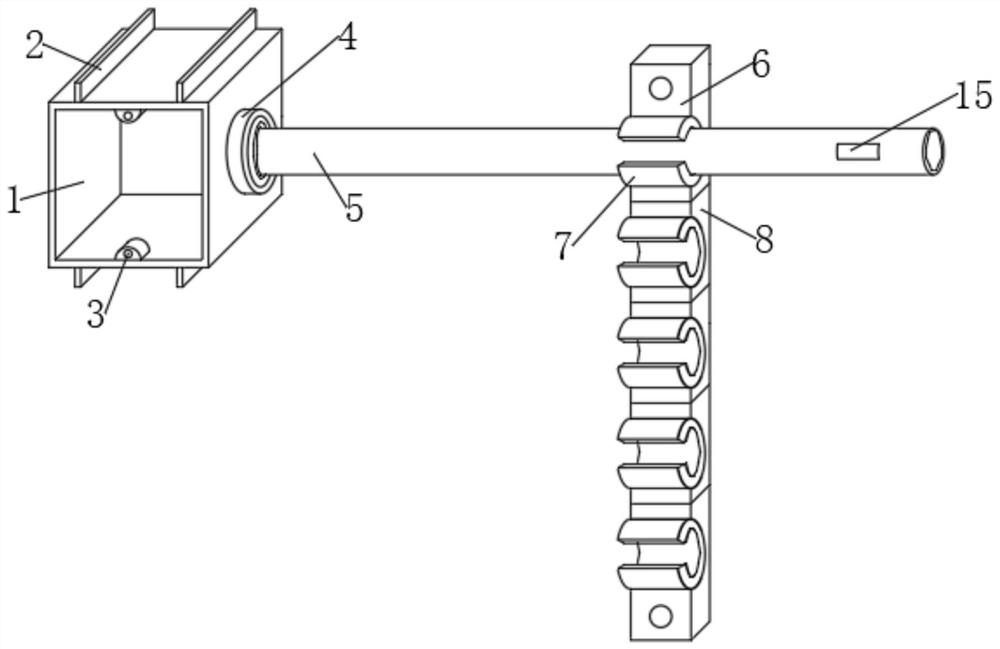

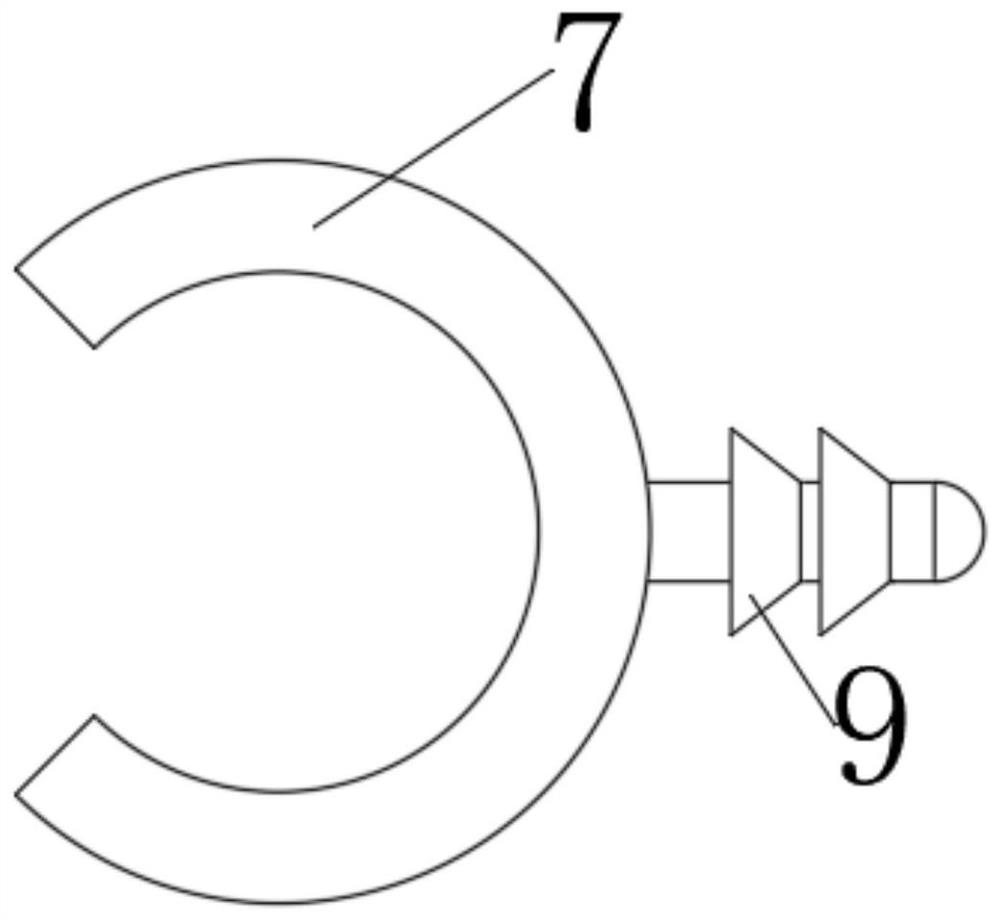

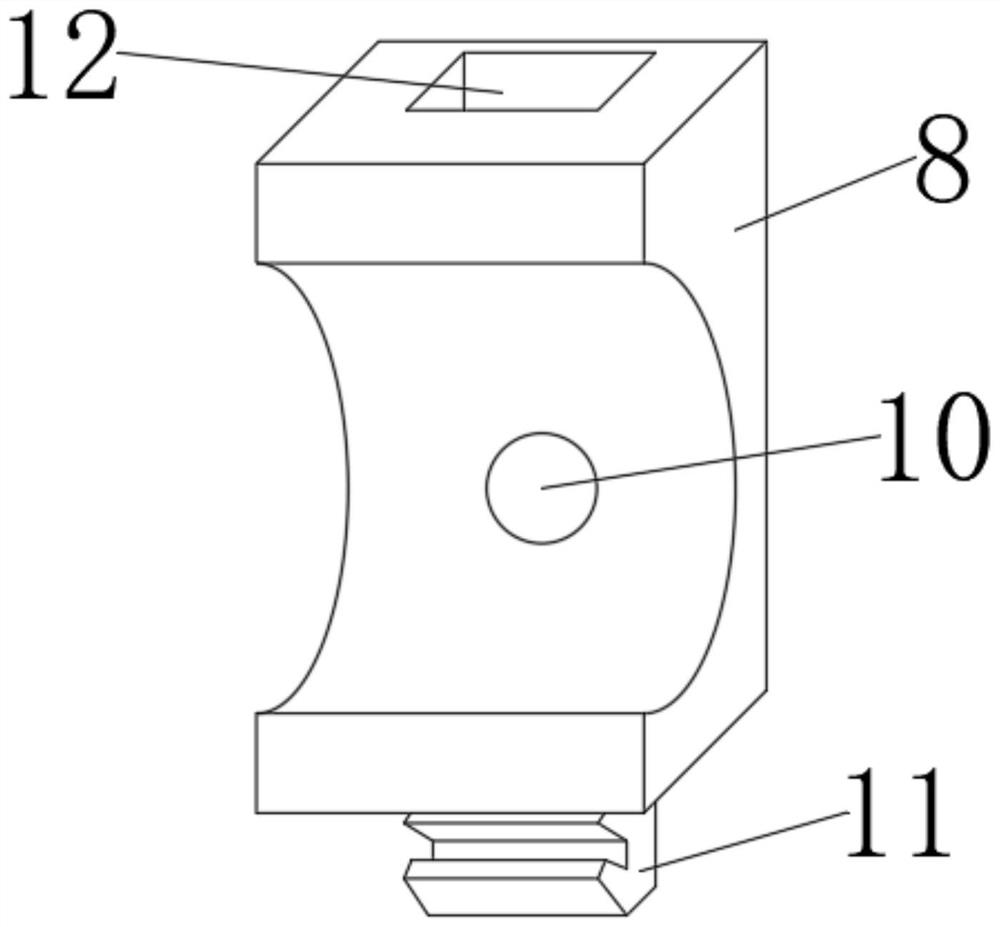

[0034] Such as Figure 1-Figure 5 As shown, a thread embedding device that facilitates the fixing of an assembled thread embedding tube includes a wire box 1, a fastening ring 4 and a thread embedding pipe 5. A fastening ring 4 is inserted in the center of one side of the line box 1, and a fastening ring 4 The inner side of the end away from the wire box 1 is plugged with the embedding tube 5, and the inner card slot of the clamping ring 4 is connected with a clamping ring 13. In addition, the symmetrical side of the embedding box 1 is integrally formed with a positioning rib 2, and the embedding tube 5 is far away from the card. An identification block 15 is provided on the outer side of one end of the fixing ring 4, a fireproof coating 14 is coated on the inner wall of the embedding pipe 5, a clamping pipe ring 7 is provided on the outside of the embedding pipe 5, and an assembly block 8 is provided on the side away from the opening of the clamping pipe ring 7 , the card tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com