BIM-based subway machine room equipment remote monitoring and maintenance system and method

A remote monitoring and maintenance system technology, applied in the direction of services, transmission systems, and signal transmission systems based on specific environments, can solve problems such as staying and failing to meet the dynamic needs of 3D visualization, and reduce labor costs and equipment failures. Timely and inappropriate handling of economic losses and casualties, and the effect of improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with embodiment.

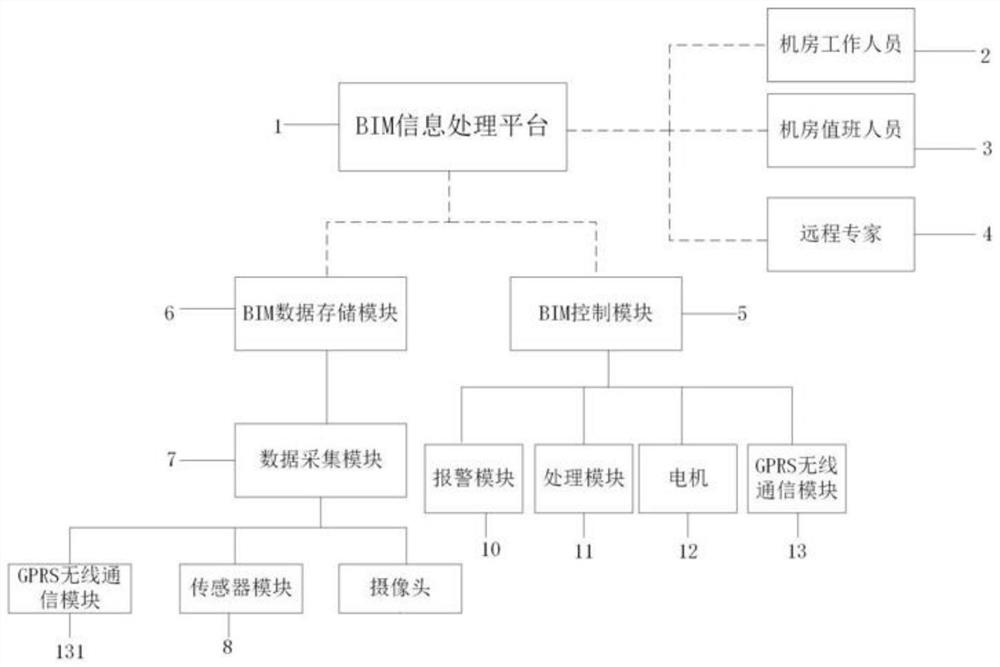

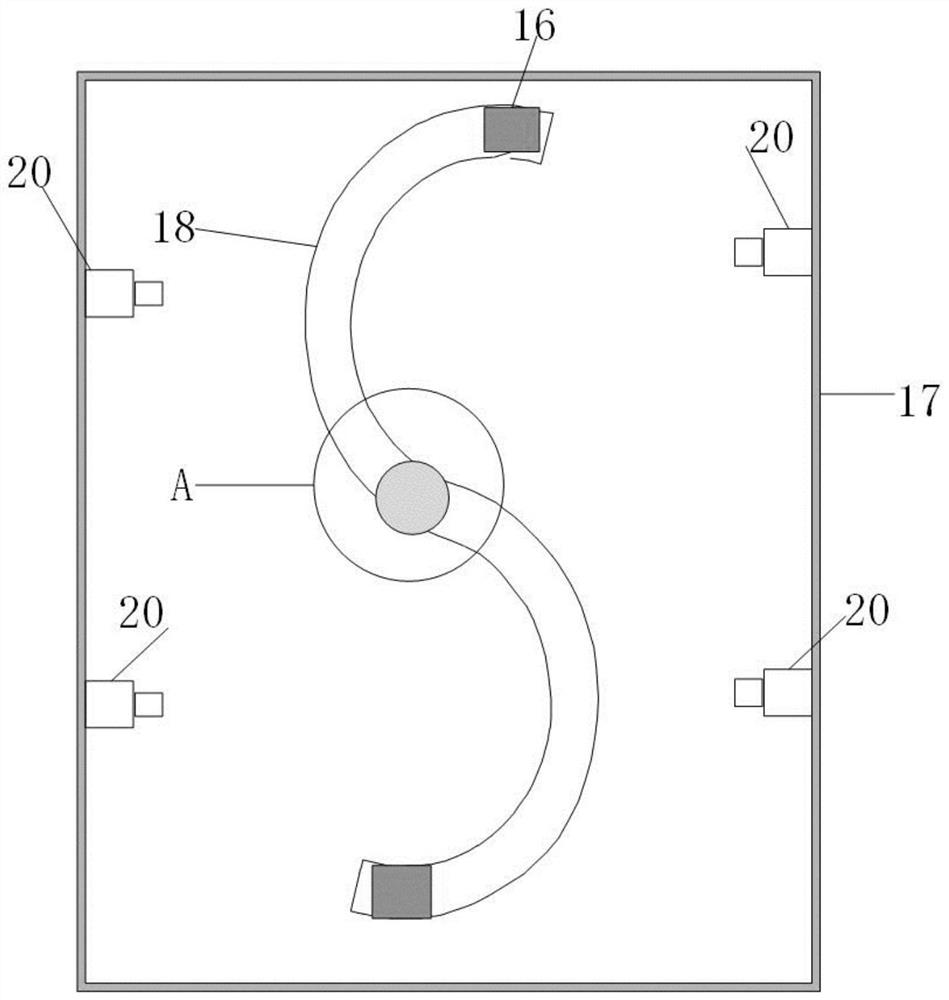

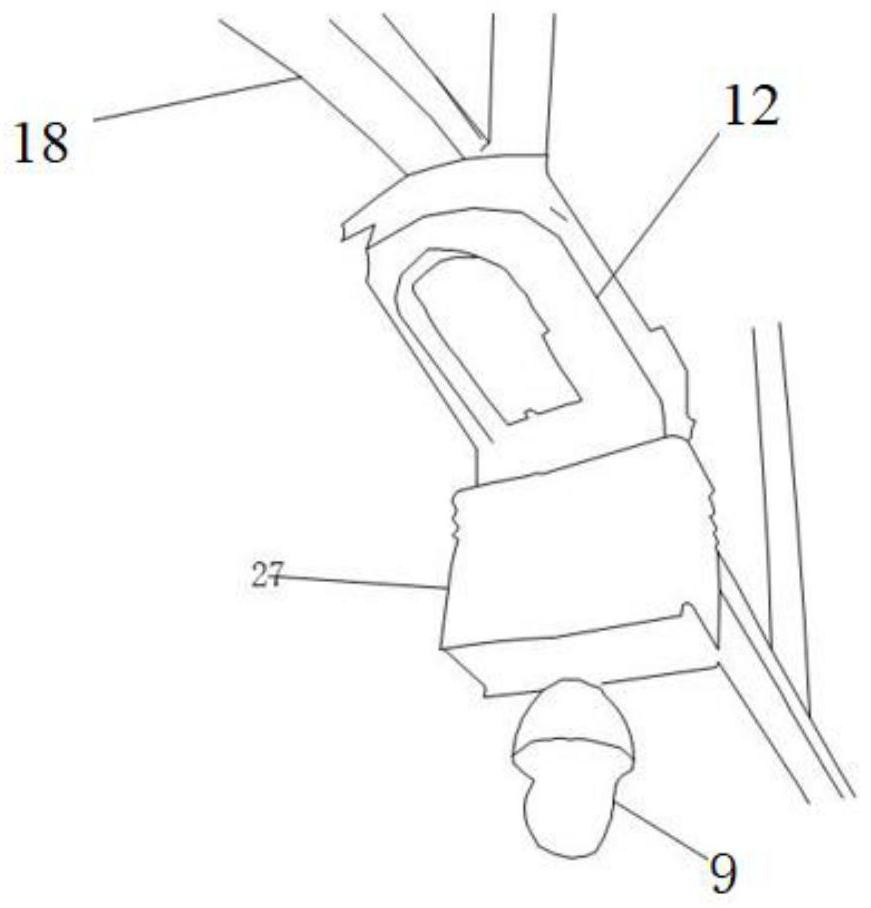

[0033] Such as Figure 1-Figure 4 Shown: A BIM-based remote monitoring and maintenance system for subway machine room equipment, see attached figure 1 , including a BIM information processing platform 1, a BIM data storage module 6, and a BIM control module 5 connected in sequence. The BIM information processing platform 1 is used to store the BIM three-dimensional model of the subway machine room 17 . The BIM data storage module 6 transmits the monitoring screen and the data collected by the sensor module 7 to the BIM information processing platform 1 through the GPRS wireless communication module 131 . The sensor module 8 and the camera 9 monitor the equipment information and emergencies in the computer room 17 in real time. The BIM control module 5 controls the various devices in the machine room 17 according to the BIM three-dimensional model of the subway machine room up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com