Automatic feed feeding system

A technology of automatic feeding and feed, applied in the field of breeding machinery, can solve the problems of unbalanced feed weight, high labor cost, threat to the growth and health of pigs, etc., and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

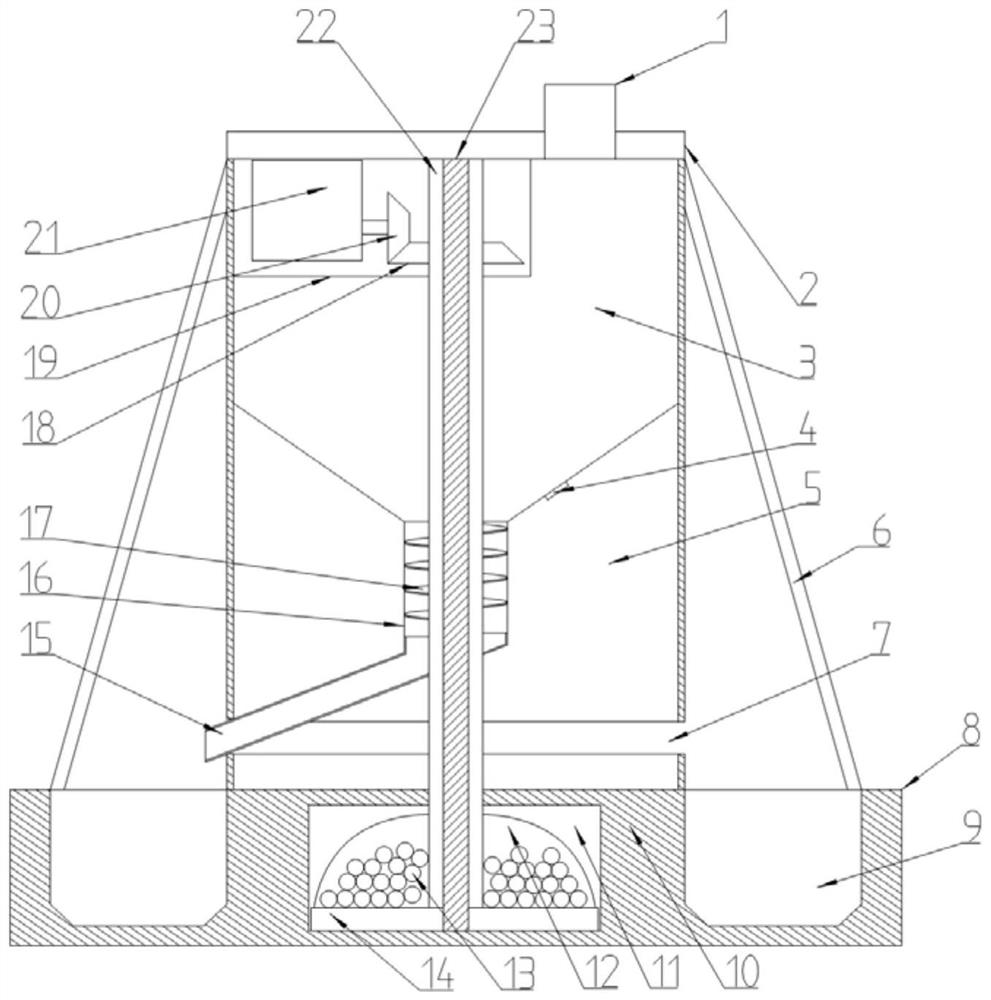

[0034] An automatic feed feeding system includes a control system and a feed feeding device. Feeding device basically as attached figure 1 As shown, it includes a feed pan 8 and a box body 2, and three support rods 6 are arranged between the feed pan 8 and the box body 2 and are distributed in an equilateral triangle. The feed tray 8 is provided with an annular trough 9, and the center of the feed tray 8 is a platform 10 in the shape of a round table, and the casing 2 is fixed on the platform 10.

[0035] The box body 2 includes a storage bin 3 and a discharge bin 5 . The top of the storage bin 3 is provided with a feed port 1 .

[0036]The storage bin 3 is provided with a transmission assembly, the transmission assembly includes a support column, a hollow rotating shaft 22 and a motor 21 drive unit, the upper end of the support column is fixedly connected with the center of the inner top surface of the storage bin 3, and the hollow rotating shaft 22 is sleeved on the Outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com