The installation method of the translational crane on the ship

An installation method and translation crane technology, applied in ship construction, ship design, ship parts, etc., can solve problems such as high risk and slow construction progress, shorten the construction period, reduce labor costs, and avoid underwater debugging workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

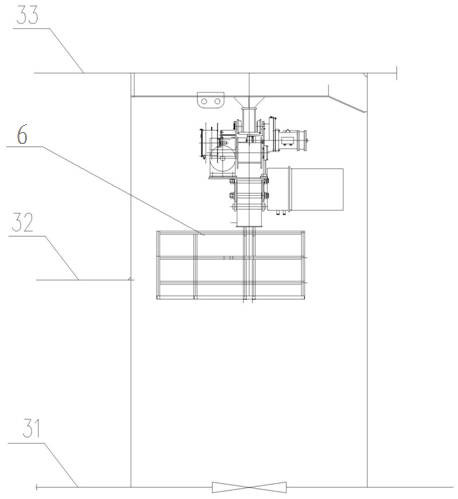

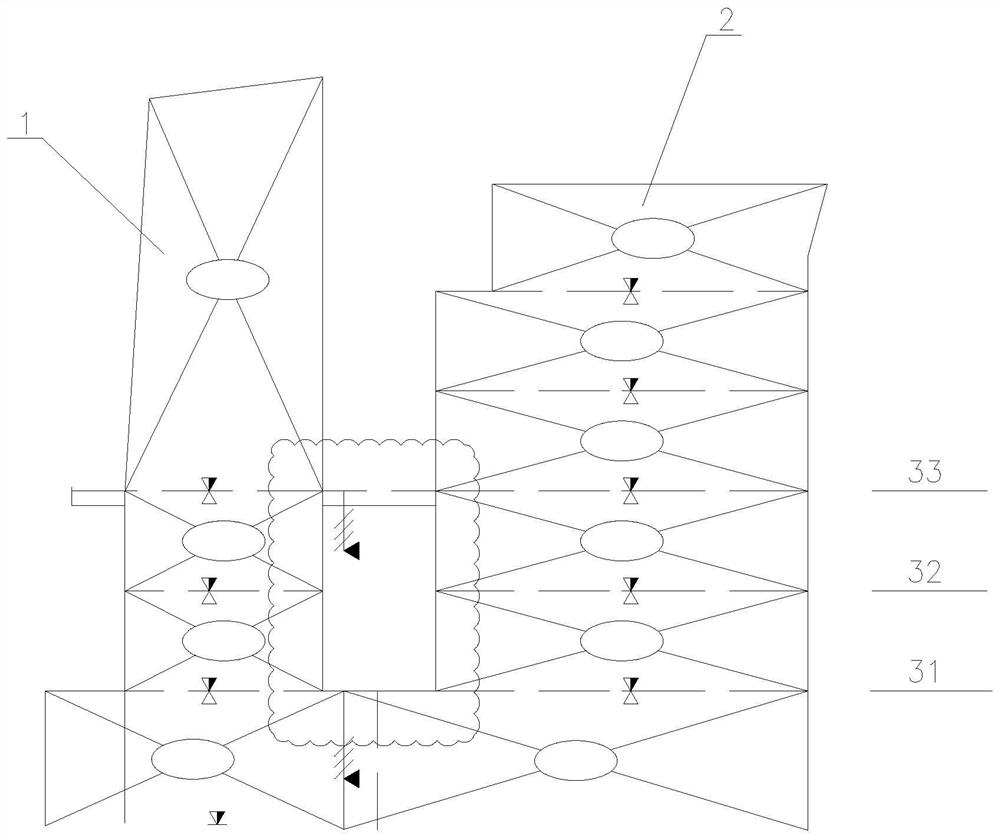

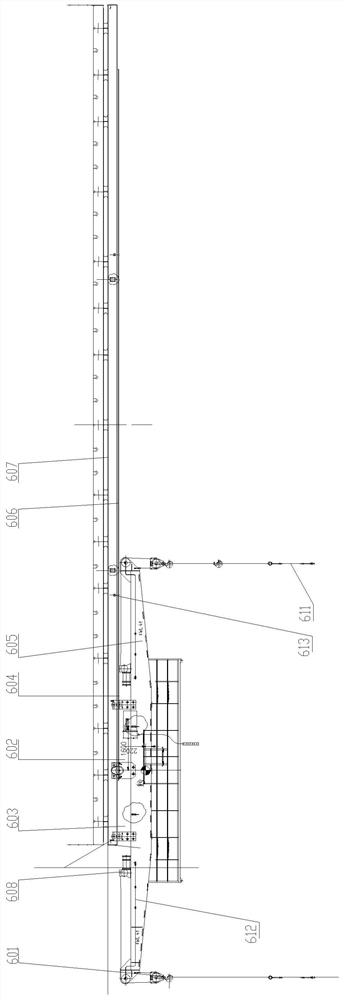

[0047] The translational crane is one of the important equipment of the bulk carrier. The company's 82000T series bulk carrier realizes the installation at the berth stage by moving the process forward, which further shortens the berth cycle.

[0048] Formulate the schedule delivery plan for the key equipment of the present invention, the translational crane, and advance the original underwater stage installation demand time to the berth stage from 42#82000. For the installation project of the translational crane stage, the main operation process and cycle management are as follows:

[0049] 1. The translational crane beam and related equipment accessories are required to come to the factory during the construction of the general group, and the actual arrival at the factory is March 5, 2020;

[0050] 2. On March 15, the initial installation and positioning of the translational crane girder on the C deck of the upper construction general group stage;

[0051] 3. On March 25, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com