Textile machinery for stable latitudes of latitudes

A textile machinery and stable technology, applied in the direction of looms, textiles, textiles and papermaking, etc., can solve the problems of weft knotting and pulling, failure to guide weft, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

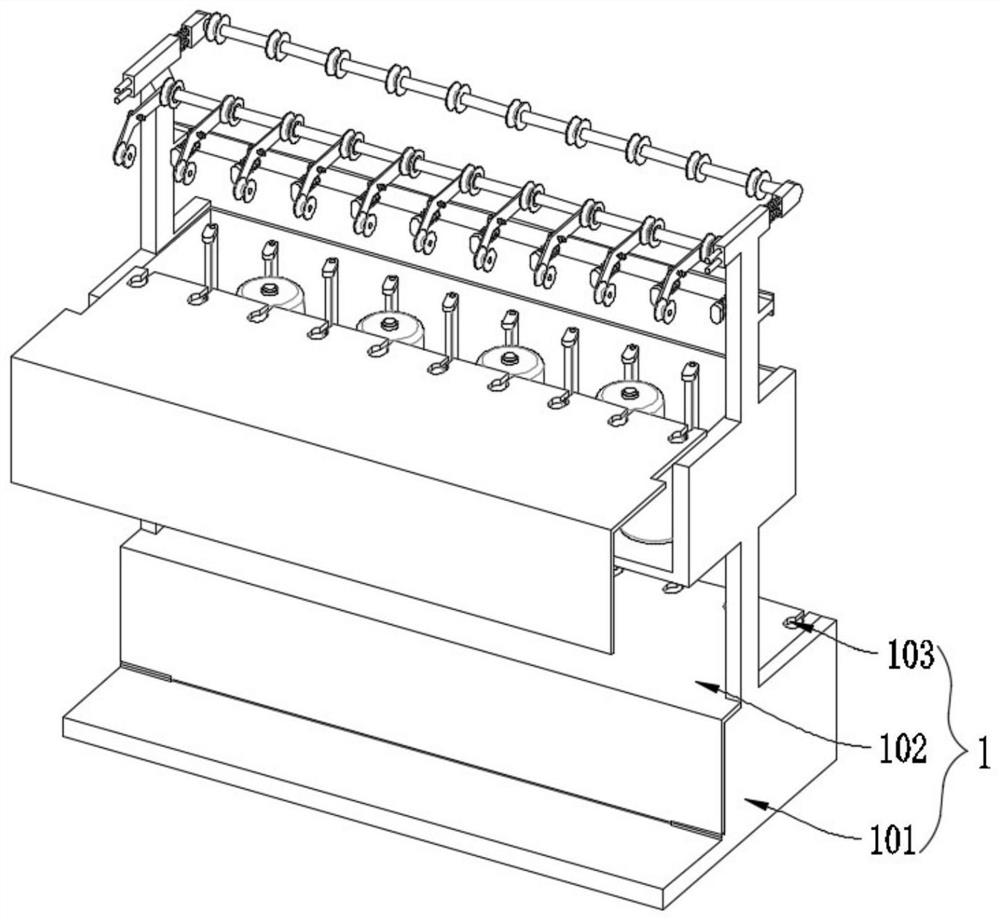

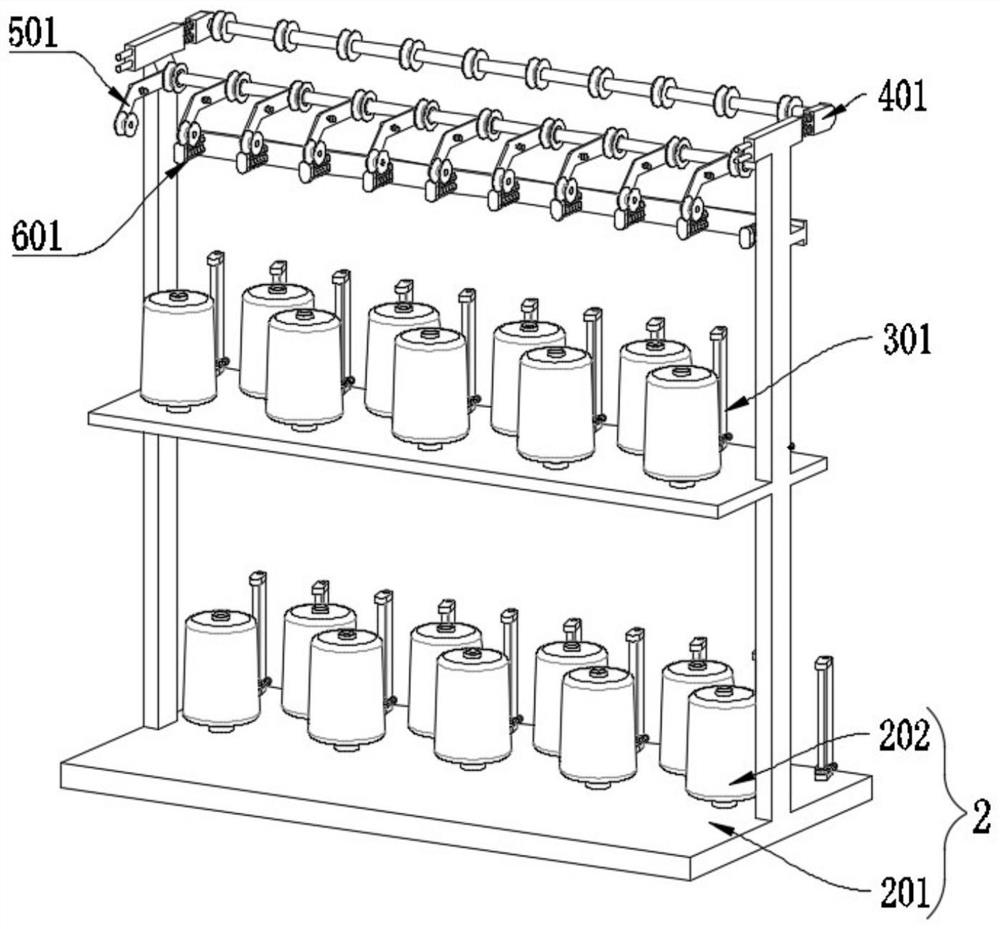

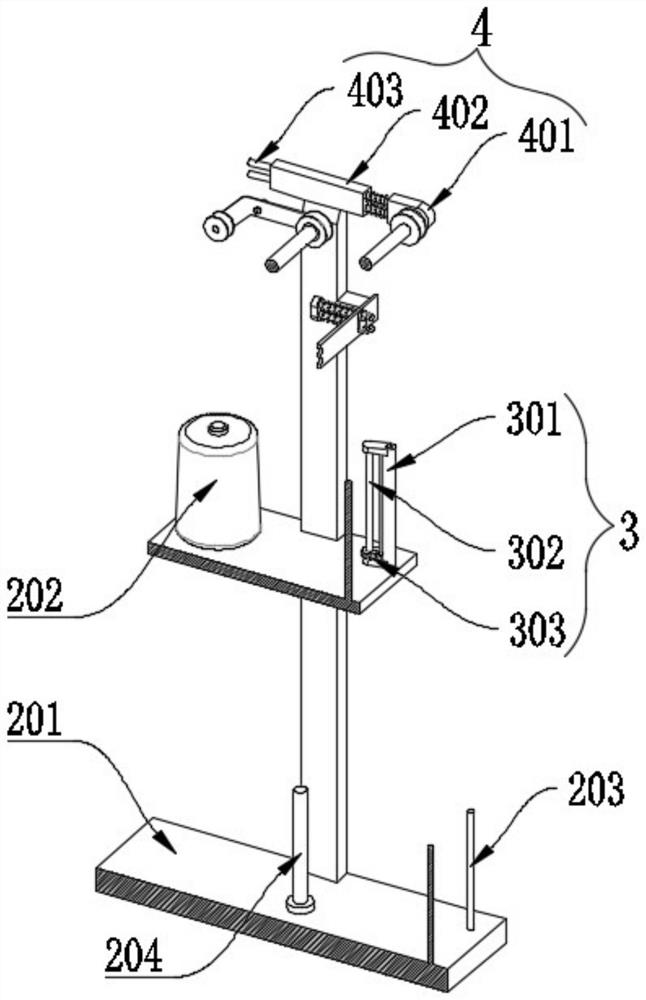

[0033] as attached figure 1 to the attached Figure 7 shown:

[0034] The present invention provides a stable weft insertion box for textile machinery, comprising a shell structure 1; the shell structure 1 is fixedly mounted on an installation structure 2; a guide structure 3 is rotatably mounted on the mounting structure 2; Structure 4; the lower end of the top frame structure 4 is hingedly installed with an adjustment structure 5; the upper end of the installation structure 2 is installed with an auxiliary structure 6; The box shell 102 is installed. The overall structure of the box shell 102 is L-shaped. The end of the box shell 102 is provided with a wire outlet 103, and the position of the wire outlet 103 is equipped with a magnetic block. The installation frame 101 is set at the middle height. The box shell 102 is slidingly installed, and the upper box shell 102 is also equipped with a magnetic block, the box shell 102 at the bottom of the mounting frame 101 is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com