An easy-to-install road guardrail

A technology for guardrails and roads, which is applied in the direction of roads, roads, road safety devices, etc. It can solve the problems of low utilization rate of carriages, affecting the repair efficiency of guardrails, and large size of guardrails, so as to improve installation stability and facilitate quick installation and disassembly Operation, improve the effect of overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

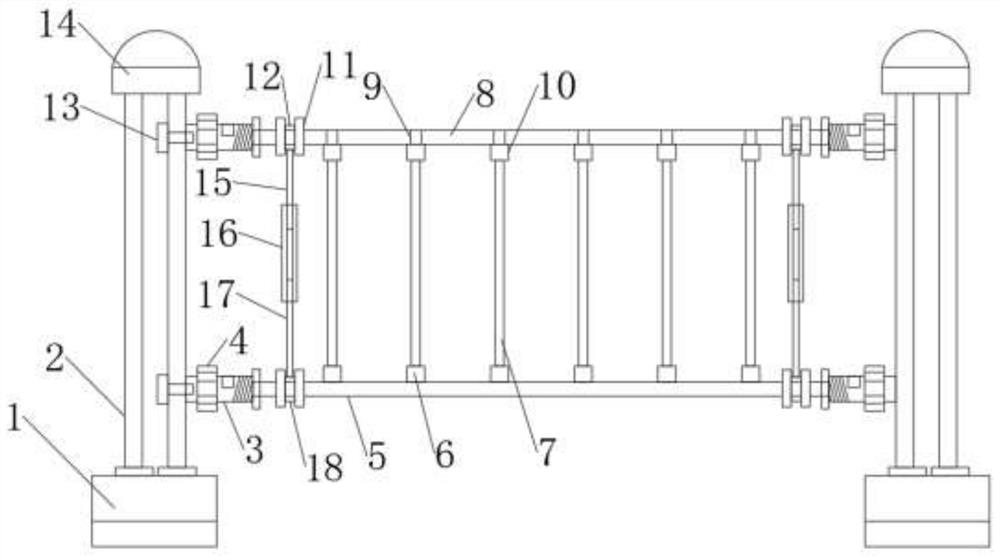

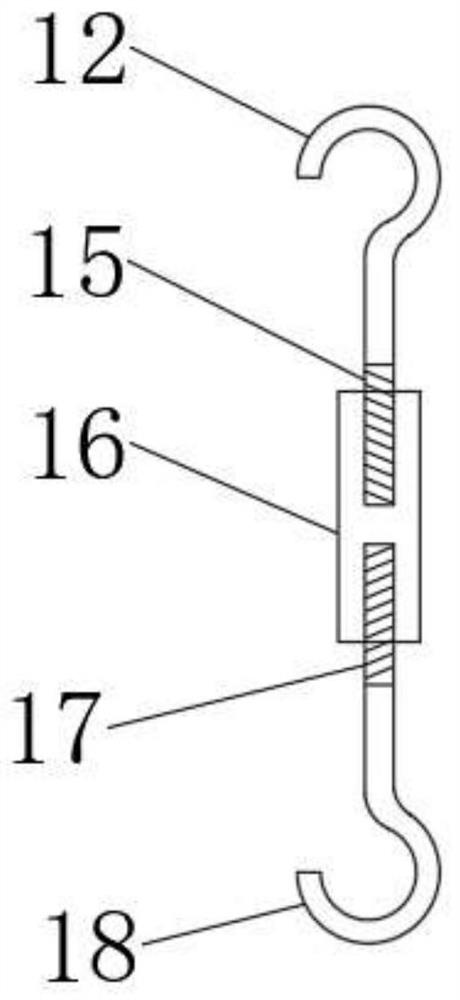

[0027] Such as Figure 1-6 As shown, a road guardrail that is easy to install includes a base 1, and the base 1 is provided with a column 2, and the column 2 is inserted on the base 1, and the column 2 is provided with a mounting sleeve 3, The mounting sleeve 3 is provided with an internally threaded hole, a fixing bolt 13 is arranged between the column 2 and the internally threaded hole, a gasket is provided between the fixing bolt 13 and the column 2, and the mounting sleeve 3 There are two sets of upper and lower groups, the lower installation rods 5 are arranged between the installation sleeves 3 on the lower side, the lower sleeves 6 are evenly arranged on the lower installation rods 5, and the installation sleeves 3 on the upper side are provided with An upper mounting rod 8, an upper sleeve 10 is uniformly arranged on the upper mounting rod 8, the lower sleeve 6 and the upper sleeve 10 are arranged oppositely, and the upper sleeve 10 and the lower sleeve 6 are interpose...

Embodiment 2

[0039] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0040] An easy-to-install road guardrail, including all parts in Embodiment 1, also includes:

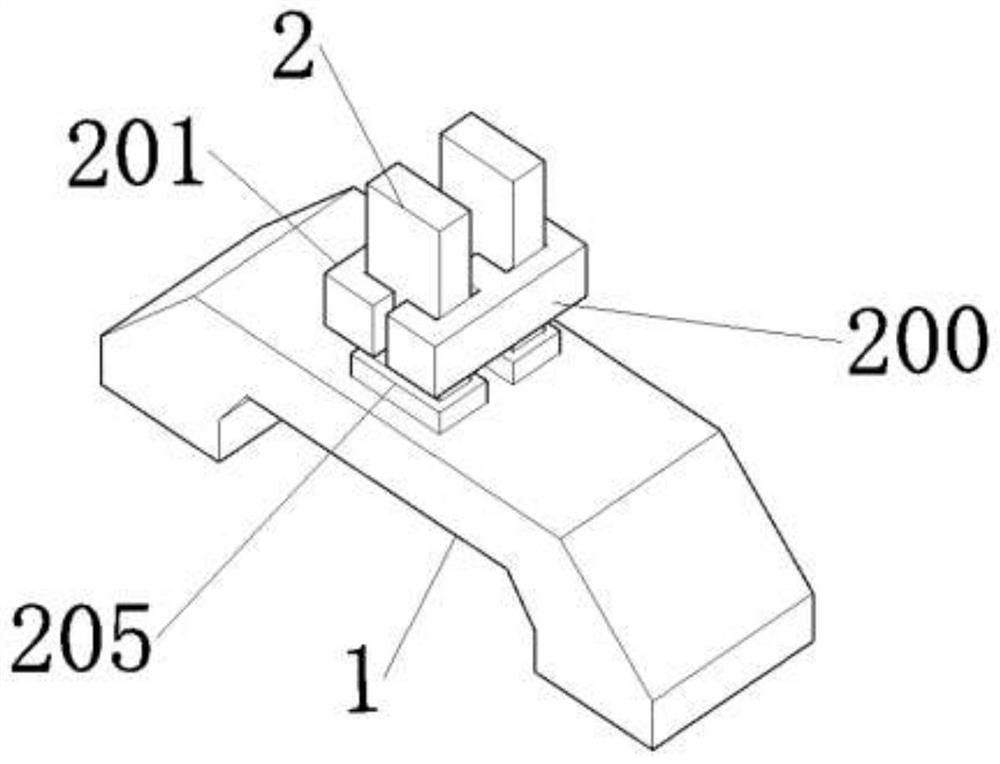

[0041] Further, a fixer is provided between the columns 2, and the fixer includes a first fixing frame 200 and a second fixing frame 201, a groove 203 is arranged in the first fixing frame 200, and the second fixing frame A matching block 204 is arranged on the frame 201 , and the groove 203 and the matching block 204 cooperate with each other.

[0042] Specifically, by setting a fixer between the uprights 2, the first fixing frame 200 and the second fixing frame 201 cooperate with the groove 203 and the matching block 204 to further fix the uprights 2, so as to prevent the uprights 2 from receiving excessive lateral force. Instability due to tension. When installing the fixture, first attach the first fixed frame 200 to the left column 2, then attach the second fixed fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com