Workpiece surface treatment apparatus and workpiece surface treatment method

A technology of workpiece surface and treatment device, applied in the field of workpiece surface treatment device, can solve the problems of contamination of forming molds, troublesome management, increased demand, etc., and achieve the effect of reliable surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

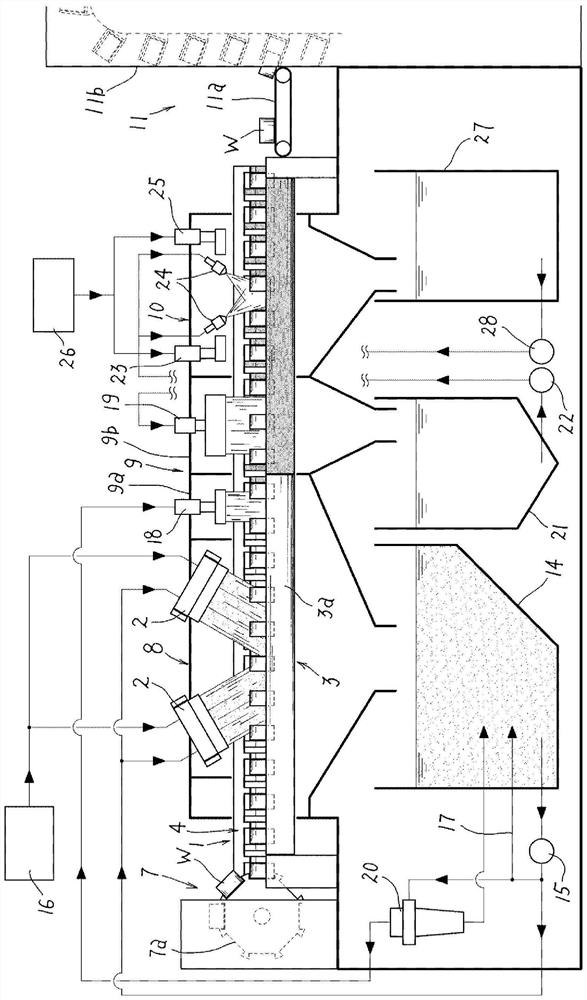

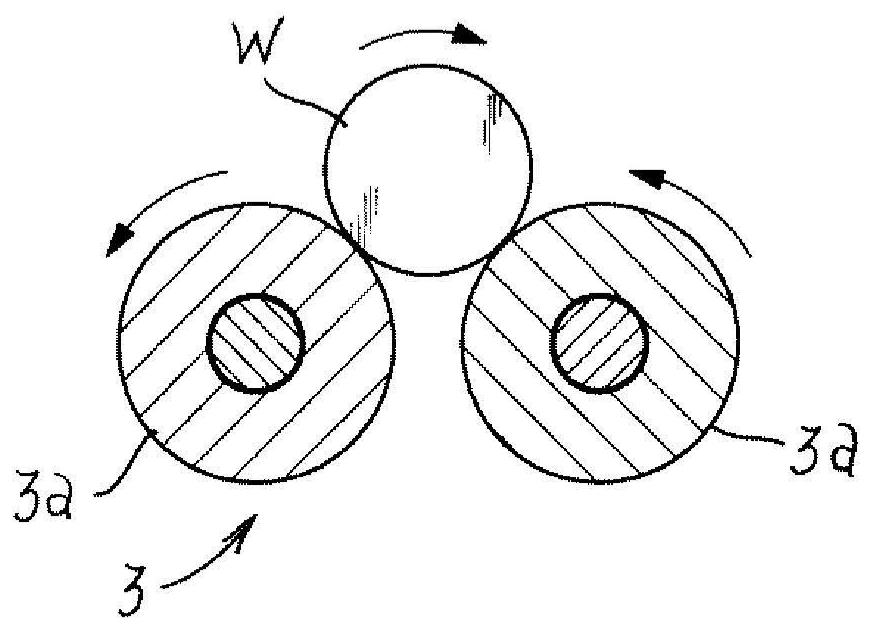

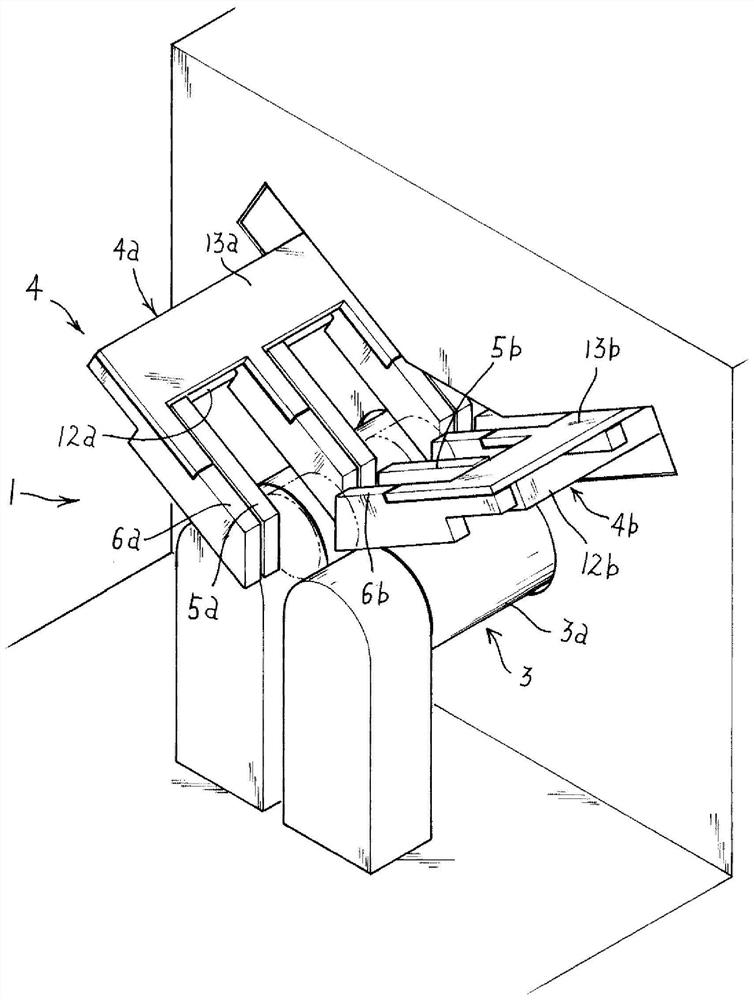

[0045] Specific embodiments of the present invention will be described with reference to the accompanying drawings.

[0046] This embodiment is a case where the workpiece surface treatment apparatus of the present invention is configured as a workpiece surface treatment apparatus for using a cylindrical or disk-shaped forged member for cold forging as a workpiece W, and the workpiece surface treatment apparatus is used for the workpiece W. W applies a lubricant to perform surface treatment to form a lubricating film on the surface of the workpiece.

[0047] Specifically, as figure 1 As shown, the workpiece surface treatment apparatus of the present embodiment includes a workpiece introduction part 7 that guides the workpiece W into the workpiece conveying part 1; a wet blasting unit 8 for wet blasting the workpiece W conveyed by the workpiece conveying unit 1 , a cleaning unit 9 for cleaning the workpiece W that has been wet blasted in the wet blasting unit 8 , The lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com