Vibration-out rod

A small-diameter and large-diameter technology, applied to fishing rods, applications, fishing, etc., can solve the problems of difficult forming and rising manufacturing costs, and achieve the effect of preventing rotation, falling off and cheap fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

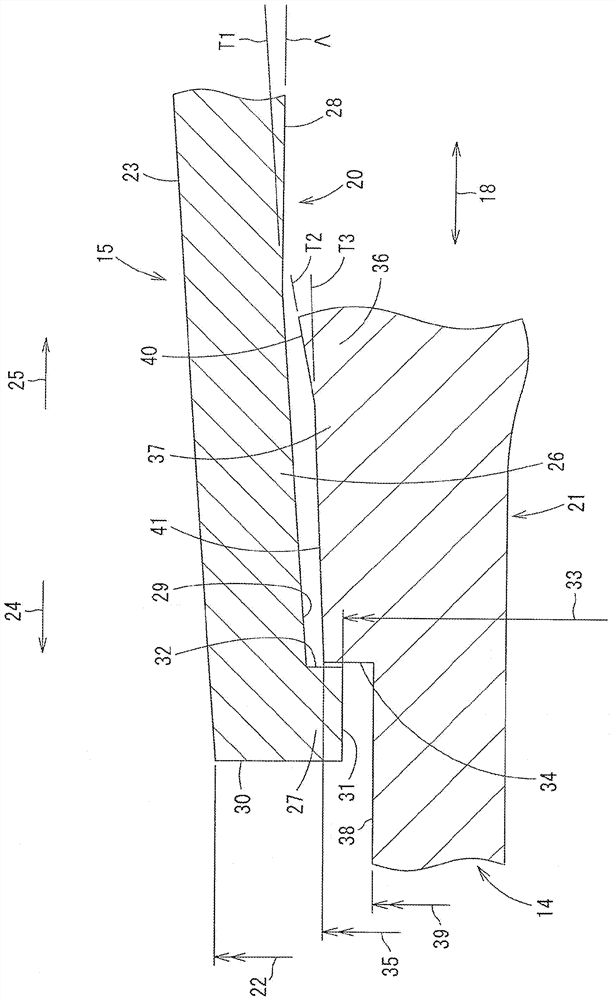

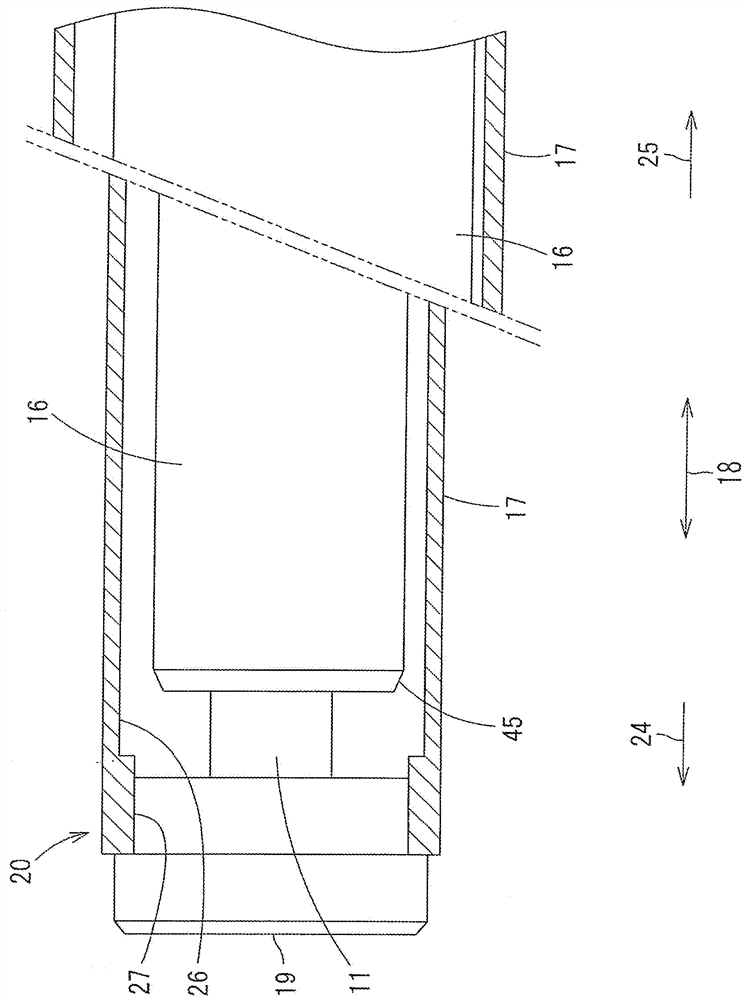

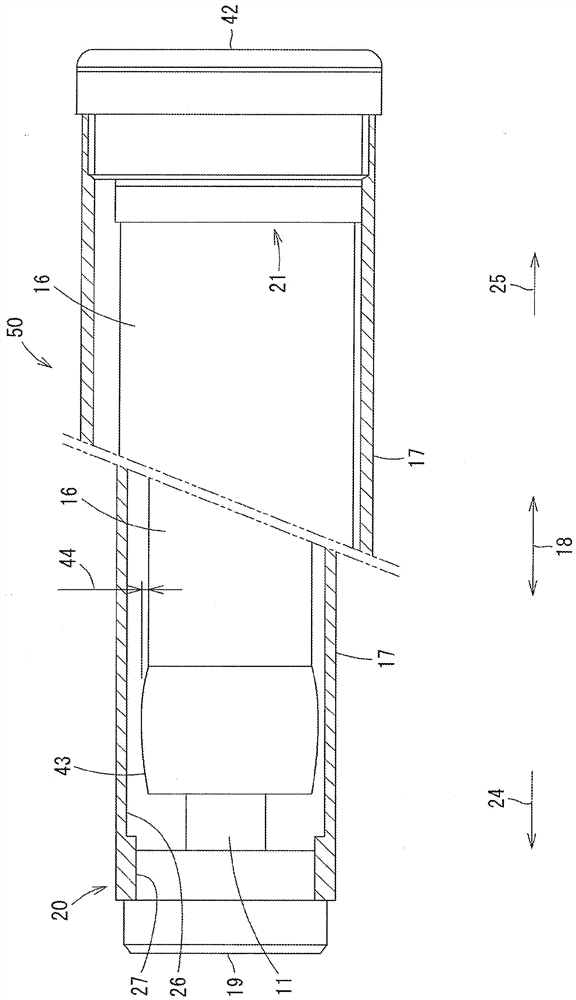

[0031] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings as appropriate. In addition, this embodiment is only one aspect of the vibrating rod of this invention, and it is obvious that embodiment can be changed in the range which does not change the summary of this invention.

[0032] figure 1 It is an external perspective view of a vibrating rod (vibrating rod) 10 according to an embodiment of the present invention.

[0033] This vibrating pole 10 is called a so-called netting pole (タモの支), and a netting is detachably attached to a boss 19 provided at the end. The vibrating rod 10 has seven cylindrical sections 11 to 17 (so-called seven-jointed structure), and as shown in the figure, the respective sections 11 to 17 are assembled in a vibrating manner. That is, the small-diameter node is inserted inside the large-diameter node, and the small-diameter node is slidable in the axial direction 18 relative to the large-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com