Paint spraying device for appearance of board during furniture decoration

A beautiful, wood-based technology, applied in the direction of spraying devices, etc., can solve the problems of dye unevenness, paint damage, etc., and achieve the effects of preventing splashing, easy cleaning, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0056] Example 1

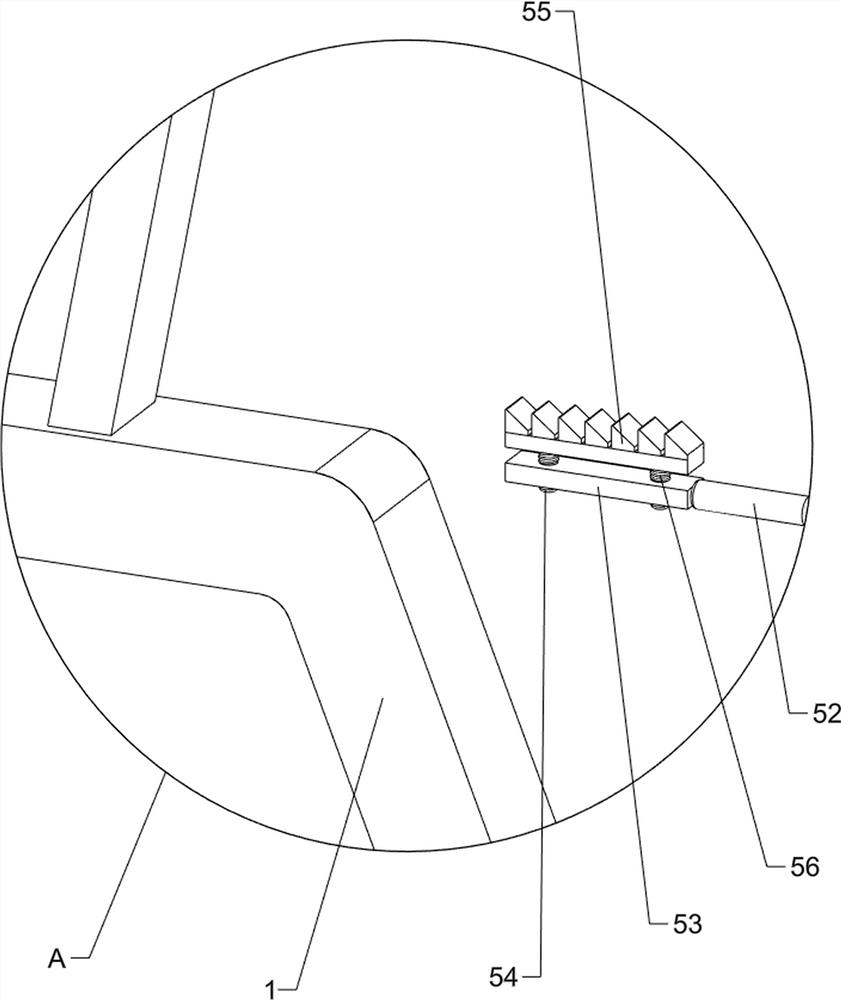

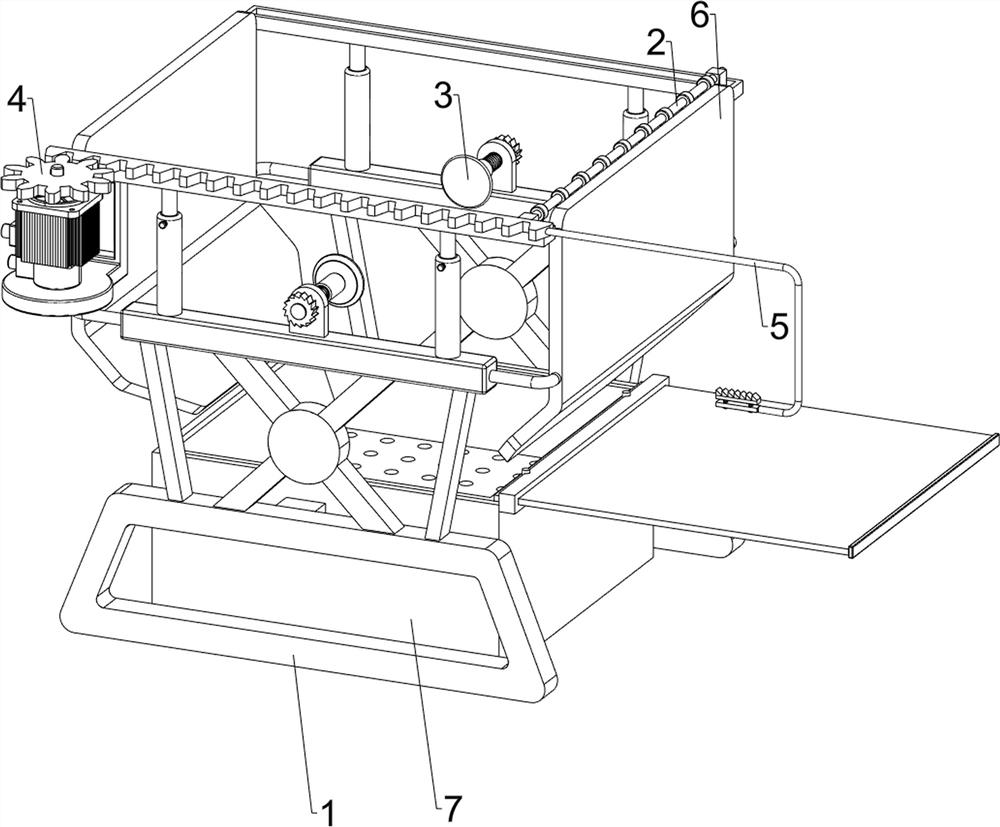

[0057] Furniture decoration beautiful view wooden lacquer, such as figure 1 As shown, including the mounting frame 1, the painting mechanism 2, and the tensioning mechanism 3, and the paint mechanism 2 is connected between the top of the mounting frame 1, and the tensioning mechanism 3 is connected between the top of the mounting frame 1.

[0058] Such as figure 2 As shown, the painting mechanism 2 includes a fixing bar 21, a slider 22, a screw 23, a rail 24, a slider 25, an infusion tube 26, and a spray head 27, and the mounting rack 1 is adjacent to the mounting rod 21, and the fixed bar 21 is provided. The inner average sliding type is provided with a sliding rod 22, and the upper side sliding is slidably equipped with a screw 23 for fixing the slider 22, and there is a slide rail 24 between the top and rear sides of the slide rod 22, and the rail 24 right side. The sliding type is provided with a slider 25, and there is an infusion tube 26 between the slid...

Example Embodiment

[0061] Example 2

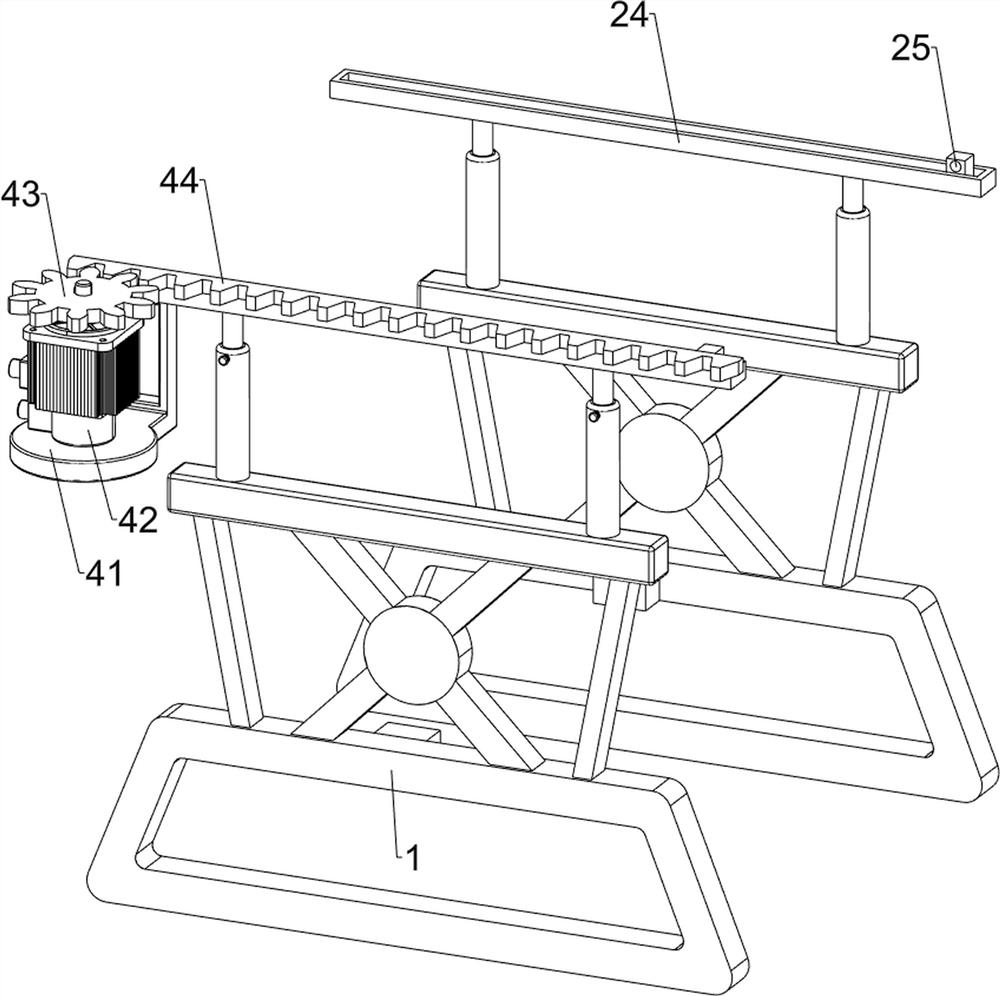

[0062] On the basis of Example 1, such as Figure 4 As shown, there is a drive mechanism 4, the drive mechanism 4 includes a placement plate 41, a servo motor 42, a whole gear 43, and a full rack strip 44, and a placement plate 41 is provided on the left side of the front side rail 24, on the plate 41. A servo motor 42 is provided, and the servo motor 42 output shaft is provided with a total gear 43, and a full range strip 44 is provided on the front side of the front side slider 25, and the whole rack 44 meshes with the whole gear 43.

[0063] After the board is placed, the servo motor 42 is activated, the servo motor 42 outputs the axis rotation to rotate the whole gear 43, and the whole gear 43 rotates to move the whole rack 44 to the left, and the whole rack 44 moves to the left slider 25 To the left, the infusion tube 26 and the nozzle 27 are moved to the left, and when the slider 25 is moved to the left side, the servo motor 42 outputs the axial reverse dir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap