Paper arranging device used before corrugated paper laying of paper feeder

A paper feeder and tile-laying technology, applied in the directions of transportation and packaging, separation of objects, separation of piles, etc., can solve the problems that the bottom sheet of the positioning rod cannot be aligned, the other sheets cannot be well aligned, and the friction force is large. Improve the effect of paper management, solve the instability of paper feeding, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

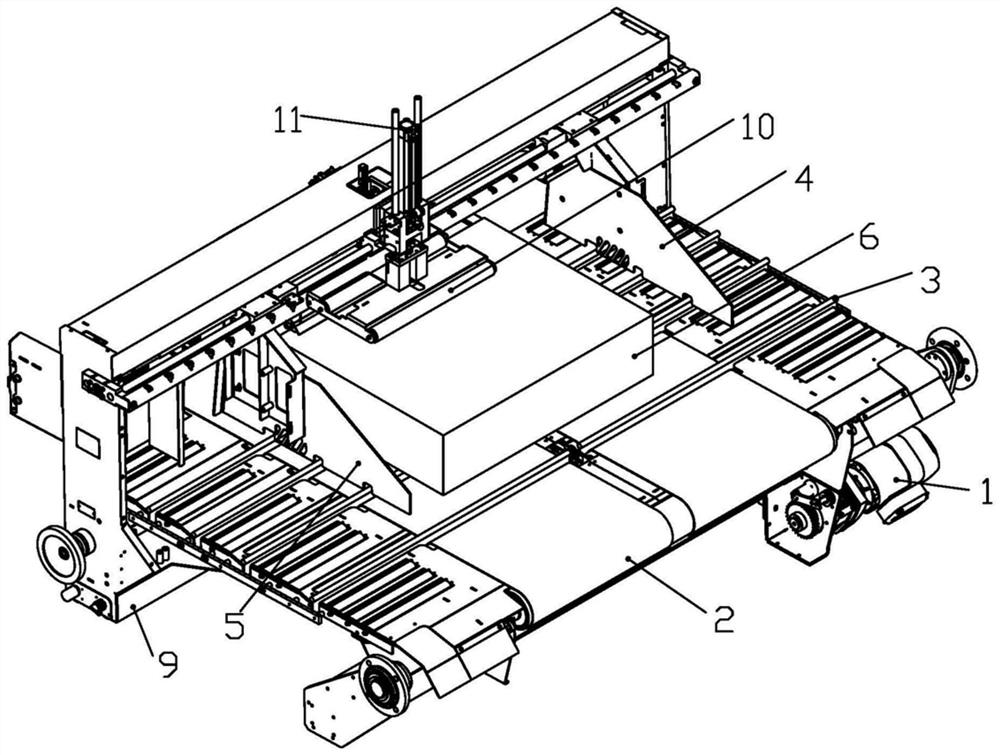

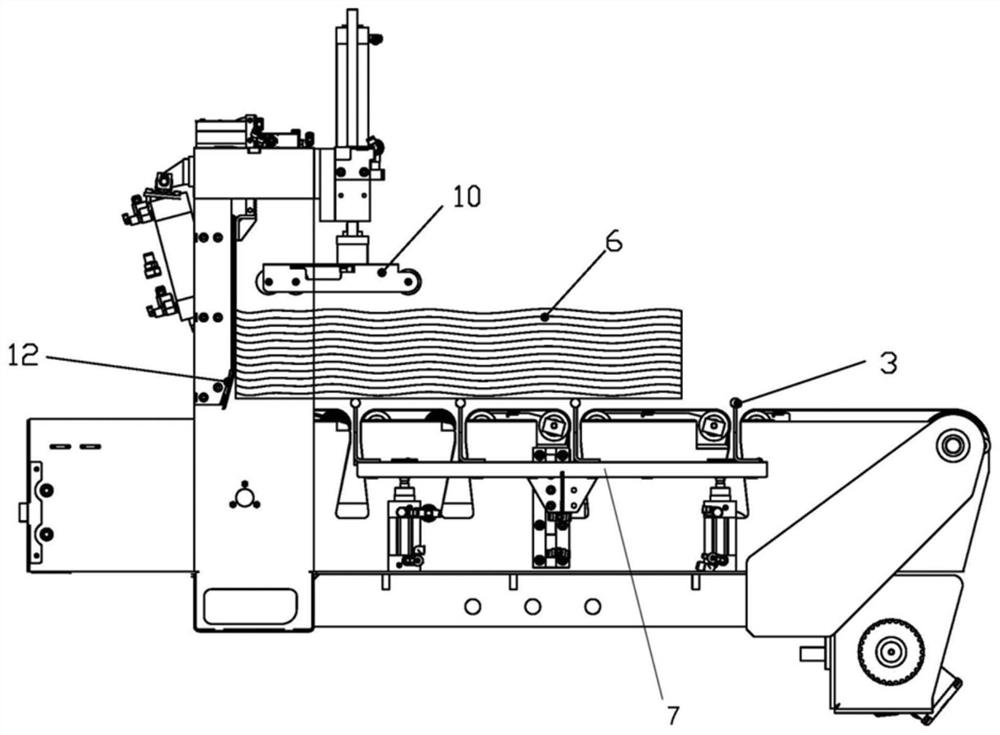

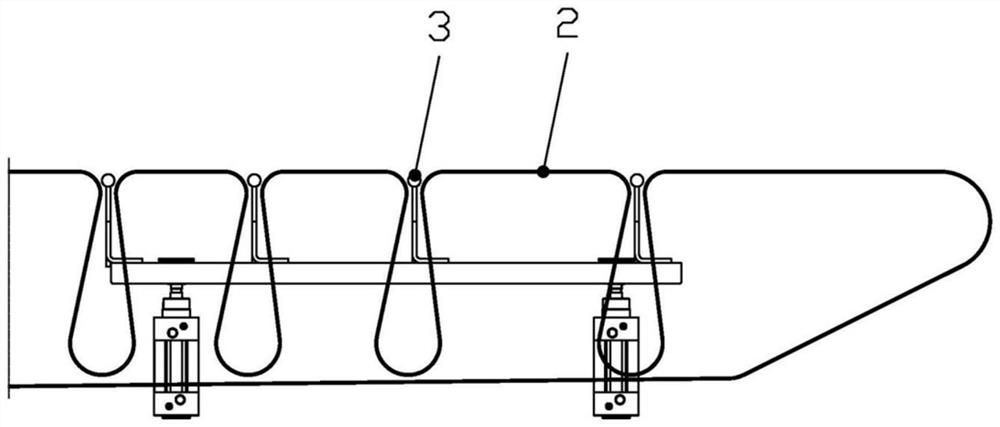

[0030] Such as figure 1 As shown, this embodiment is a paper finishing device before the paper feeder is tiled, including a frame 9, which is connected with a side clapping mechanism, a belt conveying mechanism for transporting the paper pile 6, and a front baffle 12. The side shooting mechanism is located above the two sides of the belt conveying mechanism. The front baffle 12 is located at the rear end of the belt conveying mechanism. 5 and the second side beat driving cylinder, the first transmission surface side beat 4 is fixedly connected to the first side beat drive cylinder and driven by it, and the second operation surface side beat 5 is fixedly connected to the second side beat drive cylinder and driven by it , the first transmission side side beater 4 and the second operation side side beater 5 are located above the belt conveyor on both sides respectively, and the first side beater drive cylinder and the second side beater drive cylinder are fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com