High-cold-resistance porcelain insulator and manufacturing process thereof

A porcelain insulator and manufacturing process technology, applied in the field of electric power engineering auxiliary equipment, can solve the problems of cracking of the surface coating of the porcelain insulator, affecting normal use, inconvenient disassembly, etc., and achieving the effect of reducing the contact area, facilitating maintenance work, and reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

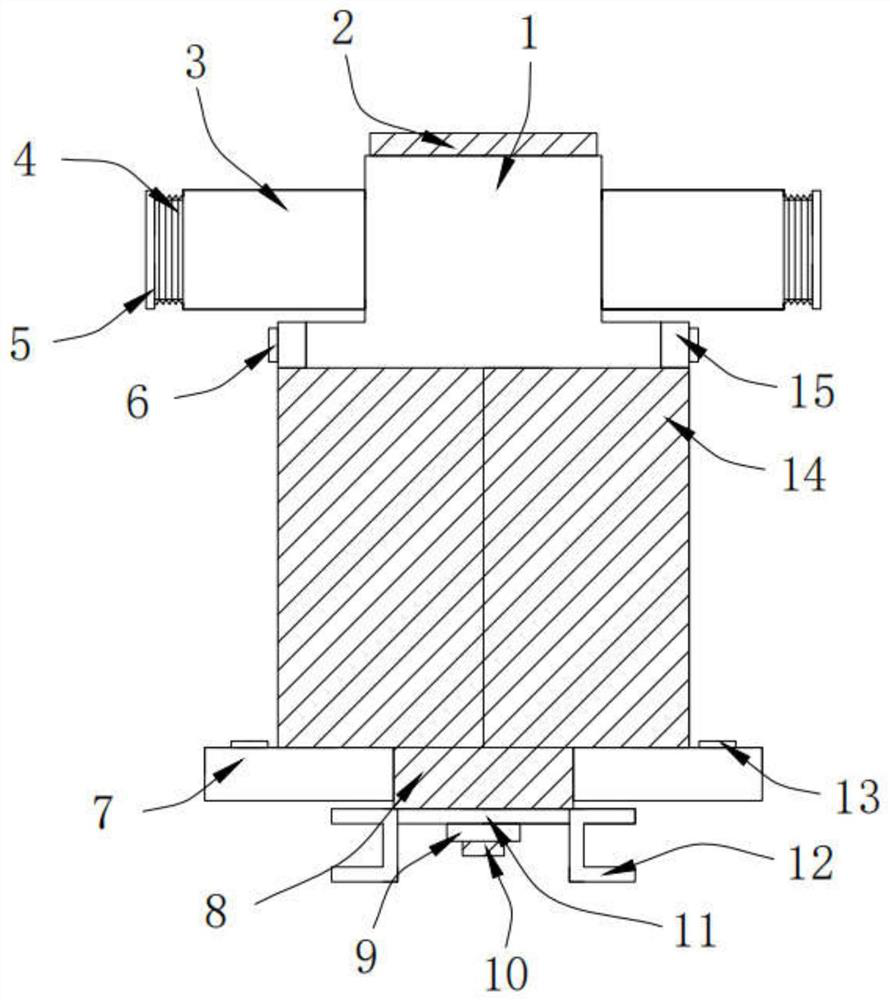

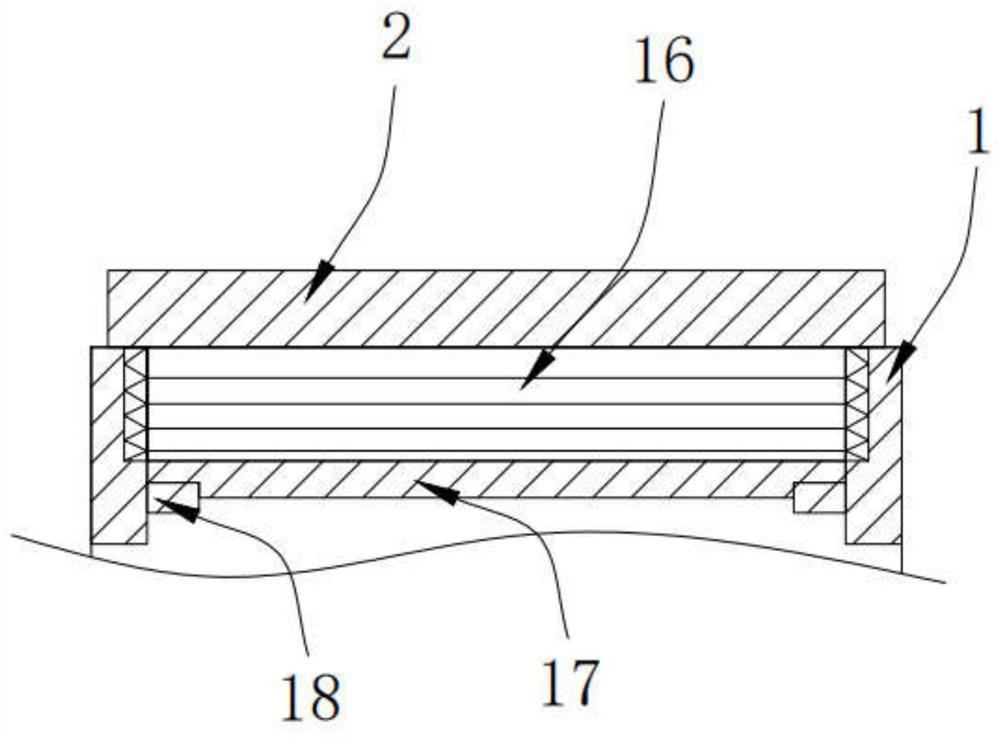

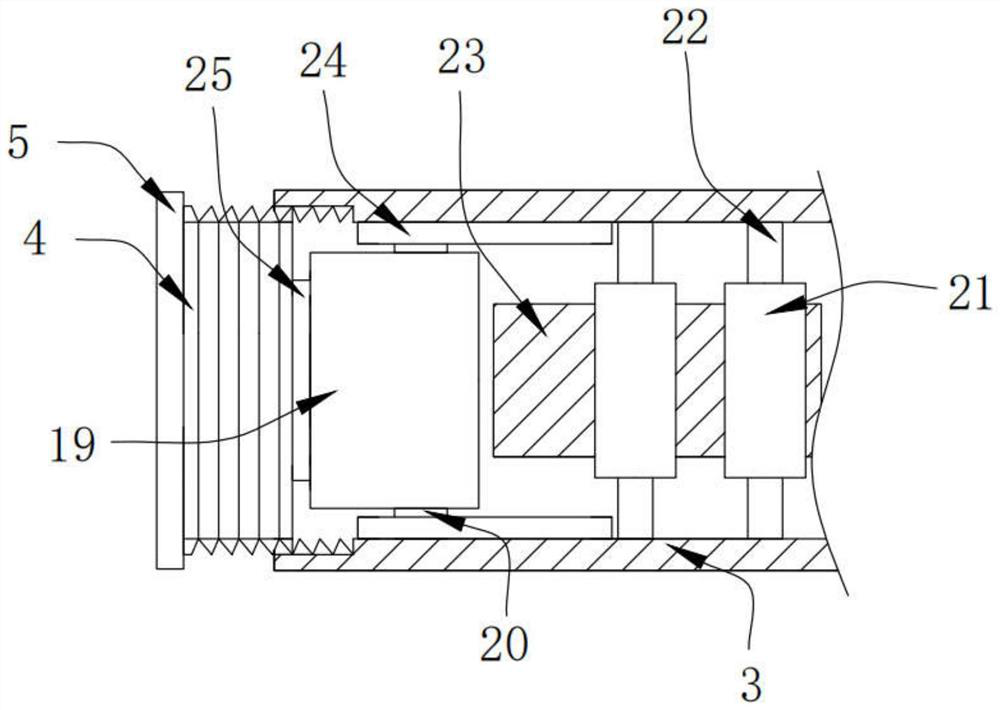

[0029] see Figure 1-6 , the present invention provides a technical solution: a high cold resistance porcelain insulator, including a porcelain umbrella group 36, the top of the porcelain umbrella group 36 is equipped with a first shell 1, and two sides of the first shell 1 are welded The second housing 3, one side of the second housing 3 communicates with the first housing 1, the bottom of the porcelain umbrella group 36 is equipped with a third housing 8, and the bottom of the third housing 8 is welded with a second fixing plate 11 A steel foot bolt 10 is installed on one side of the second fixing plate 11, a gasket 9 is set on one side of the steel foot bolt 10, two first fixing plates 7 are welded on both sides of the third housing 8, the first One side of the fixed plate 7 is provided with two arc-shaped plates 14, and one side of the arc-shaped plates 14 is welded with a threaded orifice plate 15, and the internal thread of the threaded orifice plate 15 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com