Anti-freezing heating device of telescopic sluice mechanical arm

A heating device and robotic arm technology, applied in water conservancy projects, water conservancy engineering equipment, sea area engineering, etc., can solve problems such as unfeasible heating devices, failure to work normally, damage to heating devices, etc., and achieve stable and effective heating work and maintenance work Convenience and guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

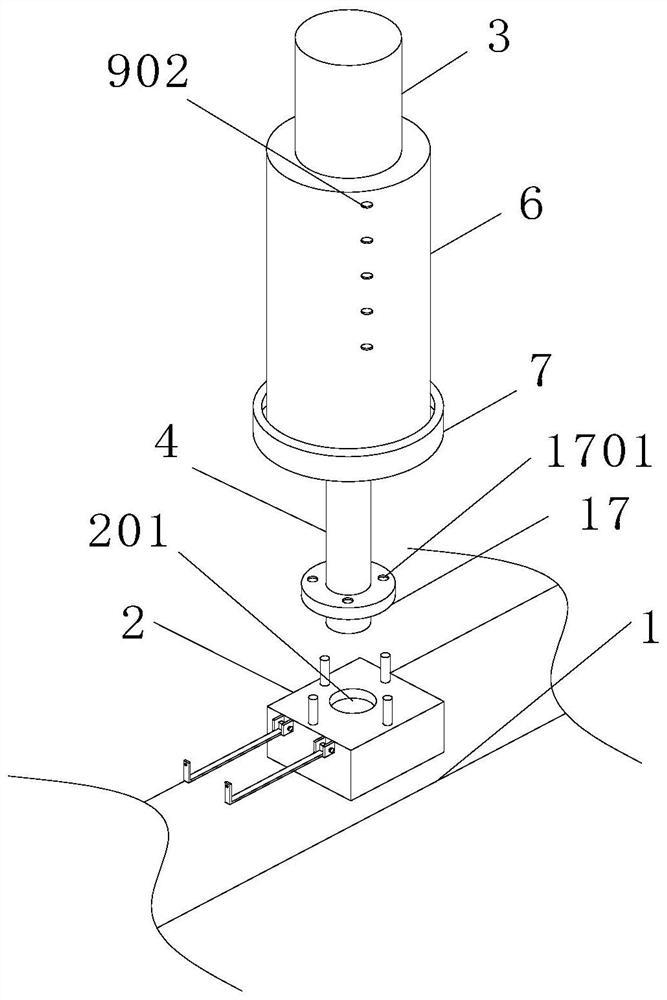

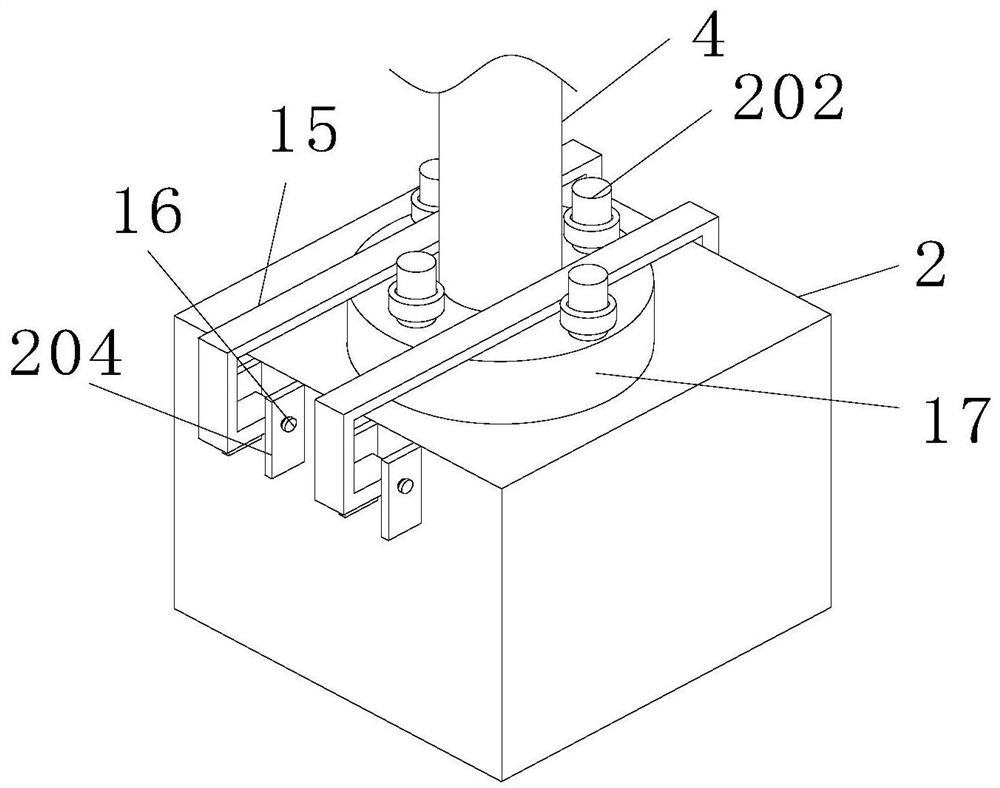

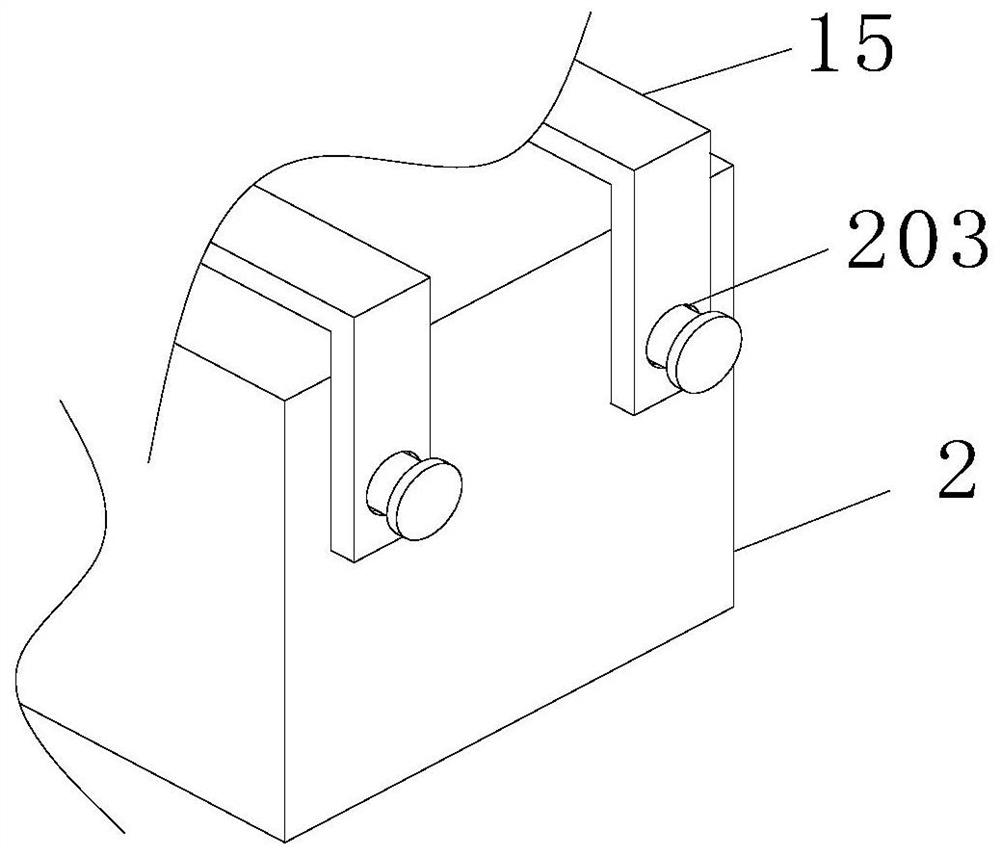

[0033] The embodiment of the present invention discloses a sleeve type sluice mechanical arm antifreeze heating device, such as Figure 1-8 As shown, including the gate 1, the upper surface of the gate 1 is fixedly connected with the fixed block 2, the upper surface of the fixed block 2 is fixedly clamped with the outer cylinder 3, the inner cavity of the outer cylinder 3 is sleeved with the inner cylinder 4, and the inner cylinder 4 The lower surface is fixedly clamped with the fixed block 2, the side wall of the outer cylinder 3 is fixedly connected with the inner sleeve 5, the side wall of the outer cylinder 3 is fixedly connected with the ring block 301, and the upper surface of the ring block 301 is fixedly connected with the threaded column 302, The threaded column 302 passes through the through groove 802 and extends to the outer wall of the outer sleeve 6. The extension end of the threaded column 302 is threadedly connected by a nut, and the threaded column 302 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com